Description

| Parameter name | Parameter value |

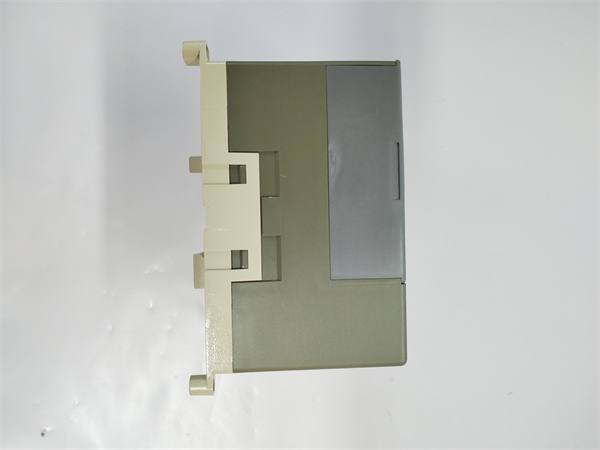

| Product model | 07AI91 |

| Manufacturer | ABB |

| Product category | Analog Input Module |

| Rated input | Supports multiple input ranges, such as 0 – 10 VDC, 4 – 20 mA. For 0 – 10 VDC input, the input impedance is typically high (e.g., 100 kΩ) to minimize loading effects on the source; for 4 – 20 mA input, the input resistance is designed to be around 250 Ω to convert the current signal to a voltage for processing. |

| Output capabilities | Converts analog input signals into digital values that can be easily processed by a control system. It provides accurate digital representations corresponding to the analog input levels within its configured range. |

| Communication interfaces | Connects to a control system through a fieldbus interface, such as Profibus DP or Modbus. In Profibus DP communication, it can transfer data at high speeds, with a baud rate typically adjustable from 9.6 kbps to 12 Mbps, ensuring fast and reliable data exchange. |

| Dimensions (LxWxH) | Approximately 100 mm x 50 mm x 70 mm. Its compact size allows for easy installation in control cabinets, even in space – constrained environments. |

| Weight | Around 0.2 kg, which is lightweight, facilitating handling and installation. |

| Operating temperature | – 20°C to + 60°C. This wide temperature range makes it suitable for use in various industrial settings, including both indoor and outdoor applications with proper enclosure protection. |

| Storage temperature | – 40°C to + 85°C. It can be stored under these temperature conditions without degrading its performance for an extended period. |

| Mounting method | DIN – rail mountable. It can be quickly and securely attached to a standard 35 – mm DIN rail, following the standard industrial mounting practices. |

| Certifications | CE certified, indicating compliance with European safety, health, and environmental protection standards. It also meets relevant industry – specific certifications, such as IEC 61131 – 2 for industrial automation applications. |

ABB 07AI91

Product introduction

The 07AI91 by ABB is a high – performance analog input module, designed to meet the complex requirements of industrial control systems. As an integral part of ABB’s comprehensive range of automation products, this module plays a crucial role in converting real – world analog signals, such as temperature, pressure, and flow rate, into digital data that can be processed by programmable logic controllers (PLCs), distributed control systems (DCS), or other industrial control units.

Constructed with top – grade materials and leveraging ABB’s advanced manufacturing expertise, the 07AI91 ensures long – term reliability and stable performance. It is engineered to interface seamlessly with other ABB automation components as well as third – party devices, making it a flexible choice for system integrators and end – users across diverse industries.

Core advantages and technical highlights

High – precision signal conversion

The 07AI91 incorporates advanced analog – to – digital conversion technology. With a high – resolution analog – to – digital converter (e.g., 16 – bit or higher), it can accurately convert analog input signals into digital values. This high precision enables it to distinguish even small changes in the input signal. For example, in a chemical process where precise temperature control is critical, the 07AI91 can detect temperature variations as small as 0.1°C, ensuring that the process operates within the desired parameters.

Multiple input range flexibility

This module supports a wide range of analog input signals, including common voltage ranges like 0 – 10 VDC and current ranges such as 4 – 20 mA. This flexibility allows it to be used with various types of sensors and transducers. In a water treatment plant, it can interface with both pressure sensors that output a 4 – 20 mA signal and temperature sensors that provide a 0 – 10 VDC signal, eliminating the need for multiple specialized input modules.

Reliable communication interface

Equipped with a fieldbus communication interface, such as Profibus DP or Modbus, the 07AI91 can efficiently communicate with the control system. The Profibus DP interface, in particular, offers high – speed data transfer capabilities, ensuring that the digital values of the analog inputs are quickly and accurately transmitted to the control unit. In a large – scale manufacturing plant with multiple control nodes, the fast communication speed of the 07AI91 helps in real – time monitoring and control of the production process.

