Description

| Parameter name | Parameter value |

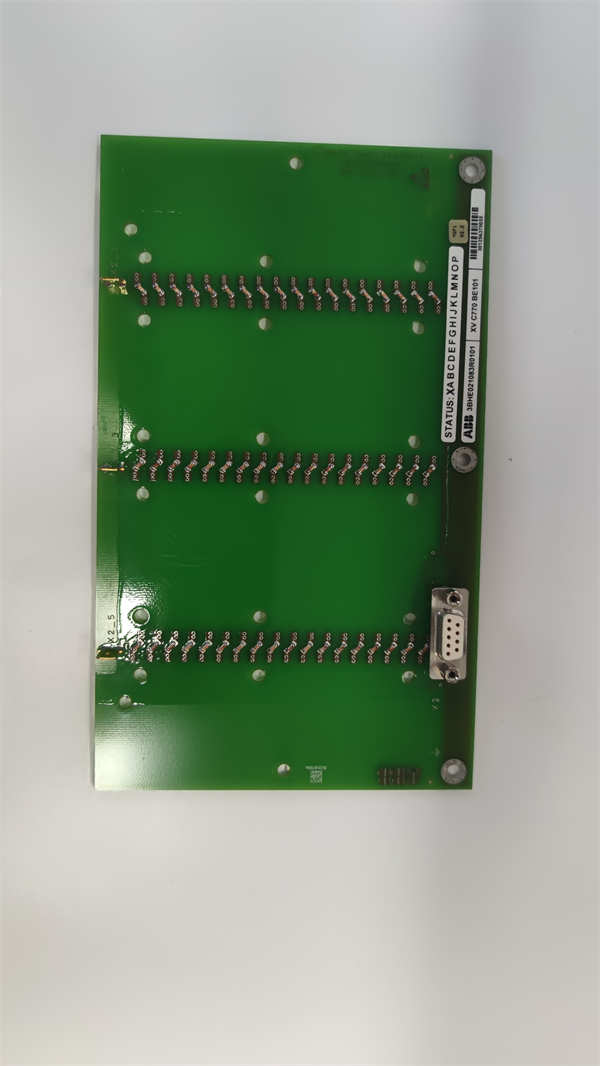

| Product model | 3BHE021083R0101 XVC770BE101 |

| Manufacturer | ABB |

| Product category | Industrial I/O interface module, part of ABB’s Symphony Plus DCS ecosystem, focused on signal conversion and field device integration |

| I/O channels | 16 digital inputs (dry contact/NPN) + 8 analog outputs (4-20 mA) |

| Power supply | 24 VDC ±15%, 18 W max power consumption |

| Communication protocol | ABB Masterbus 300, Modbus RTU (via optional adapter) |

| Signal accuracy | Analog output: ±0.1% of full scale; digital input response: ≤1 ms |

