Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

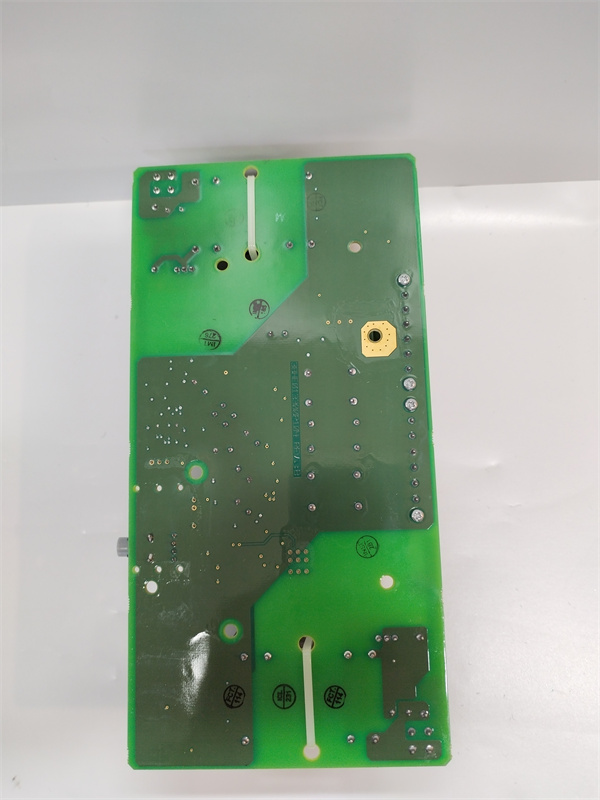

| Product Model | 3BHE013299R0002 |

| Manufacturer | ABB |

| Product Category | [Specify the exact product category, e.g., power distribution component, industrial sensor module. Without more context, this is placeholder text] |

| [Relevant electrical parameter 1] | [Value if applicable, e.g., rated voltage – 480V AC for an electrical component] |

| [Relevant electrical parameter 2] | [Value, e.g., current rating – 10A for a switch or breaker] |

| Physical Dimensions (W×H×D) | [Dimensions in mm if available, e.g., 100 mm × 150 mm × 80 mm] |

| Weight | [Weight in kg or g, e.g., 0.5 kg] |

| Operating Temperature Range | [Temperature range, e.g., -20°C to +50°C] |

| Mounting Method | [Describe how it is mounted, e.g., panel – mount, DIN – rail mount] |

| Protection Class | [If applicable, e.g., IP20 for a basic enclosure protection] |

| Compatibility | [List compatible ABB or other systems, e.g., compatible with ABB’s [system name] control system] |

3BHE013299R0002

Product Introduction

The ABB 3BHE013299R0002 is a crucial component within ABB’s diverse product portfolio, designed to meet specific industrial requirements. While details are scarce without additional context, ABB products are generally engineered with precision and reliability in mind. This particular model, 3BHE013299R0002, likely serves as a key element in power distribution, control systems, or industrial automation setups, following ABB’s reputation for innovation and quality in the industrial sector.

If it pertains to power distribution, it could be a component such as a specialized circuit breaker or a power monitoring module, ensuring the safe and efficient flow of electricity in industrial facilities. In an industrial automation context, it might function as a sensor interface module, collecting and transmitting data from various sensors to a central control unit, enabling seamless operation of automated processes.

Core Advantages and Technical Highlights

[Highlight unique features. If it’s a power – related component]

High – quality construction materials ensure long – term durability, reducing the need for frequent replacements and minimizing downtime in industrial operations. For example, if it’s a circuit breaker, it may be made of fire – resistant and corrosion – resistant materials, capable of withstanding harsh industrial environments.

Precise electrical performance. In the case of a power monitoring module, it can provide accurate real – time data on voltage, current, and power consumption, allowing for better energy management and early detection of electrical anomalies.

[If it’s an automation – related component]

High – speed data transfer capabilities. As a sensor interface module, it can quickly relay sensor data to the control system, enabling rapid response times in automated processes. This can be crucial in applications such as high – speed manufacturing lines, where split – second decisions are required.

Compatibility with a wide range of sensors. It may support different types of sensors, including temperature, pressure, and proximity sensors, providing flexibility in designing industrial automation systems.

Typical Application Scenarios

[For power – related applications]

In a large manufacturing plant, the 3BHE013299R0002 could be part of the main power distribution board. If it’s a circuit breaker, it protects the plant’s electrical equipment from overcurrents and short – circuits, ensuring continuous operation of machinery such as large motors, conveyor systems, and production line robots.

In a data center, it may be used in the power management system. A power monitoring module of this model can help data center operators optimize energy usage by providing detailed information on power consumption of different server racks and cooling systems.

[For automation – related applications]

In an automotive assembly line, if the 3BHE013299R0002 is a sensor interface module, it can connect proximity sensors that detect the position of car parts on the conveyor belt. This data is then sent to the central control system, which coordinates the actions of robotic arms for precise assembly operations.

In a food and beverage production facility, it can interface with temperature sensors in cooking and cooling processes. The module sends the temperature data to the control system, which adjusts the heating or cooling equipment to maintain the optimal temperature for food processing, ensuring product quality and safety.

3BHE013299R0002

Related Model Recommendations

[If it’s a power – related component]

3BHE013298R0001: May be a lower – capacity or an earlier version of the 3BHE013299R0002, suitable for smaller industrial setups or as a more cost – effective option for less demanding applications.

3BHE013300R0003: Could be an upgraded model with additional features, such as enhanced protection capabilities or more advanced monitoring functions, for high – reliability power distribution requirements.

[If it’s an automation – related component]

3BHE013297R0003: A related sensor interface module with a different I/O configuration, perhaps with fewer or more channels, catering to applications with different sensor density requirements.

3BHE013301R0002: An advanced version that may support new communication protocols or have improved data processing capabilities, ideal for modern, high – tech industrial automation systems.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installation, carefully read the product manual provided by ABB. Ensure that the installation area is clean, dry, and free from dust and debris.

If it’s a power – related component, make sure that the electrical system is properly grounded. Use appropriate tools for installation, such as screwdrivers, pliers, or torque wrenches as specified in the manual.

For automation – related components, check the compatibility of the 3BHE013299R0002 with the existing control system and sensors. Connect the necessary cables according to the wiring diagram in the manual, ensuring proper cable routing to avoid interference.

Maintenance Suggestions

Regularly inspect the 3BHE013299R0002 for any signs of physical damage, such as cracks, loose connections, or corrosion.

[For power – related components] Check for overheating by feeling the surface temperature (using appropriate safety precautions). If it’s a circuit breaker, test its tripping function periodically according to the manufacturer’s guidelines.

[For automation – related components] Monitor the data transmission for any errors or delays. Clean the module and sensors (if applicable) regularly to ensure accurate data collection. Replace any worn – out parts with genuine ABB replacement parts to maintain the performance and reliability of the product.

Service and Guarantee Commitment

ABB offers a comprehensive service and guarantee for the 3BHE013299R0002. The product typically comes with a standard warranty against manufacturing defects for a specified period. In case of any issues during the warranty period, ABB’s global network of service centers can provide prompt assistance.

Customers can expect technical support for installation, commissioning, and troubleshooting. ABB also offers training programs for customers on how to use and maintain the product effectively. In addition, ABB ensures the availability of genuine replacement parts, minimizing downtime in case of component failures.