Description

07KT97F1: Product Overview

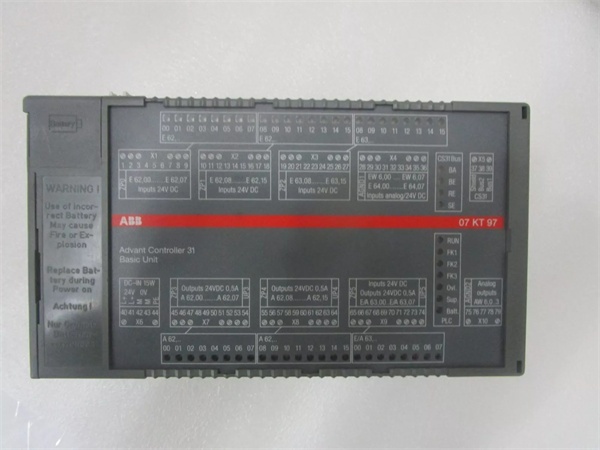

The ABB 07KT97F1 is a compact, high-performance base unit belonging to ABB’s Advant Controller 31 series, designed for decentralized industrial automation systems. As the “brain” of the Advant Controller 31 architecture, it integrates digital/analog I/O, communication interfaces, and real-time processing capabilities to enable precise control of industrial processes—from manufacturing lines to utility systems.

Role in Automation Systems:

Positioned as a decentralized automation controller, the 07KT97F1 acts as either a standalone unit for small-scale applications or a slave device (remote processor) in larger systems. It bridges the gap between field devices (sensors, actuators) and higher-level control systems (e.g., SCADA, MES), executing control logic, processing data, and facilitating communication across the automation ecosystem.

Core Functionality:

-

I/O Processing: Handles 24 digital inputs (for switches, sensors) and 16 digital outputs (for relays, solenoids), plus 8 analog inputs (for temperature, pressure) and 4 analog outputs (for valve positioning, motor speed).

-

Communication: Equipped with a CS31 system bus interface for system expansion and 2 serial ports (COM1/COM2) compatible with MODBUS, enabling seamless integration with third-party devices and上位 systems.

-

Real-Time Control: Features a 50 kHz counter (configurable in 7 modes) for precise timing and counting tasks, critical for applications like batch processing or motion control.

-

Data Storage: Offers 480 kB of user program space and 256 kB of data storage, supporting complex control algorithms and historical data logging.

Platform Benefits (Advant Controller 31 Series):

The 07KT97F1 leverages ABB’s legacy of reliability in industrial automation, with benefits including:

-

Decentralization: Reduces wiring complexity by placing control logic closer to field devices, improving system responsiveness.

-

Scalability: Supports expansion via CS31 bus-connected modules, adapting to growing operational needs.

-

Ease of Use: Removable screw terminals and DIN rail mounting simplify installation and maintenance.

ABB 07KT97F1

Technical Specifications

Model Number: 07KT97F1

Manufacturer: ABB

Product Type: Advant Controller 31 Base Unit

-

Power Supply: 24 VDC (±10%)

-

Digital Inputs: 24 (24 VDC, LED indication)

-

Digital Outputs: 16 (transistor, 24 VDC, 0.5 A max, LED indication)

-

Analog Inputs: 8 (configurable for 0–10 V, ±10 V, 0–20 mA, 4–20 mA; differential or single-ended)

-

Analog Outputs: 4 (configurable for ±10 V, 0–20 mA, 4–20 mA)

-

Counters: 2 (50 kHz max frequency, 7 operating modes)

-

Communication Interfaces:

-

1 CS31 system bus port (for module expansion)

-

2 serial ports (COM1/COM2; MODBUS RTU/ASCII compatible)

-

-

Memory: 480 kB user program space, 256 kB data storage

-

Real-Time Clock: Built-in (battery-backed for power outages)

-

Operating Temperature: 0°C to +55°C (32°F to 131°F)

-

Storage Temperature: -25°C to +70°C (-13°F to 158°F)

-

Humidity: 5% to 95% non-condensing

-

Dimensions (W×H×D): 160 mm × 120 mm × 100 mm (6.3 in × 4.7 in × 3.9 in)

-

Weight: 0.8 kg (1.8 lbs)

-

Certifications: CE, UL, RoHS

Core Features & Customer Value

1. Flexible I/O Configuration:

The 07KT97F1’s 24 digital inputs and 16 digital outputs (plus 8 analog inputs/4 analog outputs) cater to a wide range of field devices, from simple limit switches to precision pressure transducers. For example, a manufacturing plant can use the digital inputs to monitor conveyor belt sensors and the analog outputs to adjust motor speeds—all with a single module.

2. Seamless Communication:

The CS31 system bus interface allows expansion with additional I/O or communication modules, while the MODBUS-compatible serial ports enable integration with legacy systems (e.g., Siemens S7-300 PLCs). This flexibility reduces the need for costly protocol converters, saving time and money during system upgrades.

3. Real-Time Performance:

The 50 kHz counter and fast I/O response time (<1 ms) ensure precise control of dynamic processes, such as bottling lines or robotic assembly. For customers, this translates to higher product quality and reduced waste.

4. Easy Installation & Maintenance:

Removable screw terminals and DIN rail mounting make the 07KT97F1 easy to install in control cabinets, even in space-constrained environments. The LED indicators for inputs/outputs simplify troubleshooting, reducing downtime and maintenance costs.

ABB 07KT97F1

Typical Applications

The ABB 07KT97F1 is widely used in industries requiring decentralized automation and real-time control:

-

Manufacturing:

-

Controls conveyor belts, robotic arms, and assembly-line equipment in automotive or electronics factories.

-

Example: In a car assembly plant, the 07KT97F1 uses digital inputs to monitor part presence and analog outputs to adjust robotic welding parameters—ensuring consistent weld quality.

-

-

Water & Wastewater Treatment:

-

Manages pumps, valves, and sensors in water distribution systems.

-

Example: A municipal water treatment plant uses the 07KT97F1 to control chlorine dosing (analog output) based on pH sensor readings (analog input)—complying with environmental regulations.

-

-

Power Generation:

-

Monitors and controls auxiliary systems (e.g., boiler feedwater pumps, cooling fans) in thermal or hydroelectric power plants.

-

Example: In a coal-fired power plant, the 07KT97F1 uses digital outputs to start/stop pumps and analog inputs to monitor temperature—ensuring reliable power generation.

-