Description

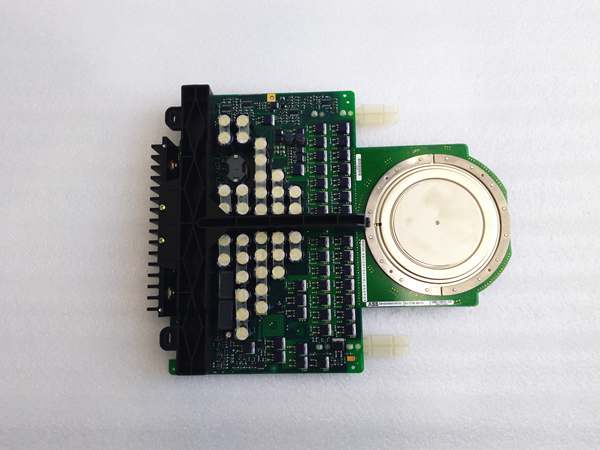

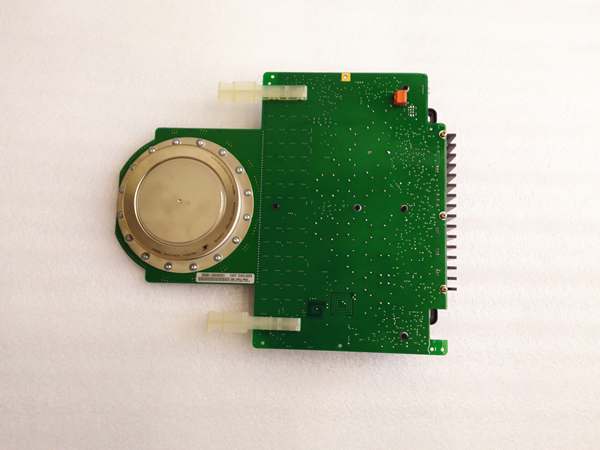

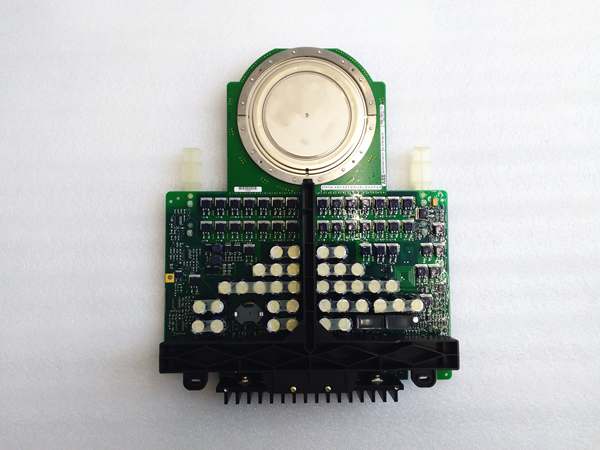

ABB 3BHB013088R0001 GVC750BE101

-

Model Number: 3BHB013088R0001 GVC750BE101 -

Manufacturer: ABB -

Product Type: VFD Control Module -

Processor: 32-bit PowerPC 405, 266 MHz -

Memory: 256MB RAM, 512MB Flash (firmware/user parameters) -

Control Algorithm: Flux-vector control, Direct Torque Control (DTC) -

Communication Protocols: Profibus DP (up to 12 Mbps), Modbus TCP, Ethernet IP, CANopen (optional) -

Input Signals: Analog (4-20mA, 0-10V), Digital (24V DC, dry contact), Encoder (TTL/HTL, up to 100kHz) -

Output Signals: PWM (to inverter stage), Relay (fault, ready), Analog (0-10V speed feedback) -

Operating Temperature: -25°C to +60°C -

Power Supply: 24V DC (from GVC750 drive internal supply, 18-32V DC range) -

Power Consumption: 8W (typical) -

Dimensions: 180mm x 120mm x 45mm (width x height x depth, fits GVC750 control compartment) -

Weight: 0.5kg -

Certifications: CE, UL, cULus, RoHS, ISO 13849 (PLd, for safety functions)

ABB 3BHB013088R0001 GVC750BE101