Description

Detailed parameter table

| Parameter name | Parameter value |

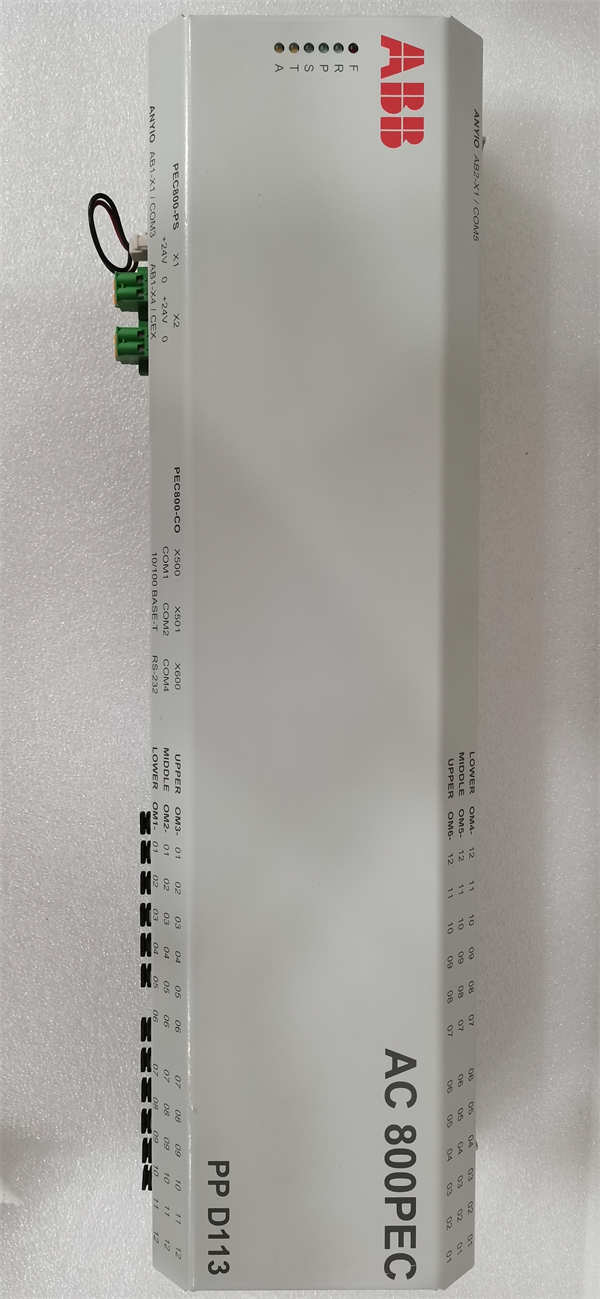

| Product model | 3BHE023784R2530 PPD113B01-25-111000 |

| Manufacturer | ABB |

| Product category | Process power distribution module (part of Symphony Plus system) |

| Input voltage | 250 VAC |

| Output channels | 8 isolated outputs |

| Output current | 10 A per channel (max) |

| Overcurrent protection | 16 A per channel (thermal-magnetic circuit breaker) |

| Isolation rating | 3 kV AC (input to output) |

| Operating temperature | 0°C to 55°C |

| Storage temperature | -40°C to 85°C |

| Humidity tolerance | 5-95% RH (non-condensing) |

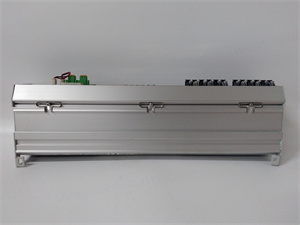

| Mounting type | Rack mount (3U height, 19-inch rack) |

| Dimensions | 132mm (height) x 483mm (width) x 300mm (depth) |

| Certifications | CE, UL, cUL, IECEx |

| Communication interface | Modbus RTU over RS-485 |

| Status indicators | LED per channel (power, overload, fault) |

ABB 3BHE023784R2530 PPD113B01-25-111000

Product introduction

The ABB 3BHE023784R2530 PPD113B01-25-111000 is a robust process power distribution module, integral to ABB’s Symphony Plus distributed control system (DCS). It is engineered to deliver reliable and protected power distribution to medium-current field devices in industrial automation settings, such as motor starters, larger solenoid valves, and industrial heaters.

Featuring 8 isolated output channels, this module ensures each connected device receives stable power while being safeguarded against electrical faults. Its seamless integration with the Symphony Plus system enables remote monitoring and management, allowing operators to efficiently track power status and address issues promptly. The ABB 3BHE023784R2530 PPD113B01-25-111000 is crucial for streamlining power distribution systems, enhancing operational safety, and ensuring uninterrupted operation of critical industrial equipment.

Core advantages and technical highlights

High-power handling capability: The ABB 3BHE023784R2530 PPD113B01-25-111000 can deliver up to 10 A per channel with a 250 VAC input, making it suitable for powering medium-current devices. This high-power handling is essential in industrial environments where equipment like motor starters or industrial heaters requires significant power to operate. For example, in a manufacturing plant, it can efficiently power the motor starters of conveyor belts, ensuring smooth material transportation.

