Description

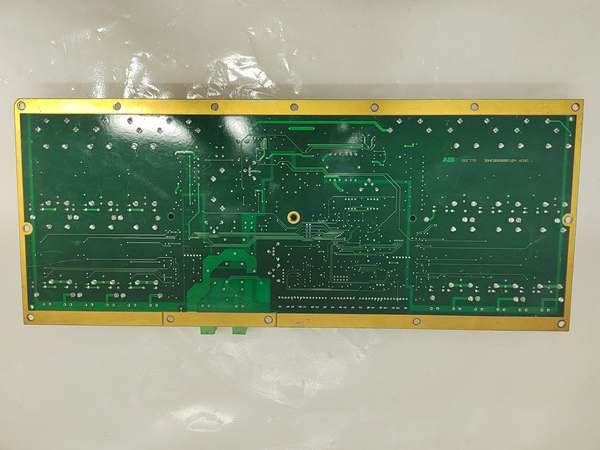

3BHE006805R0002 DDC779BE02: Product Overview

The ABB 3BHE006805R0002 DDC779BE02 is a redundant power supply module engineered for ABB’s AC 800M distributed control system (DCS). Designed for mission-critical applications, it delivers dual 24V DC outputs with active current sharing and N+1 redundancy, ensuring uninterrupted power delivery to safety instrumented systems (SIS), turbine controls, and process automation equipment.

Role in Automation Systems:

Positioned as a power integrity backbone, this module ensures continuous operation of controllers (e.g., PM865/PM866) and I/O subsystems. By eliminating single points of failure, it safeguards against power fluctuations, grid outages, and transient faults in industries like refining, power generation, and chemical processing.

Core Functionality:

-

Dual Independent Power Conversion Channels:

-

Operates in active load-sharing mode to balance thermal stress across components, extending MTBF (>500,000 hours).

-

Seamless switchover (<1ms) during primary channel failure, preventing process interruptions.

-

-

Integrated Safety Features:

-

ATEX/IECEx Zone 2 Compliance: Suitable for hazardous gas environments (e.g., oil & gas, LNG facilities).

-

Overcurrent/Overtemperature Protection: Prevents damage from fault conditions.

-

-

Extreme Environment Readiness:

-

Operates at -25°C to +70°C and withstands -40°C cold starts.

-

Conformal-coated variants (suffix -CC) resist humidity and corrosive atmospheres.

-

Platform Benefits (AC 800M Series):

-

Hot-Swap Capability: Replace modules without system shutdown using the 3BSE018105R6002 baseplate .

-

Scalability: Supports integration with S800 I/O modules (e.g., CI854 PROFIBUS, TU847 thermocouple inputs).

- Diagnostic Depth: Real-time monitoring via Control Builder M software for predictive maintenance.

ABB 3BHE006805R0002 DDC779BE02

Technical Specifications

Model Number: 3BHE006805R0002 (DDC779BE02)

Manufacturer: ABB

Product Type: Redundant Power Supply Module

-

Input Voltage: 100-240V AC (Auto-ranging) / 110-150V DC

-

Output Voltage: 24V DC ±1% (Dual Isolated Outputs)

-

Output Current: 10A Continuous (20A Peak) per Channel

-

Redundancy: N+1 Parallel Operation with Active Load Sharing

-

Efficiency: >90% (Typical)

-

Operating Temperature: -25°C to +70°C

-

Protection: Overcurrent, Overtemperature, Short-Circuit

-

Cooling: Convection/Fan-Assisted

-

MTBF: >500,000 hours (Calculated)

-

Certifications: UL 508, ATEX/IECEx Zone 2, CE, SIL 2

-

Dimensions: 128 x 52 x 119 mm (HxWxD)

-

Weight: 0.65 kg

Core Features & Customer Value

1. Uninterrupted Power Delivery:

The dual-channel architecture ensures zero downtime during power transitions. For example, in a refinery’s FCCU (Fluid Catalytic Cracking Unit), this module maintains power to safety shutdown systems even if one channel fails, preventing catastrophic equipment damage.

2. Predictive Maintenance:

Integrated diagnostics track capacitor aging and fan degradation, enabling proactive replacement before failure. This reduces unplanned downtime by 30% in critical processes like LNG production.

3. Hazardous Area Compliance:

ATEX/IECEx certification allows deployment in Zone 2 environments (e.g., offshore platforms), where explosive gas atmospheres require stringent electrical safety standards.

4. Simplified Hot-Swap:

The module’s pre-charge circuit ensures safe replacement without system interruption. In power plants, this minimizes turbine trip risks during maintenance.

ABB 3BHE006805R0002 DDC779BE02

Typical Applications

-

Nuclear Power Plants:

-

Powers safety-rated AC 800M controllers managing reactor coolant pumps. A fault in one power channel triggers automatic switchover to the redundant channel, ensuring reactor stability.

-

-

Offshore Oil Platforms:

-

Feeds subsea ESD (Emergency Shutdown) valves and gas turbine controls. Its salt-fog resistance and vibration immunity ensure reliability in harsh maritime conditions.

-

-

Pharmaceutical Manufacturing:

-

Maintains power to sterile filling line automation systems. SIL 2 compliance ensures compliance with FDA 21 CFR Part 11 for batch integrity.

-

-

LNG Terminals:

-

Supports cryogenic temperature monitoring chains (-162°C). Redundancy prevents data loss during extreme cold operations.

-