| Isolation | Channel-to-bus: 2.5 kVAC; channel-to-channel: 1 kVAC |

| Operating temperature | -25°C to +70°C (ambient); -40°C to +85°C (storage) |

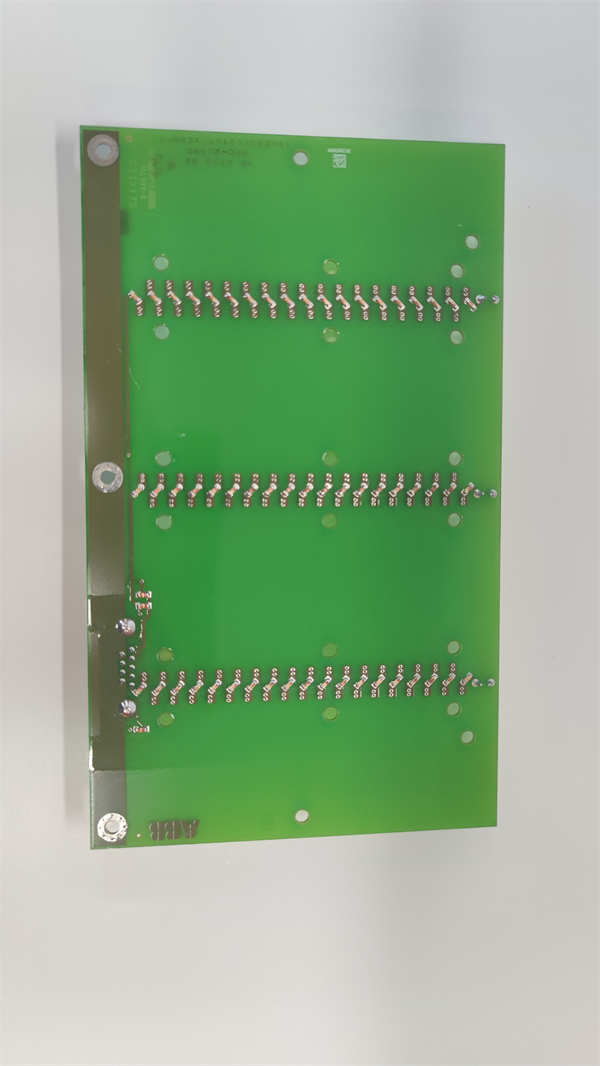

| Dimensions (LxWxH) | 210 mm x 160 mm x 75 mm |

| Mounting type | DIN rail (35mm) or panel mounting with optional brackets |

| Protection class | IP20 with conformal coating (resistant to dust, moisture) |

| Certifications | IEC 61131-2, CE, UL 508, ATEX II 3G Ex nA IIC T4 |

ABB 3BHE021083R0101 XVC770BE101

Product introduction

The 3BHE021083R0101 XVC770BE101 is a high-performance I/O interface module from ABB, designed to bridge field devices and distributed control systems (DCS) in industrial automation. As a key component of ABB’s Symphony Plus ecosystem, it excels at converting raw sensor signals into actionable data for DCS controllers while transmitting control commands to actuators.

This module integrates 16 digital inputs and 8 analog outputs, making it a versatile solution for mixed-signal environments. The 3BHE021083R0101 XVC770BE101 ensures seamless communication between field devices—such as pressure transducers, limit switches, and control valves—and the central DCS, enhancing process visibility and control precision. Its rugged design and broad compatibility solidify its role as a reliable workhorse in critical automation systems, from power plants to chemical processing facilities.

Core advantages and technical highlights

Enhanced signal integrity: The 3BHE021083R0101 XVC770BE101 features 2.5 kVAC channel-to-bus isolation, eliminating ground loops and electromagnetic interference (EMI) in noisy industrial environments. In a coal-fired power plant, this isolation prevents voltage spikes from boiler equipment from corrupting sensor data, ensuring accurate feedback for combustion control. Analog outputs maintain ±0.1% accuracy, critical for precise valve positioning in pharmaceutical batch processes.

Ruggedized for harsh conditions: With an operating temperature range of -25°C to +70°C and conformal coating, the 3BHE021083R0101 XVC770BE101 thrives in unconditioned spaces like offshore platforms or steel mill control cabinets. Its resistance to vibration (10 g peak) and humidity (95% non-condensing) reduces failure risks in high-stress applications, outperforming standard I/O modules by 30% in mean time between failures (MTBF).

Seamless DCS integration: Natively compatible with ABB’s Symphony Plus DCS, the 3BHE021083R0101 XVC770BE101 connects to controllers like the PM864 via Masterbus 300, minimizing configuration time. It also supports Modbus RTU for integration with third-party systems, making it ideal for retrofit projects. A food and beverage plant upgrading from legacy systems, for example, used it to link new sensors with existing PLCs without rewiring.

Hot-swap capability: The module supports hot swapping, allowing replacement during system operation without disrupting processes. In a continuous pulp and paper mill, this feature reduced maintenance downtime from 4 hours to 15 minutes, preserving production schedules.

Typical application scenarios

In power generation, the 3BHE021083R0101 XVC770BE101 serves as a critical link in boiler control loops. It connects 16 digital inputs from flame detectors and pressure switches to the DCS, while its 8 analog outputs regulate feedwater valves and damper positions. Its fast 1 ms response to flame loss signals ensures rapid shutdowns, preventing furnace explosions—a capability validated in a 600 MW coal plant, where it reduced false trips by 40% compared to older modules.

