Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 200900-004 |

| Manufacturer | ABB |

| Product category | Heavy-duty terminal block |

| Number of terminals | 4 poles |

| Rated voltage | 600 V AC/DC |

| Rated current | 63 A |

| Wire size range | 10-2 AWG (4-35 mm²) |

| Connection type | Screw clamp (with cage clamp technology) |

| Material | Polyamide 6.6 (UL94 V0 flame rating) |

| Mounting type | DIN rail mount (35 mm TS35) |

| Protection rating | IP20 |

| Temperature range | -40°C to 100°C |

| Torque rating | 4.5 Nm |

| Certifications | UL 1059, IEC 60947-7-1, CE, RoHS |

ABB 200900-004

Product introduction

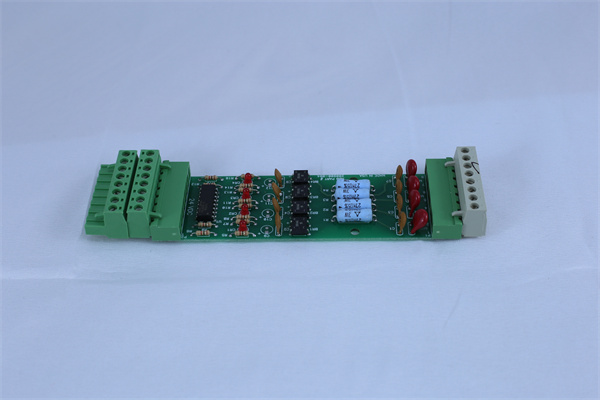

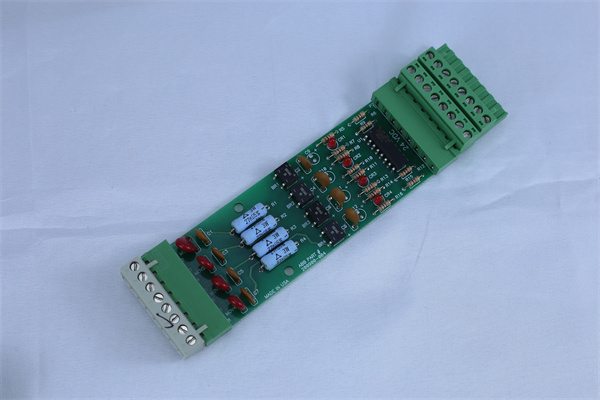

The ABB 200900-004 is a robust heavy-duty terminal block designed to provide secure and reliable electrical connections in industrial environments. As part of ABB’s terminal block portfolio, ABB 200900-004 is engineered to handle high currents and voltages, making it ideal for power distribution applications in machinery, switchgear, and industrial control panels.

ABB 200900-004 features 4 poles with screw clamp connections, utilizing ABB’s cage clamp technology to ensure vibration-resistant wire termination. Its polyamide 6.6 construction offers excellent mechanical strength and flame resistance, while its wide operating temperature range allows deployment in extreme environments. Whether used to connect power cables in motor control centers or distribute power in renewable energy installations, ABB 200900-004 delivers consistent performance, minimizing connection failures and ensuring long-term system reliability.

Core advantages and technical highlights

High current handling capacity: With a 63 A rating and 600 V AC/DC capability, ABB 200900-004 accommodates heavy-duty power connections that standard terminal blocks cannot handle. In a manufacturing plant’s motor control center, this allows the terminal block to safely connect 50 HP motor cables (10 AWG) without overheating, ensuring efficient power transmission and reducing the risk of fire hazards. Its robust design prevents voltage drops even under peak load conditions, maintaining stable operation of critical equipment.

Vibration-resistant connections: ABB 200900-004 incorporates ABB’s cage clamp technology, which uses a spring-loaded cage to secure wires under the screw clamp—eliminating the need for retightening over time. This feature is particularly valuable in mobile equipment (e.g., industrial cranes) or plants with high vibration, where traditional screw terminals might loosen. Testing shows the connections remain secure even after 100,000 vibration cycles (10-500 Hz), reducing maintenance requirements and unplanned downtime.

Wide temperature tolerance: Operating reliably from -40°C to 100°C, ABB 200900-004 performs in extreme environments, from cold storage facilities to high-temperature industrial ovens. Its polyamide 6.6 housing retains mechanical strength at low temperatures and resists deformation under heat, ensuring consistent clamping force across the entire temperature range. In a steel mill’s hot rolling facility, where ambient temperatures often reach 80°C, this stability prevents connection degradation and maintains electrical continuity.

Versatile wire compatibility: ABB 200900-004 accepts wires from 10 AWG (4 mm²) to 2 AWG (35 mm²), eliminating the need for multiple terminal block sizes in mixed-gauge installations. A solar inverter cabinet, for example, can use the same terminal block to connect 6 AWG DC input cables and 2 AWG output cables, simplifying inventory management and reducing installation time by up to 30%.

