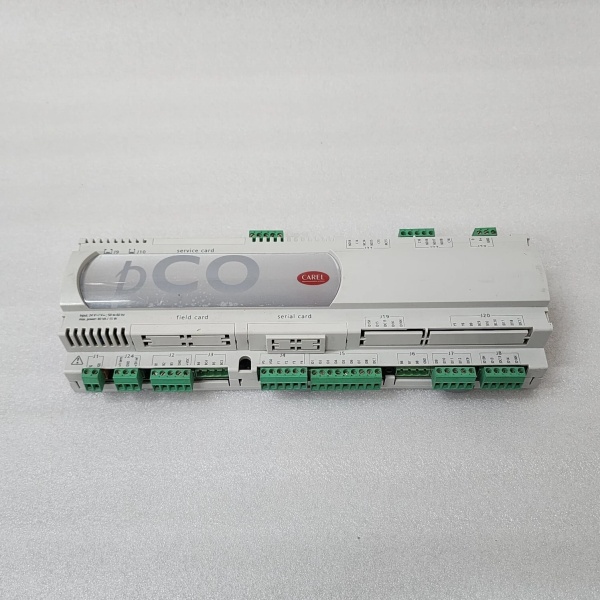

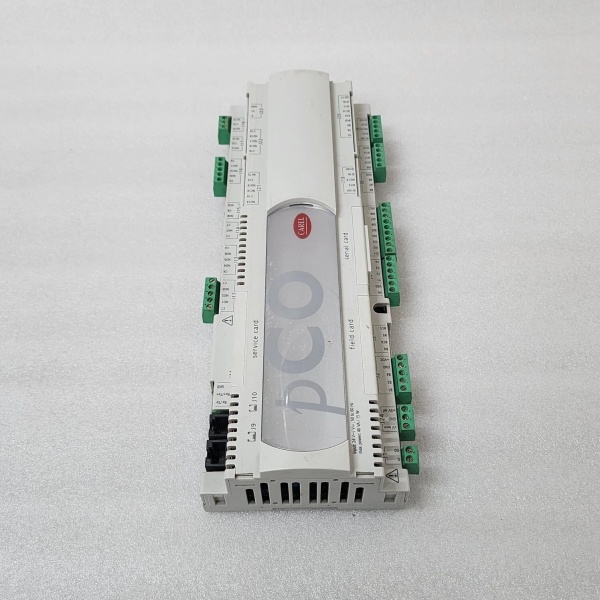

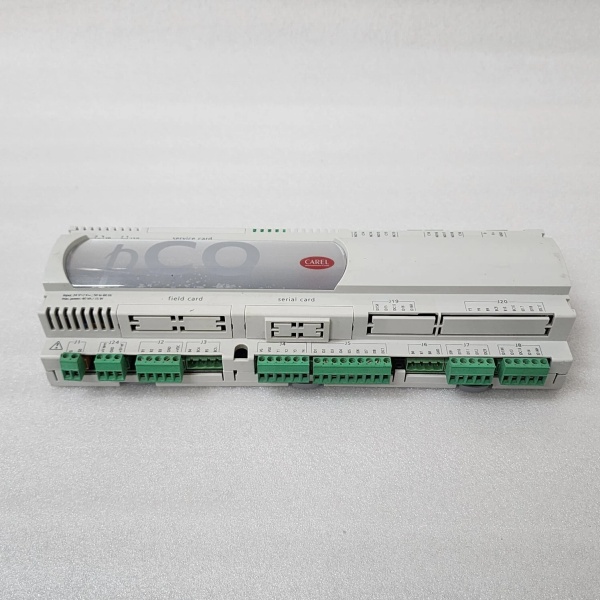

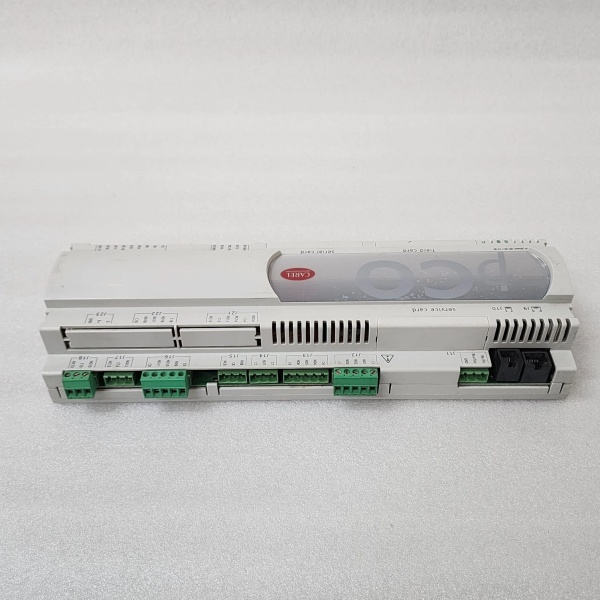

Description

ABB PCO011 3BDZ000371R1

-

Model Number: 3BDZ000371R1 PCO011 -

Manufacturer: ABB -

Product Type: Programmable Controller Module -

Processor: 32-bit RISC -

Memory: 8 MB RAM, 4 MB Flash -

I/O Capacity: Up to 256 I/O points (expandable) -

Communication Ports: 2x Ethernet, 1x RS-232, 1x RS-485 -

Protocol Support: Modbus TCP, Modbus RTU, PROFIBUS DP -

Power Supply: 24 V DC -

Operating Temperature: -20°C to +60°C -

Storage Temperature: -40°C to +85°C -

Humidity: 5% to 95% non-condensing -

Dimensions: 100 mm x 150 mm x 60 mm -

Weight: 0.5 kg

ABB PCO011 3BDZ000371R1