Description

| Parameter name | Parameter value |

| Product model | 3BHB045647R0001 GVC736CE101 |

| Manufacturer | ABB |

| Product category | Industrial communication interface module |

| Communication protocols | Ethernet/IP, Modbus TCP/IP, Profinet |

| Data transfer rate | Up to 1 Gbps |

| Supported controllers | AC800M series (including 3BSE053240R1 PM891) |

| Operating voltage | 24V DC ±10% |

| Power consumption | 8W typical, 10W maximum |

| Operating temperature | -25°C to +60°C |

| Dimensions (W×H×D) | 80mm × 120mm × 150mm |

| Protection rating | IP20 (when mounted in cabinet) |

| Certifications | CE, UL 508, IEC 61131-2 |

| Mounting type | DIN rail (35mm) |

| Number of Ethernet ports | 2×RJ45 (gigabit) |

| Redundancy support | Media redundancy protocol (MRP) |

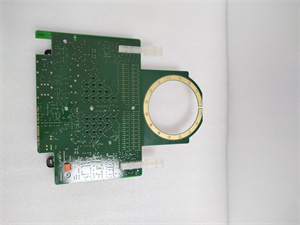

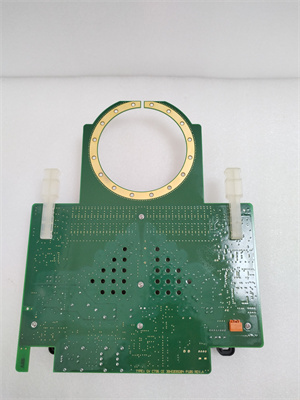

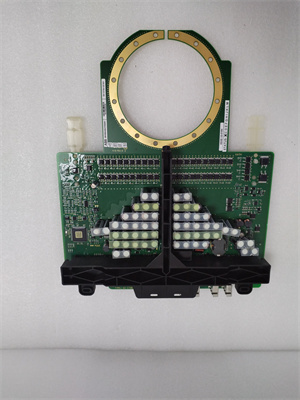

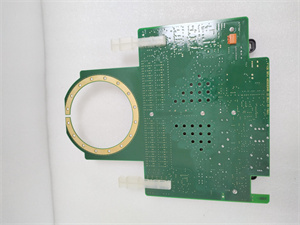

ABB 3BHB045647R0001 GVC736CE101

Product introduction

The ABB 3BHB045647R0001 GVC736CE101 is a high-performance industrial communication interface module designed to facilitate seamless data exchange between ABB’s AC800M distributed control systems (including the 3BSE053240R1 PM891 CPU module) and other automation components. As a critical connectivity hub, this module bridges different industrial networks, enabling interoperability between controllers, I/O devices, and supervisory systems.

ABB 3BHB045647R0001 GVC736CE101 supports multiple industry-standard protocols—Ethernet/IP, Modbus TCP/IP, and Profinet—making it a versatile solution for both new installations and legacy system upgrades. Its gigabit Ethernet ports ensure high-speed data transmission, essential for real-time control applications where latency can impact process efficiency. When paired with the 3BSE053240R1 PM891, it extends the controller’s communication reach, allowing integration with sensors like the PFCL201C 20KN load cell and third-party equipment such as variable frequency drives or SCADA systems.

Core advantages and technical highlights

Multi-protocol flexibility

The 3BHB045647R0001 GVC736CE101 eliminates the need for multiple single-protocol modules by supporting Ethernet/IP, Modbus TCP/IP, and Profinet in a single device. In a mixed-automation environment—say, a automotive plant using ABB robots, Siemens PLCs, and Rockwell HMI panels—this module acts as a translator, enabling the 3BSE053240R1 PM891 controller to communicate with all components. This reduces cabinet space requirements and simplifies system architecture, lowering both initial and long-term maintenance costs.

High-speed, low-latency performance

With gigabit Ethernet ports and optimized protocol handling, 3BHB045647R0001 GVC736CE101 ensures data transfer latency of less than 1ms—critical for time-sensitive applications like synchronized motion control in manufacturing lines. In a packaging plant, for example, it enables the 3BSE053240R1 PM891 to adjust conveyor speeds in real time based on product position data from vision systems, ensuring precise alignment during labeling and sealing processes.

Redundant network support

Equipped with media redundancy protocol (MRP) support, 3BHB045647R0001 GVC736CE101 enhances network reliability by automatically switching to backup communication paths in case of cable or switch failures. In a water treatment plant, this redundancy ensures continuous data flow between the 3BSE053240R1 PM891 and pump control systems, preventing process disruptions that could lead to water quality issues or equipment damage.