Typical application scenarios

In a data center’s UPS system, ABB 200900-004 terminal blocks connect the main power feed (600 V AC, 50 A) to distribution panels, ensuring reliable backup power to server racks. Their vibration-resistant design prevents loose connections during generator startup, while their high current rating handles the inrush current from battery banks. The terminal blocks’ flame-resistant housing also enhances fire safety in the densely packed electrical room, complying with data center fire codes.

In a wind turbine’s nacelle, ABB 200900-004 connects the generator output (690 V AC, 60 A) to the power converter. The terminal blocks withstand extreme temperature fluctuations (-30°C to 70°C) and constant vibration from the turbine blades, maintaining secure connections in this harsh environment. Their ability to handle large wire sizes (4 AWG) simplifies the connection of thick, flexible cables used in the nacelle, reducing installation complexity for turbine technicians.

ABB 200900-004

Related model recommendations

ABB 200900-008: An 8-pole variant of ABB 200900-004 for applications requiring more connections in the same footprint.

ABB 200900-002: A 2-pole terminal block with identical ratings to ABB 200900-004, ideal for smaller power circuits.

ABB TB857: A surge protection terminal block that pairs with ABB 200900-004 to shield equipment from voltage transients.

ABB PM633: A PLC whose power supply connections can be terminated using ABB 200900-004 in control panels.

ABB DI651: A digital input module that uses auxiliary ABB 200900-004 blocks for power distribution in I/O racks.

ABB 1SNA668010R1000: A DIN rail end clamp that secures ABB 200900-004 terminal blocks in place, preventing movement.

Installation, commissioning and maintenance instructions

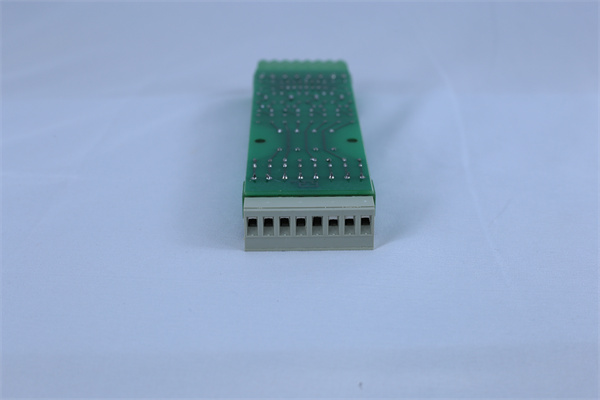

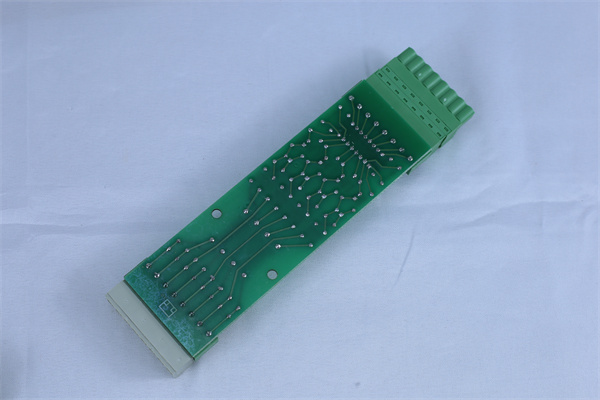

Installation preparation: Mount ABB 200900-004 on a 35 mm TS35 DIN rail, ensuring the rail is securely fastened to the panel. Use end clamps to prevent lateral movement of the terminal block. Strip wires to 12 mm (0.47 inches) and insert into the clamp opening—ensure no stranded wires are protruding. Tighten the screw clamp to 4.5 Nm using a torque screwdriver to achieve proper clamping force. For stranded wires, use ferrules to prevent fraying. Ensure the installation environment is free from conductive dust and moisture. Disconnect power before installation to avoid electrical hazards.

Maintenance suggestions: Inspect ABB 200900-004 annually for loose connections, corrosion, or signs of overheating (discoloration). Re-torque screws to 4.5 Nm if necessary—do not exceed the rated torque, as this may damage the clamp. Clean terminals with a dry cloth; avoid using liquids or abrasive materials. Check for wire damage near the connection points, replacing any frayed or oxidized wires. In high-vibration environments, inspect connections quarterly to ensure the cage clamp technology maintains proper contact. Replace the terminal block if the housing is cracked or the clamp mechanism fails to secure wires.

Service and guarantee commitment

ABB 200900-004 is backed by a 10-year warranty from installation, covering manufacturing defects and ensuring compliance with current standards for current carrying capacity and insulation. ABB’s technical support team provides response within 8 hours for standard inquiries, with application guidance available during business hours to assist with installation questions.

The warranty includes access to technical specifications and installation guides. Extended service contracts offer annual inspections of terminal block installations, ensuring proper torque and connection integrity. ABB’s commitment to quality underscores confidence in ABB 200900-004 as a durable solution for heavy-duty electrical connections, designed to perform reliably throughout its 20-year service life.