Robust design for harsh environments

The 07AI91 features a rugged housing that protects against physical damage, dust, and moisture. Its internal components are carefully selected and designed to withstand electrical noise and vibrations commonly found in industrial environments. In a steel mill, where there are high levels of electromagnetic interference and mechanical vibrations, the 07AI91 can continue to operate reliably, providing accurate analog input data to the control system.

Typical application scenarios

Process control in manufacturing

In a food and beverage manufacturing plant, the 07AI91 can be used to monitor and control various process variables. It can connect to sensors that measure the temperature of the product during cooking, the pressure of the filling machines, and the flow rate of ingredients. By accurately converting these analog signals into digital data, the control system can adjust the process parameters in real – time, ensuring product quality and production efficiency. For instance, if the temperature of the cooking process deviates from the setpoint, the control system, based on the data from the 07AI91, can adjust the heating element’s power to bring the temperature back to the desired level.

Environmental monitoring in industrial plants

Industrial plants often need to monitor environmental factors such as air quality and humidity. The 07AI91 can interface with gas sensors that measure the concentration of pollutants in the air (outputting an analog signal) and humidity sensors that provide a voltage proportional to the humidity level. In a pharmaceutical manufacturing facility, where maintaining a clean and controlled environment is crucial, the 07AI91 can transmit the environmental data to the central control system. If the air quality deteriorates or the humidity exceeds the acceptable range, the system can trigger alarms and activate ventilation or air – conditioning systems to correct the situation.

Energy management in buildings

In large commercial buildings, the 07AI91 can be part of the energy management system. It can connect to sensors that measure the power consumption of different electrical equipment, such as lighting fixtures, HVAC units, and elevators. By converting the analog power – measurement signals into digital data, the energy management system can analyze the energy usage patterns. During off – peak hours, the system can use the data from the 07AI91 to identify and reduce the power consumption of non – essential equipment, thereby achieving energy savings.

ABB 07AI91

Related model recommendations

07AI92: A more advanced version of the 07AI91, offering additional features such as higher channel density (e.g., more analog input channels in the same physical size), enhanced accuracy, and improved noise immunity. It is suitable for applications where a large number of analog input signals need to be processed with high precision, such as in a large – scale industrial process control system with numerous sensors.

07AI81: A lower – cost alternative with similar basic functionality. It may have a slightly lower resolution analog – to – digital converter or a more limited set of input range options. This model is ideal for small – scale industrial applications or projects with a tight budget where the requirements for signal precision and flexibility are not as stringent.

07AI91 – EX: A variant of the 07AI91 designed for use in explosive environments. It has additional safety features and certifications, such as ATEX or IECEx, to ensure safe operation in areas where there is a risk of explosion due to the presence of flammable gases or dust. This model is suitable for applications in the oil and gas industry, petrochemical plants, and mining operations.

Installation, commissioning and maintenance instructions

Installation preparation

Before installation, carefully review the product manual provided by ABB. Ensure that the installation location meets the environmental requirements in terms of temperature, humidity, and electrical interference. Mount the 07AI91 on a 35 – mm DIN rail in a suitable control cabinet, following the provided mounting guidelines. Make sure to leave sufficient space around the module for proper ventilation. Check all electrical connections and use appropriate shielded cables to minimize interference. Terminate the cables securely, ensuring that the connections for the analog inputs and the fieldbus communication are correctly wired.

Commissioning

Power on the system and use the appropriate configuration software (e.g., ABB’s dedicated PLC programming software) to set up the 07AI91. Configure the input ranges according to the sensors connected to the module. Calibrate the module if necessary to ensure accurate signal conversion. Test the communication with the control system by sending sample analog signals to the module and verifying that the corresponding digital values are correctly received by the control unit. Check for any error messages or abnormal behavior during the commissioning process.

Maintenance suggestions

Regularly inspect the 07AI91 for any signs of physical damage, such as cracks in the housing or loose connections. Monitor the operating temperature of the module, as overheating can affect its performance. Check the input signals periodically to ensure that they are within the expected range. Clean the module if it is in a dusty environment to prevent dust accumulation, which could cause electrical problems. Update the firmware (if available) to benefit from the latest features and bug fixes provided by ABB. If any issues are detected, refer to the product manual or contact ABB’s technical support for troubleshooting guidance.

Service and guarantee commitment

ABB offers a standard warranty of [X] years on the 07AI91, covering manufacturing defects. During this period, if the module malfunctions due to such defects, ABB will provide repair or replacement services free of charge. ABB’s global technical support team is available 24/7 to assist customers with any installation, commissioning, or maintenance issues. Customers can access online resources, including user manuals, technical documentation, and software updates, through ABB’s customer portal. In case of complex problems, ABB can also provide on – site support services. This commitment reflects ABB’s confidence in the quality and reliability of the product and its dedication to ensuring customer satisfaction.