ABB 3BHB045647R0001 GVC736CE101

Typical application scenarios

Industrial IoT (IIoT) gateway

In smart factory implementations, 3BHB045647R0001 GVC736CE101 serves as an IIoT gateway, aggregating data from the 3BSE053240R1 PM891 controller, PFCL201C 20KN load cells, and other sensors, then transmitting it to cloud-based analytics platforms. For a food processing plant, this allows remote monitoring of mixing tank weights, conveyor speeds, and temperature profiles, enabling predictive maintenance and process optimization. The module’s protocol conversion capabilities ensure compatibility with cloud services regardless of their native communication standards.

Legacy system modernization

When upgrading older industrial systems, 3BHB045647R0001 GVC736CE101 connects legacy equipment (e.g., 20-year-old motors with Modbus RTU interfaces) to the 3BSE053240R1 PM891 controller. In a steel mill, for example, it converts data from aging temperature controllers into Ethernet/IP signals, allowing the modern DCS to monitor and adjust furnace conditions. This avoids the cost of replacing fully functional equipment while gaining the benefits of centralized control and data logging.

Critical infrastructure monitoring

In power distribution substations, 3BHB045647R0001 GVC736CE101 facilitates communication between the 3BSE053240R1 PM891 and protection relays, circuit breakers, and SCADA systems. It ensures real-time transmission of fault data, enabling rapid response to grid disturbances. The module’s robust design withstands the electromagnetic interference common in substation environments, ensuring reliable operation even during electrical transients.

Related model recommendations

- 3BSE053240R1 PM891: AC800M CPU module, the primary controller paired with 3BHB045647R0001 GVC736CE101for data processing and control.

- 3BHB009884R5211: Digital I/O module, whose status data is transmitted via 3BHB045647R0001 GVC736CE101to the supervisory system.

- PFCL201C 20KN: ABB load cell, whose force measurements are relayed through 3BHB045647R0001 GVC736CE101to the 3BSE053240R1 PM891.

- CI854A 3BSE013232R1: Profibus DP module, works with 3BHB045647R0001 GVC736CE101to extend the 3BSE053240R1 PM891’s connectivity to Profibus devices.

- 3BSE022496R1 TB855: Terminal block, provides secure wiring connections between field devices and 3BHB045647R0001 GVC736CE101.

- 3BSE018106R1 PM864K01: Mid-range CPU module, compatible with 3BHB045647R0001 GVC736CE101for smaller-scale systems.

- 3BSE008549R1 PS860: Redundant power supply, ensures stable 24V DC to 3BHB045647R0001 GVC736CE101and associated modules.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 3BHB045647R0001 GVC736CE101, ensure the control cabinet is free from excessive dust and moisture, with ambient temperatures between -25°C and +60°C. Mount the module on a 35mm DIN rail using M3 screws (torque 0.5Nm), leaving at least 20mm of clearance on all sides for cooling. Use ESD-safe handling procedures to prevent electrostatic damage. Connect to the 3BSE053240R1 PM891 via the backplane or dedicated communication cable, then attach Ethernet cables (Cat6 for gigabit speeds) to the RJ45 ports, ensuring proper strain relief. Configure initial network settings (IP address, subnet mask) using ABB’s Communication Configurator tool before integrating with devices like the PFCL201C 20KN.

Maintenance suggestions: Inspect 3BHB045647R0001 GVC736CE101 quarterly for loose connections or dust buildup, cleaning with compressed air (max 50psi) if needed. Monitor network traffic and error rates via the module’s web interface; excessive errors may indicate cable damage or interference. Update firmware annually to ensure compatibility with the latest versions of the 3BSE053240R1 PM891 controller software. In case of communication failures with sensors like the PFCL201C 20KN, first check cable continuity and protocol settings before replacing the module. Store spare units in anti-static packaging in a dry environment (10-30°C).

Service and guarantee commitment

ABB provides a 3-year warranty for 3BHB045647R0001 GVC736CE101, covering defects in materials and workmanship under normal operating conditions. Our technical support team offers 24/7 assistance for configuration, protocol troubleshooting, and integration with the 3BSE053240R1 PM891 and other components, with response times within 4 hours for critical issues.

Factory repair services for 3BHB045647R0001 GVC736CE101 use genuine parts and include full functionality testing, with a 5-business-day turnaround. For urgent replacements, we offer next-business-day delivery in major industrial regions. ABB also provides training on module setup, including best practices for integrating with devices like the PFCL201C 20KN, ensuring customers maximize system reliability and performance.