Description

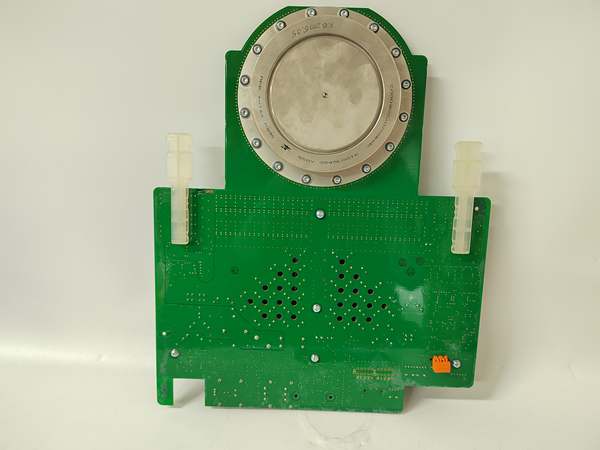

ABB 3BHE019719R0101 GVC736BE101

-

Model Number: 3BHE019719R0101 GVC736BE101 -

Manufacturer: ABB -

Product Type: Process Control Module -

Power Supply: 24 VDC (19.2-31.2 VDC range) -

Analog Inputs: 8 channels (configurable for 0-20mA, 4-20mA, 0-10V) -

Digital Inputs: 16 channels (24 VDC sourcing) -

Digital Outputs: 8 channels (24 VDC, 0.5A relay) -

Communication Protocols: Modbus TCP, PROFINET IO -

Isolation: 500 VAC channel-to-channel -

Operating Temperature: -30°C to +60°C -

Dimensions (HxWxD): 119 x 45 x 135 mm -

Weight: 0.5 kg -

Mounting: DIN rail or panel mount -

Certifications: CE, UL, cUL

ABB 3BHE019719R0101 GVC736BE101