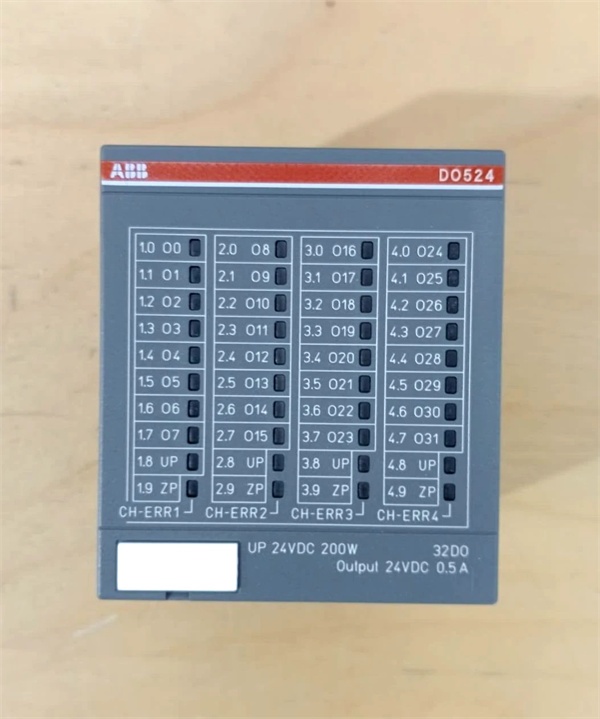

Description

Product Overview

Technical Specifications

-

Input Voltage: 24VDC (nominal), with a tolerance of ±15% (19.2VDC to 27.6VDC) to accommodate voltage fluctuations in industrial settings. -

Input Channels: 16 independent digital input channels, supporting both sinking (NPN) and sourcing (PNP) sensor types—eliminating the need for adapter modules and simplifying wiring. -

Communication: Integrated with the S800 backplane bus, enabling direct communication with the S800 controller without external communication interfaces. This reduces system complexity and minimizes installation time. -

Diagnostic Capabilities: Each channel features built-in fault detection, including open circuit (e.g., disconnected sensor), short circuit (e.g., wiring error), and overvoltage (e.g., transient spikes). Faults are indicated via LED lights on the module and reported to the controller for proactive maintenance. -

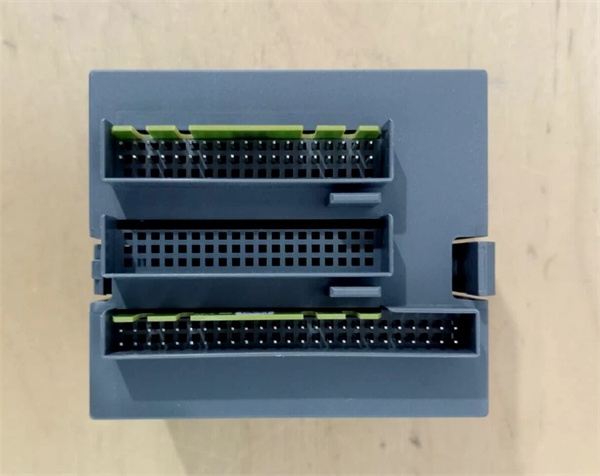

Mechanical Design: DIN-rail mountable (35mm DIN rail) for easy installation in control cabinets. The module has a compact footprint (120mm x 100mm x 25mm) to save space in crowded cabinets. IP20 protection rating prevents accidental contact with live parts, making it suitable for factory floors and machine enclosures. -

Operating Temperature: Rated for -20°C to +60°C, ensuring reliable performance in extreme industrial environments (e.g., cold storage, hot manufacturing plants). -

Power Consumption: Low power draw (≤5W) to minimize energy usage and heat generation in control cabinets. ABB 1SFB527068D7005

Core Features & Customer Value

-

High Channel Density: 16 channels in a compact design reduce the number of modules needed per system, lowering installation and maintenance costs. For example, a machine with 48 digital inputs can be served by just 3 of these modules, instead of 4 modules from a lower-density competitor. -

Sinking/Sourcing Compatibility: Supports both NPN (sinking) and PNP (sourcing) sensors, giving customers flexibility in choosing field devices without rewiring. This is particularly valuable for retrofit projects where existing sensors may use different output types. -

Built-in Diagnostics: Channel-wise fault detection and LED indicators enable quick troubleshooting. For instance, if a sensor cable is disconnected, the corresponding LED will flash red, and the controller will log a fault—reducing downtime from hours to minutes. -

Easy Integration: Integrated with the S800 backplane bus eliminates the need for external communication modules (e.g., RS485 converters), simplifying system design and reducing component count. This also improves system reliability by minimizing potential points of failure. -

Industrial Reliability: Designed for harsh environments (temperature, vibration, electrical noise), the module uses high-quality components (e.g., optocouplers for electrical isolation) to ensure long-term performance. ABB’s global support network provides backup for maintenance and repairs.