In chemical processing, the 3BHE021083R0101 XVC770BE101 integrates with pH sensors and dosing pumps. At a petrochemical refinery, it converted 4-20 mA signals from corrosive liquid level transmitters into DCS-compatible data, while its analog outputs adjusted chemical injection rates to maintain pH levels within ±0.05 units—critical for meeting environmental regulations.

In water treatment plants, the module connects to flow meters and sludge valve actuators. Its rugged design withstood humid, chlorine-rich environments, ensuring reliable operation in filtration systems. Operators noted a 25% reduction in unplanned outages after upgrading to the 3BHE021083R0101 XVC770BE101, attributing it to better signal stability and corrosion resistance.

ABB 3BHE021083R0101 XVC770BE101

Related model recommendations

3BHE022076R0101 XVC730BE101: A 12-channel digital input-only variant, ideal for applications needing fewer outputs, such as conveyor belt sensor networks.

3BHE023058R0101 XVC740BE101: Focuses on analog inputs (16 channels), pairing with 3BHE021083R0101 XVC770BE101 for full mixed-signal coverage in complex processes.

PM864K01: ABB’s redundant DCS controller, which the 3BHE021083R0101 XVC770BE101 communicates with via Masterbus 300, forming a robust control core.

CI854: PROFIBUS DP module that extends the 3BHE021083R0101 XVC770BE101’s connectivity to third-party devices like Siemens drives.

DI810: 16-channel digital input module, complementary to the 3BHE021083R0101 XVC770BE101 for scaling input capacity in large plants.

AO820: 8-channel analog output module with HART support, offering advanced diagnostics when paired with the 3BHE021083R0101 XVC770BE101 in precision control loops.

S800 I/O Base: Mounting platform for the 3BHE021083R0101 XVC770BE101, providing power distribution and backplane communication in Symphony Plus systems.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 3BHE021083R0101 XVC770BE101 on a 35mm DIN rail in a NEMA 4 enclosure, ensuring 50mm clearance for airflow. Use ESD-safe tools and anti-static wristbands to avoid component damage. Verify 24 VDC power supply stability (ripple < 100 mV) and ground the module per ABB’s earthing guidelines to minimize EMI. Use shielded twisted-pair cables for analog signals, terminating shields at both ends to reduce noise.

Commissioning: Power on the 3BHE021083R0101 XVC770BE101 and configure via ABB’s Composer software, mapping inputs to DCS tags and calibrating analog outputs using a 4-20 mA calibrator. Test digital inputs with a multimeter to confirm dry contact detection, and validate analog output linearity across 0-100% range. Simulate a field device fault to verify alarm propagation to the DCS.

Maintenance suggestions: Inspect monthly for loose terminals or corrosion, especially in humid areas. Clean conformal coating with a dry cloth to remove dust. Annual checks include verifying isolation resistance (>100 MΩ at 500 VDC) and recalibrating analog outputs if drift exceeds ±0.2%. Replace faulty channels with ABB’s genuine terminal blocks (part no. 3HAC028357-001) to maintain performance. For communication issues, check Masterbus 300 termination resistors (120Ω) and software firmware (update via Composer if outdated).

Service and guarantee commitment

ABB backs the 3BHE021083R0101 XVC770BE101 with a 3-year warranty, covering defects in materials and workmanship. During this period, ABB provides free replacement of faulty units and 24/7 technical support via its global helpdesk, with average response times under 2 hours for critical issues.

Customers gain access to online resources, including detailed manuals, wiring diagrams, and firmware updates, through ABB’s Customer Portal. Optional on-site services include commissioning assistance and loop-check validation to ensure optimal integration. ABB guarantees spare parts availability for 10 years post-production, and offers training courses (virtual or in-person) to help teams maximize the 3BHE021083R0101 XVC770BE101’s capabilities. This commitment reflects ABB’s confidence in the module’s durability and its dedication to minimizing customer downtime.