Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3BHE030410R3011 PPD117A3011 |

| Manufacturer | ABB |

| Product category | Process power distribution module (part of Symphony Plus system) |

| Input voltage | 24 VDC |

| Output channels | 16 isolated outputs |

| Output current | 2 A per channel (max) |

| Overcurrent protection | 3 A per channel (resettable fuse) |

| Isolation rating | 2 kV AC (input to output) |

| Operating temperature | -5°C to 60°C |

| Storage temperature | -40°C to 85°C |

| Humidity tolerance | 5-95% RH (non-condensing) |

| Mounting type | Rack mount (2U height, 19-inch rack) |

| Dimensions | 88mm (height) x 483mm (width) x 260mm (depth) |

| Certifications | CE, UL, cUL, IECEx |

| Communication interface | Modbus RTU over RS-485 |

| Status indicators | LED per channel (power, overload, fault) |

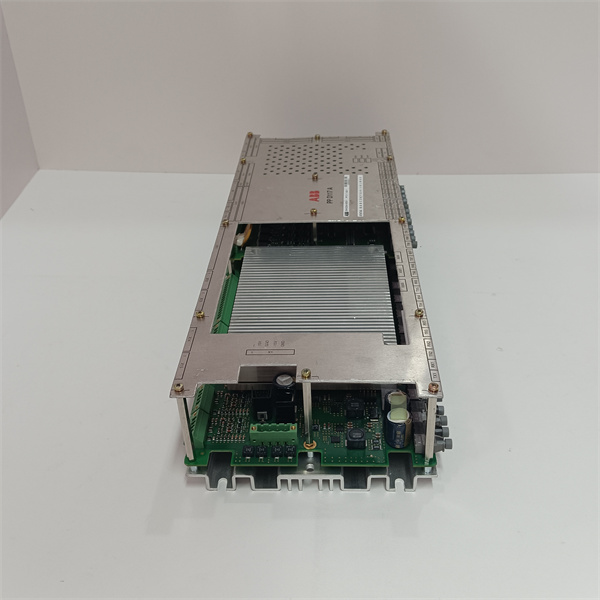

ABB 3BHE030410R3011 PPD117A3011

Product introduction

The ABB 3BHE030410R3011 PPD117A3011 is a compact and efficient process power distribution module, a key part of ABB’s Symphony Plus distributed control system (DCS). It is specifically designed to provide reliable power distribution to low-current field devices in industrial automation environments, such as transmitters, sensors, and small solenoid valves.

With 16 isolated output channels, this module ensures that each connected device receives stable and protected power. Its integration with the Symphony Plus system allows for seamless remote monitoring and management, enabling operators to keep track of power status and quickly address any issues. The ABB 3BHE030410R3011 PPD117A3011 plays a vital role in simplifying power distribution setups, enhancing system safety, and ensuring the continuous operation of critical field equipment.

Core advantages and technical highlights

High channel density: The ABB 3BHE030410R3011 PPD117A3011 features 16 output channels in a 2U rack-mount design, offering high channel density that saves valuable space in control cabinets. This is particularly beneficial in large industrial facilities where numerous low-current devices need power, as it reduces the number of modules required, simplifying the overall system architecture and lowering installation costs.

Resettable overcurrent protection: Each channel is equipped with a 3A resettable fuse, providing effective overcurrent protection. Unlike traditional fuses that need to be replaced after tripping, these resettable fuses can be easily reset, minimizing downtime and reducing maintenance costs. For example, in a food processing plant, if a sensor experiences a temporary overload, the fuse trips to protect the device, and once the issue is resolved, the fuse can be reset without needing a physical replacement.

Reliable isolation: With a 2kV AC isolation rating between input and output, and between channels, the ABB 3BHE030410R3011 PPD117A3011 prevents electrical interference and ground loops. This ensures that sensitive field devices, such as precision pressure sensors in a pharmaceutical plant, receive clean power without being affected by noise from other equipment, maintaining accurate measurements and reliable operation.

Efficient remote monitoring: The module’s Modbus RTU interface enables real-time communication with the Symphony Plus DCS. Operators can monitor the status of each channel, including power supply, current draw, and fault conditions, through the DCS HMI. This remote monitoring capability allows for proactive maintenance, as potential issues can be detected and addressed before they lead to equipment failure. In a water treatment plant, for instance, operators can remotely check if a sensor is receiving power and identify any overloads, reducing the need for on-site inspections.

