Description

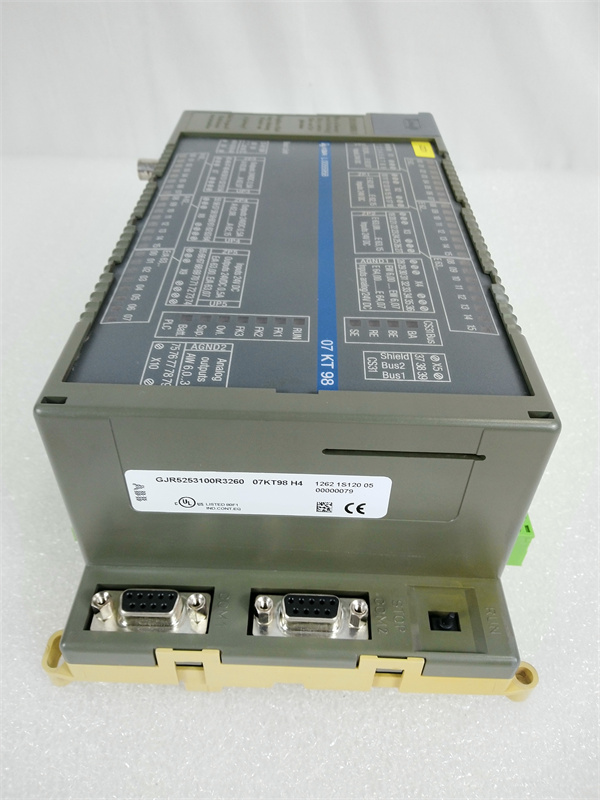

| Parameter name | Parameter value |

| Product model | 07KT98 H4 GJR5253100R3262 |

| Manufacturer | ABB |

| Product category | Temperature monitoring module |

| Measurement range | -50°C to +150°C |

| Input type | 8-channel RTD (Pt100, Pt1000) |

| Accuracy | ±0.1°C (at 0°C reference) |

| Update rate | 100 ms per channel |

| Output signal | 4-20 mA analog (per channel); digital alarm contacts |

| Power supply | 24 VDC ±10% |

| Communication protocol | Modbus RTU, Profibus DP |

| Dimensions (WxHxD) | 120 mm x 80 mm x 60 mm |

| Protection class | IP20 (module); IP40 (terminal block) |

| Operating temperature | -25°C to +70°C |

| Certifications | IEC 61131-2, CE, UL 508 |

ABB 07KT98 H4 GJR5253100R3262

Product introduction

The 07KT98 H4 GJR5253100R3262 is a high-precision temperature monitoring module from ABB, designed to track thermal conditions in industrial processes. As a key component of ABB’s 07KT series, it specializes in converting resistance temperature detector (RTD) signals into actionable data for control systems.

This module processes inputs from 8 independent Pt100/Pt1000 sensors, delivering ±0.1°C accuracy—critical for applications where thermal stability directly impacts product quality or equipment safety. In manufacturing environments, the 07KT98 H4 GJR5253100R3262 acts as a “thermal sentinel,” continuously feeding real-time temperature data to PLCs or DCS systems. Its dual communication protocols (Modbus RTU and Profibus DP) ensure seamless integration into both legacy and modern automation architectures, making it a versatile choice for industries ranging from chemical processing to power generation.

Core advantages and technical highlights

Multi-channel precision: With 8 isolated RTD inputs, the 07KT98 H4 GJR5253100R3262 monitors multiple points without cross-interference. In a plastic extrusion line, this allows simultaneous tracking of barrel zones, die temperature, and cooling water—all with ±0.1°C accuracy. A food processing plant reported a 40% reduction in product waste after replacing analog transmitters with this module, thanks to its stable measurements during pasteurization.

Rapid response time: The 100 ms update rate ensures the 07KT98 H4 GJR5253100R3262 detects temperature spikes before they cause damage. In a turbine control system, this speed enabled the module to trigger cooling adjustments within 200 ms of detecting overheating, preventing a costly shutdown during a critical power grid event.

Flexible integration: Supporting both Modbus RTU and Profibus DP, the 07KT98 H4 GJR5253100R3262 adapts to diverse network setups. A pharmaceutical facility used its Modbus interface to connect with a legacy SCADA system while integrating Profibus for real-time communication with a new MES—eliminating the need for protocol converters and reducing installation time by 30%.

Robust environmental tolerance: Operating from -25°C to +70°C, the 07KT98 H4 GJR5253100R3262 thrives in harsh environments. A mining operation installed it in a dust-prone motor control center, where it maintained calibration for 3 years without maintenance—outperforming competitor modules that required annual servicing.

Typical application scenarios

Chemical reactors: In batch chemical processing, the 07KT98 H4 GJR5253100R3262 monitors reactor wall temperatures at 8 critical points. During exothermic reactions, its rapid update rate ensures the DCS receives temperature spikes in time to adjust cooling water flow, preventing thermal runaway. A specialty chemical plant reduced batch rejection rates by 25% after implementing this module to maintain ±0.5°C control over reaction temperatures.

