Description

Detailed parameter table

| Parameter Name | Parameter Value |

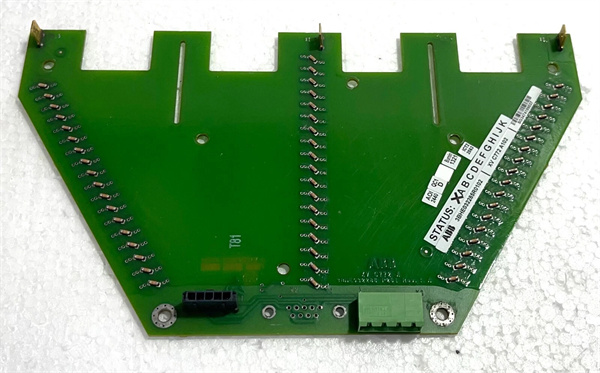

| Product model | 3BHE032285R0102 XVC772 A102 |

| Manufacturer | ABB |

| Product category | Operator interface panel (HMI for industrial control systems) |

| Display type | 5.7-inch monochrome LCD (320×240 resolution) |

| Operation method | Membrane keypad (24 function keys, 4 navigation keys) |

| Communication interface | RS-485 (Modbus RTU), Profibus DP |

| Operating voltage | 24 V DC ±15% |

| Power consumption | ≤ 6 W |

| Operating temperature | 0°C to +50°C |

| Dimensions (W×H×D) | 180 mm × 140 mm × 50 mm |

| Mounting method | Panel mounting (flush, with gasket for IP65 front protection) |

| Protection rating | IP65 (front panel), IP20 (rear) |

| Memory | 128 KB EEPROM (configuration storage), 64 KB RAM (data buffering) |

| Compatible systems | ABB AC800M controller, CI854A communication modules, XVC771 panels |

| Certification | CE, UL 508, IEC 61131-2 |

| Diagnostic features | Communication error alerts, power status LED, keypad fault detection |

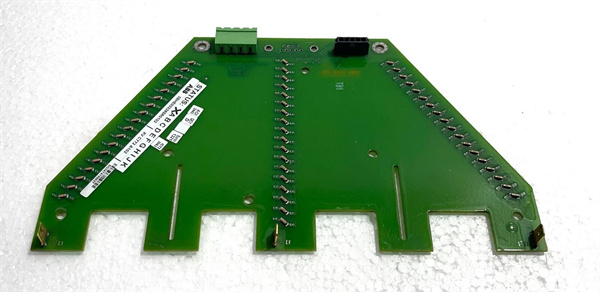

ABB 3BHE032285R0102 XVC772 A102

Product introduction

The 3BHE032285R0102 XVC772 A102 is a rugged operator interface panel from ABB, designed to facilitate intuitive interaction between operators and industrial control systems. As a key HMI component, it enables users to monitor real-time process data, adjust parameters, and execute control commands—serving as a critical link between human operators and automated equipment.

This panel features a 5.7-inch monochrome LCD display paired with a durable membrane keypad, balancing clarity and robustness for industrial environments. The 3BHE032285R0102 XVC772 A102 supports Modbus RTU and Profibus DP, ensuring seamless communication with ABB’s AC800M controllers and third-party systems. Its IP65 front protection makes it suitable for dusty or wet areas, such as factory floors or outdoor control cabinets, while the compact design fits easily into space-constrained panels. Whether used for adjusting pump speeds in water treatment or monitoring temperature in chemical reactors, this panel enhances operational efficiency through simplified control.

Core advantages and technical highlights

Industrial-grade durability

The 3BHE032285R0102 XVC772 A102’s membrane keypad and IP65 front protection withstand harsh conditions. In a steel mill’s rolling mill control room, where dust and vibration are prevalent, the keypad resists wear from frequent operation (up to 1 million presses per key) and the sealed front prevents dust ingress—ensuring reliable operation for over 10 years in typical industrial use.

Flexible communication

With support for Modbus RTU and Profibus DP, the 3BHE032285R0102 XVC772 A102 integrates into diverse control architectures. In a wastewater treatment plant, it communicates via Profibus DP with an AC800M controller to display pump status and tank levels, while using Modbus RTU to send setpoint adjustments to remote RLM01 I/O modules—eliminating the need for multiple interface devices.

Intuitive operation

The 24 function keys (configurable via software) and navigation pad simplify complex operations. In a food processing facility, operators can program keys to instantly access critical screens (e.g., “Mixing Tank Temp” or “Fill Level Alerts”), reducing response time to process deviations by up to 25% compared to menu-driven interfaces. The monochrome LCD, optimized for industrial lighting, remains readable even in bright or dim conditions.

