Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 206-00212 |

| Manufacturer | ABB |

| Product category | Servo motor encoder (industrial motion control) |

| Encoder type | Absolute rotary encoder |

| Resolution | 17-bit (131072 positions) |

| Output signals | SSI (Synchronous Serial Interface) |

| Operating voltage | 5 VDC ±5% |

| Maximum rotational speed | 6000 RPM |

| Shaft diameter | 6mm |

| Protection rating | IP65 |

| Operating temperature | -40°C to 85°C |

| Storage temperature | -55°C to 100°C |

| Vibration resistance | 100g (11ms), 10g (10-2000Hz) |

| Shock resistance | 1000g (6ms) |

| Weight | 0.28kg |

| Certifications | CE, RoHS, UL |

| Mounting type | Flange mount (50mm diameter) |

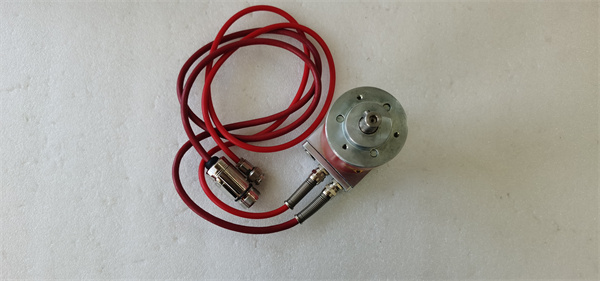

ABB 206-00212

Product introduction

The ABB 206-00212 is a high-precision absolute rotary encoder designed for seamless integration with ABB servo motors and motion control systems, serving as a critical feedback device in industrial automation. This encoder provides real-time position, speed, and direction data to the motor controller, enabling precise motion control in applications requiring accuracy and repeatability.

As an absolute encoder, the ABB 206-00212 retains position information even when power is lost, eliminating the need for homing sequences during system startup—a key advantage in automated production lines where downtime must be minimized. Its 17-bit resolution ensures exceptional positioning accuracy, making it suitable for high-precision tasks such as robotic assembly, CNC machining, and packaging machinery.

Within motion control systems, the ABB 206-00212 acts as the “eyes” of the servo motor, continuously feeding data to the controller to adjust torque and speed. This closed-loop feedback loop ensures the motor maintains exact positions and trajectories, even under varying loads or external disturbances. Its rugged design and industrial-grade protection make it reliable in harsh factory environments, where dust, vibration, and temperature fluctuations are common.

Core advantages and technical highlights

Absolute position retention: Unlike incremental encoders, the ABB 206-00212 stores position data internally, preserving it during power cycles. This eliminates the need for time-consuming homing procedures when systems restart, reducing downtime in critical applications like semiconductor wafer handling—where even seconds of delay impact production yields. The encoder’s non-volatile memory ensures position accuracy is maintained indefinitely without power.

High-resolution feedback: With 17-bit resolution (131072 distinct positions per revolution), the ABB 206-00212 delivers precise position data, enabling servo motors to achieve sub-micron positioning in applications such as PCB drilling or laser cutting. This level of detail ensures consistent product quality, as even minor positional errors are corrected in real time by the motion controller.

Robust environmental tolerance: Rated IP65, the ABB 206-00212 withstands dust ingress and low-pressure water jets, making it suitable for washdown environments in food processing or pharmaceutical packaging. Its wide operating temperature range (-40°C to 85°C) allows deployment in cold storage facilities or high-heat industrial zones like foundries, while its vibration and shock resistance ensure reliability near heavy machinery.

SSI interface efficiency: The ABB 206-00212 uses a Synchronous Serial Interface (SSI) to transmit data, enabling high-speed communication (up to 1.5 Mbps) with minimal latency. This ensures position updates are delivered to the controller in real time, critical for dynamic applications like robotic pick-and-place systems where rapid changes in speed and direction demand instant feedback.

Typical application scenarios

In automotive assembly robots, the ABB 206-00212 provides precise position feedback for servo motors controlling welding torches. Its 17-bit resolution ensures the torch maintains exact distances from the workpiece, ensuring consistent weld quality across thousands of units. The absolute positioning feature allows the robot to resume operations immediately after a power interruption, avoiding costly rework or production delays.

Within CNC machining centers, the ABB 206-00212 integrates with servo motors driving linear axes and spindles. It delivers real-time position data to the machine controller, enabling tight tolerance machining (±0.001mm) for precision components like engine valves. The encoder’s vibration resistance ensures accuracy even during high-speed cutting operations, where spindle speeds exceed 10,000 RPM.

In packaging machinery, the ABB 206-00212 synchronizes servo motors controlling film feed and sealing mechanisms. Its high-speed SSI interface ensures the controller adjusts for material stretch or slippage, maintaining precise seal positions on packages. The IP65 rating allows safe operation in washdown cycles, common in food packaging lines to meet hygiene standards.

ABB 206-00212

Related model recommendations

ABB 206-00213: A 16-bit variant of the ABB 206-00212 with lower resolution, suitable for cost-sensitive applications where extreme precision is not required.

ABB M3LP servo motor: A high-torque servo motor paired with the ABB 206-00212 for complete motion control solutions in industrial robots.

ABB ACS880-M04 drive: A servo drive that processes feedback from the ABB 206-00212 to regulate motor performance.

ABB 3HAC031683-001: A encoder cable specifically designed for the ABB 206-00212, ensuring noise-free signal transmission in industrial environments.

ABB DSQC 652: A robot control module that integrates data from the ABB 206-00212 for coordinated multi-axis motion in robotic systems.

ABB 800xA Motion Control: Software that visualizes and optimizes performance data from the ABB 206-00212 and connected servo systems.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB 206-00212, ensure the motor shaft is clean and free of burrs. Verify the mounting flange (50mm diameter) aligns with the motor’s encoder port, and use a torque wrench to secure it to 0.5 Nm to avoid damaging internal components. Required tools include a 6mm Allen key, shaft alignment tool, and multimeter. Use the recommended shielded cable (0.3mm²) for SSI connections, with the shield grounded at both ends to prevent EMI interference.

Maintenance suggestions: Inspect the ABB 206-00212 semi-annually for loose connections or debris around the shaft seal. Clean the exterior with a dry cloth—avoid liquids, even though it’s IP65-rated. Check cable integrity for cuts or abrasions, as damaged insulation can introduce noise. Test signal output annually using an encoder tester to verify resolution and data consistency. If the encoder fails, replace it with an ABB-approved unit to maintain motor performance and warranty coverage. Avoid disassembling the encoder, as this will void certifications and damage precision components.

Service and guarantee commitment

The ABB 206-00212 is backed by a 24-month warranty from the date of installation, covering manufacturing defects and ensuring compliance with published performance specifications. ABB guarantees that any faulty unit will be replaced within 48 hours for critical production lines, minimizing downtime in motion control systems.

Technical support includes access to ABB’s global team of motion control specialists, available for assistance with installation, calibration, and troubleshooting. Online resources include detailed wiring diagrams, signal timing charts, and compatibility guides for integrating the ABB 206-00212 with ABB servo systems. Customers can opt for extended service contracts offering annual performance testing, preventive maintenance, and on-site support, ensuring the encoder delivers reliable feedback throughout its 10-year design lifespan.