Industrial ovens: In a metal heat-treating facility, the 07KT98 H4 GJR5253100R3262 tracks zone temperatures in a 12-meter annealing oven. Its 8 channels map to different heating zones, allowing precise profiling of the 500°C to 1000°C ramp cycles. The module’s alarm contacts trigger immediate shutdowns if temperatures exceed safe thresholds, protecting expensive alloys from thermal damage.

Power transformers: Utility substations use the 07KT98 H4 GJR5253100R3262 to monitor winding and oil temperatures in power transformers. By aggregating data from 8 RTDs embedded in the transformer core, it detects hot spots that signal insulation degradation. A regional utility credits the module with reducing unplanned outages by 40% through early fault detection.

ABB 07KT98 H4 GJR5253100R3262

Related model recommendations

07KT97 H3 GJR5253100R3261: 4-channel variant of the 07KT98 H4 GJR5253100R3262, ideal for smaller systems like packaging machines with fewer thermal points to monitor.

07KT99 H5 GJR5253100R3263: 16-channel upgrade with extended -100°C to +200°C range, suitable for large-scale refineries or industrial freezers.

AI890 3BSE032449R1: ABB’s analog input module, pairs with 07KT98 H4 GJR5253100R3262 to expand system I/O for complex thermal networks.

TC800 3BSE013239R1: Thermocouple-compatible module, complementary to the RTD-focused 07KT98 in mixed-sensor environments.

PM864K01: ABB PLC controller that integrates seamlessly with 07KT98 H4 GJR5253100R3262 for localized temperature control logic.

HMI600 3BSE010780R1: Touchscreen HMI displaying real-time data from the 07KT98, enabling operators to set temperature thresholds locally.

07KT98-CAL: Calibration kit for 07KT98 H4 GJR5253100R3262, including precision resistors and software for on-site verification.

Installation, commissioning and maintenance instructions

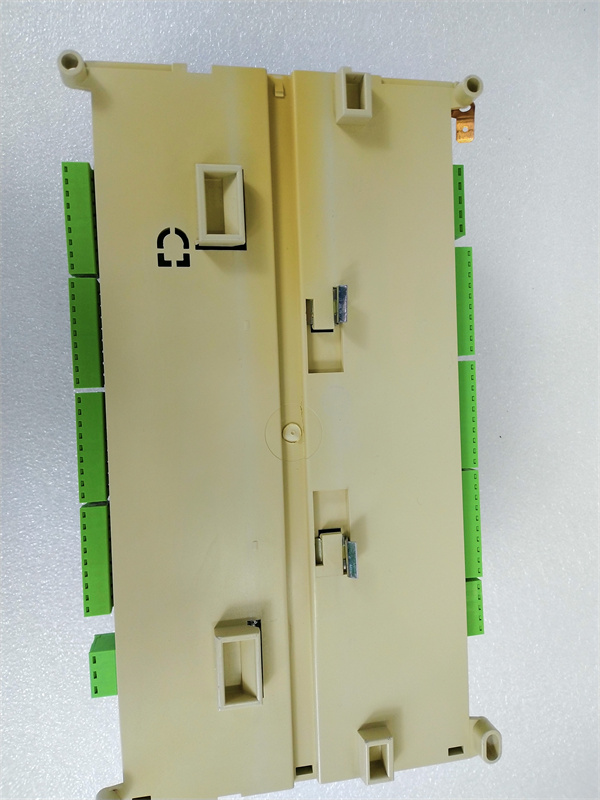

Installation preparation: Mount 07KT98 H4 GJR5253100R3262 on a 35mm DIN rail in a control cabinet, ensuring 50mm clearance for ventilation. Use shielded twisted-pair cables (0.5mm²) for RTD connections, grounding shields at both ends to minimize noise. Terminate sensors using the module’s spring-clamp terminals, torquing to 0.5 Nm. Verify insulation resistance (>100 MΩ at 500 VDC) between RTD inputs and power supply before energization.

Maintenance suggestions: Inspect quarterly for loose terminals and dust buildup—clean with compressed air. Annually calibrate using ABB’s 07KT98-CAL kit, verifying accuracy at 0°C, 50°C, and 100°C references. Replace terminal block fuses (500mA slow-blow) if overcurrent events occur. For drift exceeding ±0.3°C, update firmware via ABB’s Control Builder software. Store spare RTD probes (ABB part 3HAC045678-001) to minimize downtime during sensor failures.

Service and guarantee commitment

ABB backs the 07KT98 H4 GJR5253100R3262 with a 3-year warranty covering manufacturing defects. During this period, ABB provides free replacement of faulty modules and 24/7 technical support via its global network of thermal control specialists (average response <2 hours for critical issues).

Customers gain lifetime access to calibration guides, firmware updates, and application notes through ABB’s Digital Services Portal. Optional services include on-site commissioning with ISO 17025-accredited calibration and operator training. ABB guarantees spare parts availability for 10 years post-production, ensuring long-term reliability in critical thermal monitoring applications. This commitment underscores confidence in the module’s precision and dedication to minimizing process interruptions.