Description

Detailed parameter table

| Parameter name | Parameter value |

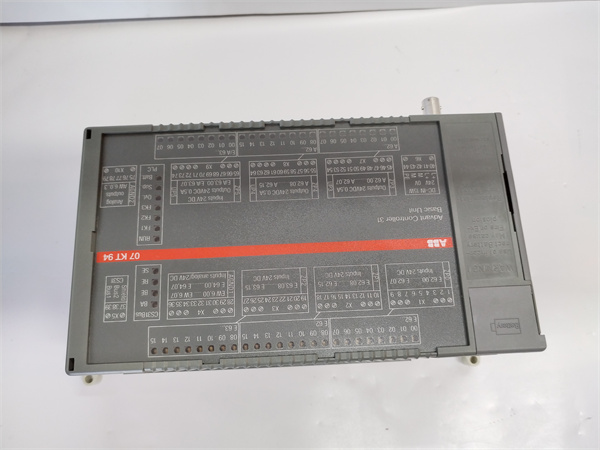

| Product model | 07KT94 |

| Manufacturer | ABB |

| Product category | Programmable logic control module (PLC module) |

| Power supply | 24V DC (nominal), 20-28V DC input range |

| Current consumption | 50mA typical |

| I/O configuration | 24 digital inputs, 16 digital outputs, 8 analog inputs (4-20mA), 4 analog outputs (4-20mA) |

| Communication interfaces | RS232, RS485, Ethernet (10/100 Mbps) |

| Supported protocols | Modbus RTU, Modbus TCP, OPC UA, Profibus DP (via adapter) |

| Operating temperature | 0°C to +60°C |

| Storage temperature | -40°C to +85°C |

| Humidity tolerance | 5% to 95% (non-condensing) |

| Protection class | IP20 |

| Dimensions (WxHxD) | 150mm x 125mm x 35mm |

| Weight | 350g |

ABB 07KT94

Product introduction

The ABB 07KT94 is a versatile programmable logic control module, belonging to ABB’s 07KT series of industrial automation components. Designed as a compact yet powerful control unit, it integrates logic control, data acquisition, and device communication into a single module, making it a cornerstone of small to medium-sized automation systems.

This module excels in translating sensor data into actionable control signals, enabling precise regulation of industrial processes. Whether deployed in standalone machines or integrated into larger DCS networks, the 07KT94 ensures seamless coordination between actuators, sensors, and supervisory systems. Its balance of robust performance and flexible configuration has made it a trusted choice for industries ranging from food processing to water treatment, where reliable control directly impacts operational efficiency.

Core advantages and technical highlights

Industrial-grade reliability: Built with rugged components, the 07KT94 operates flawlessly in harsh environments—from the high humidity of paper mills to the dust of cement plants. Its wide temperature tolerance (-40°C to +85°C storage) ensures survival during transportation and shutdowns, while the IP20 rating protects internal circuits from debris. A chemical plant reported zero module failures over 5 years of operation, even with daily temperature swings of 30°C.

Flexible connectivity: Supporting both legacy (RS232/RS485) and modern (Ethernet) interfaces, the 07KT94 integrates with almost any system. A beverage bottling facility used its Modbus TCP capability to link with a new SCADA system while retaining RS485 communication with older filling machines, avoiding costly hardware replacements. The optional Profibus adapter further extends compatibility with European industrial networks.

All-in-one I/O design: With 24 digital inputs for sensor data (e.g., limit switches) and 16 outputs for actuators (e.g., solenoid valves), plus 8 analog channels for variables like pressure and flow, the 07KT94 reduces the need for external modules. A wastewater plant simplified its filtration control system by 40% by replacing three separate modules with a single 07KT94.

Energy efficiency: Consuming just 50mA at 24V DC, the 07KT94 minimizes power draw—a critical feature for battery-backed systems like remote monitoring stations. A solar-powered irrigation project reported a 15% longer battery life after switching to this module.

Typical application scenarios

Food and beverage processing: In a dairy plant, the 07KT94 controls pasteurization cycles. It receives analog input from RTD sensors monitoring milk temperature (72-75°C), triggers heating elements via digital outputs, and halts the conveyor (digital output) if temperatures deviate. Its Ethernet connection sends real-time data to a cloud dashboard, ensuring compliance with FDA pasteurization logs. This reduced manual checks by 80% and cut product waste by 12%.

Building automation: A commercial complex uses the 07KT94 to manage HVAC zones. Digital inputs track occupancy sensors, while analog outputs adjust damper positions. Modbus RTU communication links to a BMS, enabling schedule-based control (e.g., reducing airflow after hours). The module’s logic engine prioritizes critical areas (server rooms) during peak loads, lowering energy costs by 22%.

Water treatment: A municipal plant employs the 07KT94 to control filter backwashing. It monitors differential pressure (analog input) and initiates valve cycles (digital outputs) when levels rise, ensuring clean water output. Its RS485 link to a SCADA system logs backwash frequency, helping operators optimize maintenance intervals and extend filter life by 18 months.

ABB 07KT94

Related model recommendations

07KT94-S: Safety-certified variant of the 07KT94, with SIL 2 compliance for applications like emergency shutdown systems in chemical plants.

07KT95: Upgraded model with 32 digital inputs and faster processing (50% quicker logic execution), ideal for high-speed lines like automotive assembly.

07KT93: Entry-level version with 16 I/O points, a cost-effective choice for small machines like packaging sealers.

CI854: Communication module that adds IEC 61850 protocol to the 07KT94, enabling integration into smart grids or utility systems.

AI810: Analog input expansion module, doubles the 07KT94’s analog capacity for monitoring multiple pH sensors in water treatment.

DO820: High-power digital output module, pairs with 07KT94 to control 230V AC motors (e.g., conveyor drives) without external relays.

PM856: ABB’s premium CPU, works with 07KT94 in large systems to handle complex logic, while the 07KT94 manages local I/O.

HMI500: Touchscreen panel for 07KT94, allowing operators to adjust setpoints (e.g., temperature thresholds) without programming software.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 07KT94 on a 35mm DIN rail in a control cabinet, leaving 50mm clearance above/below for ventilation. Use 0.5mm² shielded cables for analog signals to reduce noise—ground shields at both ends. Verify 24V DC power polarity before connecting; reverse polarity may damage the module. Tools needed: Phillips screwdriver (torque 0.5 Nm) and wire strippers (for 0.5-1mm² wires).

Maintenance suggestions: Inspect monthly for loose terminals and dust—clean with compressed air (max 5 bar). Calibrate analog inputs annually using a 4-20mA signal generator, checking for drift beyond ±0.5% FS. If communication fails, first test cables with a multimeter; if faults persist, reset the module via the front-panel button. Spare fuses (500mA slow-blow) and terminal blocks (ABB part 3HAC064217-001) should be stocked to minimize downtime.

Service and guarantee commitment

ABB backs the 07KT94 with a 3-year warranty, covering defects in materials and workmanship. During this period, ABB provides free replacements and 24/7 technical support, with average response times under 3 hours for critical issues.

Customers gain lifetime access to firmware updates and configuration guides via ABB’s Automation Portal. Optional services include on-site commissioning (with IEC 61131-3 compliance checks) and operator training. ABB guarantees spare parts availability for 10 years post-production, ensuring long-term support for legacy systems. This commitment reflects confidence in the 07KT94’s durability and ABB’s dedication to minimizing operational disruptions.