Typical application scenarios

In a power plant’s boiler control system, the 3BHE032285R0102 XVC772 A102 serves as the primary operator interface for boiler operators. The display shows real-time data such as steam pressure, fuel flow, and flue gas temperature, while function keys are programmed to trigger common actions: starting/stopping feedwater pumps, adjusting damper positions, or acknowledging alarms.

Operators use the keypad to navigate between screens, setting new pressure setpoints that are transmitted via Profibus DP to the AC800M controller—ensuring precise control of combustion processes. The IP65 front protection allows occasional cleaning with water-based solutions, critical in areas where steam or condensation is present, while the robust keypad withstands the repetitive use common in 24/7 power generation operations.

In a mining conveyor system, the panel monitors belt speed, motor current, and emergency stop status. Its compact size fits into the conveyor’s local control panel, allowing on-site operators to troubleshoot jams or adjust speed without accessing the central control room—minimizing downtime during shifts.

Related model recommendations

3BHE032286R0101 XVC771 A101: Compact variant with a 4.3-inch display, ideal for space-limited applications requiring fewer functions than 3BHE032285R0102 XVC772 A102.

3BHE032287R0103 XVC773 A103: Advanced model with color LCD, offering enhanced visualization for complex processes needing more detail than 3BHE032285R0102 XVC772 A102.

CI854A: Profibus DP adapter that facilitates communication between 3BHE032285R0102 XVC772 A102 and AC800M controllers.

AC800M PM864: ABB controller that exchanges real-time data with 3BHE032285R0102 XVC772 A102 via Profibus DP.

XVC768 AE101: Membrane keypad replacement kit for 3BHE032285R0102 XVC772 A102, extending service life.

TB820: Terminal base that provides secure wiring connections for 3BHE032285R0102 XVC772 A102’s power and communication lines.

1MRS050644: Motor protection relay whose status data can be displayed on 3BHE032285R0102 XVC772 A102 via Modbus RTU.

ABB 3BHE032285R0102 XVC772 A102

Installation, commissioning and maintenance instructions

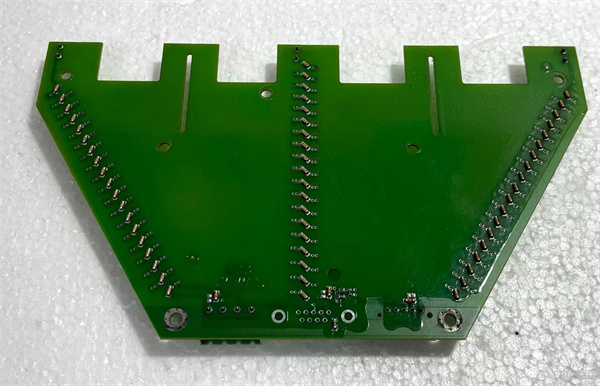

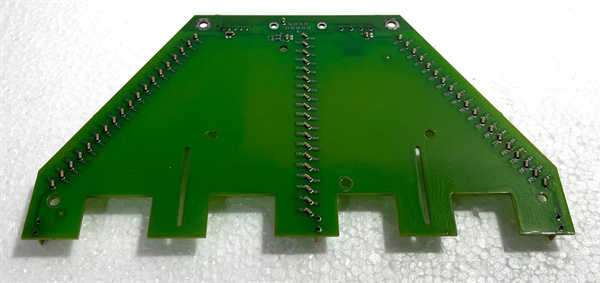

Installation preparation: Mount 3BHE032285R0102 XVC772 A102 in a panel cutout (165 mm × 125 mm) using the supplied gasket to ensure IP65 protection. Connect 24 V DC power (fused at 1 A) to the rear terminals, verifying correct polarity. For communication, wire RS-485 or Profibus DP cables (shielded, 0.5-0.75 mm²) to the designated ports, grounding shields at the panel entry. Configure keypad functions and communication parameters using ABB’s Panel Builder software before final mounting.

Maintenance suggestions: Inspect 3BHE032285R0102 XVC772 A102 monthly by checking the power LED (green indicates normal operation) and testing keypad responsiveness. Clean the front panel with a damp cloth to remove dust or grease—avoid harsh chemicals. If communication errors occur, check cable continuity and termination resistors. Replace the membrane keypad (using XVC768 AE101) if keys fail to register. For display issues, verify power supply stability before replacing the unit—use only ABB-approved replacements to maintain compatibility.

Service and guarantee commitment

The 3BHE032285R0102 XVC772 A102 is backed by a 2-year warranty covering defects in materials and workmanship. ABB’s technical support team provides guidance on configuration, software programming, and integration with control systems, including access to Panel Builder software and wiring diagrams specific to this model.

Customers receive assistance with customizing keypad functions to match operational needs, ensuring optimal usability. ABB maintains global stock of replacement panels and spare parts to minimize downtime. Our commitment to reliability ensures the 3BHE032285R0102 XVC772 A102 delivers consistent performance in industrial environments, supporting efficient and safe operation of control systems.