Robust overcurrent protection: Each channel is equipped with a 16 A thermal-magnetic circuit breaker, offering reliable overcurrent and short-circuit protection. The thermal component provides delayed tripping for overloads, allowing temporary current spikes without unnecessary shutdowns, while the magnetic component trips instantly for short circuits, preventing equipment damage. This dual protection mechanism ensures optimal performance and safety in dynamic industrial settings.

Enhanced isolation: With a 3 kV AC isolation rating between input and output, and between channels, the module effectively prevents electrical interference and ground loops. This is particularly important in environments with high electromagnetic noise, such as near large motors or transformers in a steel mill. The enhanced isolation ensures that sensitive equipment connected to the module receives clean power, maintaining their accuracy and reliability.

Efficient remote monitoring and control: Via its Modbus RTU interface over RS-485, the module communicates real-time data to the Symphony Plus DCS. Operators can monitor channel status, current consumption, and fault conditions through the DCS HMI, enabling proactive maintenance. In a power generation facility, for instance, operators can remotely detect an overcurrent in a heater circuit and take corrective action before it leads to equipment failure or production downtime.

Typical application scenarios

In manufacturing plants, the ABB 3BHE023784R2530 PPD113B01-25-111000 is used to power motor starters for various production line machinery, such as mixers, pumps, and conveyors. Its high-power handling capability ensures these machines receive sufficient power, while the overcurrent protection safeguards them from electrical faults. The remote monitoring feature allows maintenance teams to track power usage and identify potential issues, minimizing unplanned downtime.

Within industrial heating systems, such as those in chemical processing or food processing plants, the module provides power to industrial heaters and temperature control valves. The robust isolation prevents electrical noise from affecting temperature sensors and controllers, ensuring precise temperature regulation. The thermal-magnetic circuit breakers protect heaters from overcurrent, extending their lifespan and ensuring safe operation.

In water and wastewater treatment facilities, the module powers medium-current equipment like large pumps and valve actuators. Its ability to handle 10 A per channel ensures these devices operate reliably, while the remote monitoring capability allows operators to monitor their power status from a central control room. This helps in efficient management of the treatment process and quick response to any equipment issues.

ABB 3BHE023784R2530 PPD113B01-25-111000

Related model recommendations

ABB 3BHE023785R2530 PPD113B01-25-111001: A variant with 250 VAC input and 12 output channels, each with a maximum current of 10 A, suitable for systems requiring more medium-current channels.

ABB 3BHE023786R2530 PPD114B01-25-111000: A 400 VAC input module with 8 output channels, ideal for industrial settings using higher AC voltage devices.

ABB Symphony Plus DCS: The distributed control system that integrates with the ABB 3BHE023784R2530 PPD113B01-25-111000 for centralized power management and monitoring.

ABB CI854A 3BSE022469R1: A Profibus DP communication module that connects the power distribution module to the Symphony Plus system, enabling fast and reliable data transmission.

ABB AC800M: A modular controller that works in conjunction with the module in medium to large-sized automation systems, providing advanced control and coordination.

ABB 800xA HMI: A human-machine interface that displays real-time data, alarms, and status information from the module, facilitating efficient operation and management.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB 3BHE023784R2530 PPD113B01-25-111000, ensure the 19-inch rack is securely mounted and properly grounded. Verify the input voltage is 250 VAC and the supply is fused at 30 A. Gather necessary tools: screwdrivers, torque wrench for rack mounting, wire strippers, and a multimeter. Plan wiring routes to separate power and signal cables to reduce electromagnetic interference. Use appropriate wire gauges (10 AWG for input, 14 AWG for outputs) and ensure all connections are torqued to 2.5 Nm.

Commissioning steps: After mounting the module, connect the 250 VAC input and field device wiring to the respective terminals, ensuring correct phase and polarity. Power on the module and check that all channel LEDs illuminate green, indicating normal operation. Use the Symphony Plus DCS to configure Modbus RTU communication (baud rate: 9600, parity: even). Perform a channel test by cycling power to each output and verify the corresponding LED responds correctly. Test the overcurrent protection by applying an 16 A+ load to a channel, confirm the breaker trips and the LED turns red, then reset the breaker to restore operation.

Maintenance suggestions: Inspect the ABB 3BHE023784R2530 PPD113B01-25-111000 quarterly for loose connections, dust accumulation, or signs of overheating. Clean vents with compressed air to ensure proper cooling. Check the status LEDs monthly to identify any fault conditions. Test the thermal-magnetic circuit breakers annually by applying overload and short-circuit currents to verify proper tripping. When replacing breakers or other components, use only ABB-approved spare parts to maintain performance and safety. Regularly back up configuration data to the DCS for quick module replacement if needed.

Service and guarantee commitment

The ABB 3BHE023784R2530 PPD113B01-25-111000 comes with a 36-month warranty from the date of purchase, covering manufacturing defects and ensuring compliance with published specifications. In case of a confirmed fault within this period, ABB will replace the module free of charge, with a guarantee of delivery within 72 hours for critical applications to minimize downtime.

ABB provides comprehensive technical support, including access to a global team of engineers via phone and email. Online resources such as installation manuals, wiring diagrams, and troubleshooting guides are available to assist with any issues. Customers can also utilize ABB’s local service centers for on-site support during installation and commissioning. Optional extended service contracts offer preventive maintenance, priority technical support, and calibration checks, ensuring the module operates reliably throughout its 15-year design lifespan.