Typical Applications

-

Factory Automation: Monitoring sensors on production lines (e.g., proximity sensors for part detection, limit switches for machine positioning). For example, in an automotive assembly line, the module collects signals from sensors that detect car body parts, enabling the controller to adjust robot movements. -

Process Control: Reading signals from valves (e.g., on/off status of solenoid valves in a chemical plant) or pumps (e.g., run status of centrifugal pumps in a water treatment facility). The module’s diagnostic features help detect valve failures early, preventing costly downtime. -

Machine Building: Integrating with machine tools (e.g., CNC mills, presses) to monitor operator inputs (e.g., pushbuttons for start/stop) or safety devices (e.g., emergency stop switches). The module’s high reliability ensures that safety signals are processed quickly, reducing the risk of accidents. -

Material Handling: Tracking conveyor belts (e.g., proximity sensors for package detection) or robotic arms (e.g., limit switches for arm positioning) in warehouses or distribution centers. The module’s compact design allows it to be installed in tight spaces near conveyors.

Core Components

-

Input Circuitry: Optocouplers isolate field devices from the controller, protecting the system from electrical noise and voltage spikes. Each channel has a dedicated optocoupler to ensure isolation. -

Diagnostics Circuitry: Built-in resistors and comparators detect open circuits (e.g., sensor wire break) and short circuits (e.g., sensor output shorted to power). Fault signals are sent to the controller via the backplane bus. -

LED Indicators: Each channel has an LED that lights up green when the input is active (on) and red when a fault is detected. This provides immediate visual feedback for maintenance personnel. -

Mechanical Housing: Made of high-strength plastic (e.g., polycarbonate) to withstand industrial vibrations and impacts. The DIN-rail mounting clips ensure secure installation in control cabinets. ABB 1SFB527068D7005

Installation and Wiring

-

Mounting: The module is mounted on a 35mm DIN rail using built-in clips. No tools are required for mounting, reducing installation time. -

Wiring: Field devices are connected to the module’s terminal blocks. Each channel has two terminals (positive and negative) for 24VDC sensors. The wiring diagram is provided in the module’s user manual, which can be downloaded from ABB’s website. -

Configuration: No software configuration is required for basic operation— the module is automatically detected by the S800 controller during system startup. Advanced configuration (e.g., setting input types) can be done using ABB’s engineering software (e.g., ABB Automation Builder).

Maintenance and Support

-

Preventive Maintenance: Regular inspection of terminal blocks (to check for loose connections) and LED indicators (to detect faults early) is recommended. Cleaning the module’s housing with a dry cloth removes dust and prevents overheating. -

Troubleshooting: Faults are indicated by red LEDs on the module and logged in the S800 controller’s diagnostic buffer. Common faults include open circuits (check sensor wiring), short circuits (check for wiring errors), and overvoltage (install surge protection). -

Support: ABB provides global technical support via its website (abb.com/support), local distributors, and service centers. Spare parts are readily available from ABB’s inventory, minimizing downtime for repairs.

Advantages Over Competitors

-

Higher Channel Density: Compared to competitors (e.g., Siemens SM 321 DI 16x24VDC), the 1SFB527068D7005 offers 16 channels in a similar form factor, reducing the number of modules needed per system. -

Built-in Diagnostics: Many competitors require external diagnostic modules, but the 1SFB527068D7005 has integrated diagnostics, saving cost and space. -

Sinking/Sourcing Compatibility: Not all competitors support both sinking and sourcing sensors— the 1SFB527068D7005’s compatibility gives customers more flexibility. -

ABB Ecosystem Integration: The module integrates seamlessly with other ABB products (e.g., S800 controllers, drives, HMIs), providing a unified solution for industrial automation.