Typical application scenarios

In chemical processing plants, the ABB 3BHE030410R3011 PPD117A3011 is used to power a large number of low-current devices such as pH sensors, conductivity meters, and small solenoid valves in various process loops. Its high channel density allows for centralized power distribution, making it easier to manage and monitor the power supply to these critical devices. The resettable fuses provide quick recovery in case of overloads, ensuring minimal disruption to the chemical processing operations.

Within semiconductor manufacturing facilities, where precision and cleanliness are paramount, the module powers sensitive sensors and monitoring equipment. The reliable isolation prevents electrical noise from interfering with these devices, ensuring accurate readings and maintaining the integrity of the manufacturing process. The compact design of the module also fits well in the space-constrained control cabinets typical in semiconductor plants.

In environmental monitoring systems, such as those used in wastewater treatment plants, the ABB 3BHE030410R3011 PPD117A3011 provides power to a network of sensors that measure parameters like dissolved oxygen, turbidity, and temperature. The remote monitoring feature allows operators to keep track of the power status of each sensor, ensuring that the monitoring system is always operational. This helps in timely detection of any changes in water quality and ensures compliance with environmental regulations.

ABB 3BHE030410R3011 PPD117A3011

Related model recommendations

ABB 3BHE030411R3011 PPD117A3012: A variant with 24 VDC input and 8 output channels, each with a maximum current of 5 A, suitable for powering slightly higher current devices.

ABB 3BHE030412R3011 PPD118A3011: A 48 VDC input module with 12 output channels, ideal for systems using 48 VDC field devices.

ABB Symphony Plus DCS: The distributed control system that integrates with the ABB 3BHE030410R3011 PPD117A3011 for centralized power management and monitoring.

ABB CI858 3BSE042236R1: An Ethernet/IP communication module that connects the power distribution module to the Symphony Plus system, enabling faster data transmission.

ABB AC800M: A modular controller that works in conjunction with the ABB 3BHE030410R3011 PPD117A3011 in small to medium-sized automation systems, providing local control and coordination.

ABB 800xA HMI: A human-machine interface that displays real-time data and alarms from the ABB 3BHE030410R3011 PPD117A3011, allowing operators to manage power distribution efficiently.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB 3BHE030410R3011 PPD117A3011, ensure the 19-inch rack is securely mounted and properly grounded. Verify that the input voltage is 24 VDC and the supply is fused at 10 A. Gather necessary tools: screwdrivers, torque wrench for rack mounting, and a multimeter. Plan the wiring layout to separate power and signal cables to reduce electromagnetic interference. Use appropriate wire gauges (18 AWG for input, 22 AWG for outputs) and ensure all connections are torqued to 1.2 Nm.

Commissioning steps: After mounting the module, connect the 24 VDC input and field device wiring to the respective terminals, ensuring correct polarity. Power on the module and check that all channel LEDs light up green, indicating normal operation. Use the Symphony Plus DCS to configure Modbus RTU communication (baud rate: 9600, parity: even). Perform a channel test by cycling power to each output and verify that the corresponding LED responds correctly. Test the overcurrent protection by applying a 3A+ load to a channel and confirm that the fuse trips and the LED turns red, then reset the fuse to restore operation.

Maintenance suggestions: Inspect the ABB 3BHE030410R3011 PPD117A3011 quarterly for loose connections, dust accumulation, or signs of damage. Clean the vents with compressed air to ensure proper cooling. Check the status LEDs monthly to identify any fault conditions. Test the resettable fuses annually by applying an overload current and verifying that they trip and reset properly. When replacing any components, use only ABB-approved spare parts to maintain the module’s performance and safety. Regularly back up the configuration data to the DCS to facilitate quick module replacement if needed.

Service and guarantee commitment

The ABB 3BHE030410R3011 PPD117A3011 comes with a 36-month warranty from the date of purchase, covering manufacturing defects and ensuring compliance with published specifications. In case of a confirmed fault within this period, ABB will replace the module free of charge, with a guarantee of delivery within 72 hours for critical applications to minimize downtime.

ABB provides comprehensive technical support, including access to a global team of engineers via phone and email. Online resources such as installation manuals, wiring diagrams, and troubleshooting guides are available to assist with any issues. Customers can also utilize ABB’s local service centers for on-site support during installation and commissioning. Optional extended service contracts offer preventive maintenance, priority technical support, and calibration checks, ensuring the module operates reliably throughout its 15-year design lifespan.