Description

Detailed parameter table

| Parameter Name | Parameter Value |

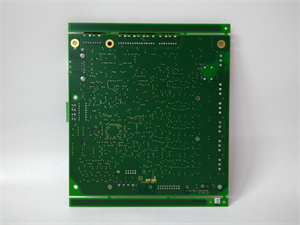

| Product model | 3BHE037864R0106 |

| Manufacturer | ABB |

| Product category | Control board (for ABB industrial robots and motion control systems) |

| Processor | 32-bit ARM Cortex-A9 (dual-core, 800 MHz) |

| Memory | 512 MB DDR3 RAM, 256 MB Flash memory |

| Operating voltage | 24 V DC ±10% |

| Power consumption | ≤ 15 W |

| Operating temperature | 0°C to +50°C |

| Dimensions (W×H×D) | 180 mm × 120 mm × 30 mm |

| Mounting method | Screw mounting via integrated standoffs |

| Communication interfaces | Ethernet (10/100 Mbps), CANopen, RS-485 |

| I/O connectors | 2 × 50-pin D-sub, 1 × 25-pin D-sub |

| Certification | CE, UL 508, RoHS |

| Compatible systems | ABB IRB 6700 robots, IRC5 controller, 3BHE037865R0101 expansion modules |

ABB 3BHE037864R0106

Product introduction

The 3BHE037864R0106 is a high-performance control board from ABB, engineered to manage motion control and peripheral device communication in industrial robot systems. As a key component in ABB’s robot control architecture, it processes sensor data, executes motion algorithms, and coordinates with the main controller to ensure precise robot movements.

This board is specifically designed for integration with ABB’s IRB 6700 robot series and IRC5 controllers, providing the computational power needed for complex robotic tasks such as welding, material handling, and assembly. The 3BHE037864R0106 features multiple communication interfaces and I/O connectors, enabling seamless connectivity with end-effectors, vision systems, and safety devices. Its compact design and robust construction make it suitable for the demanding environments of automotive factories, electronics plants, and logistics centers, where reliable robot performance is critical to production efficiency.

Core advantages and technical highlights

Powerful processing capability: The dual-core ARM Cortex-A9 processor in the 3BHE037864R0106 delivers the computational power required for real-time motion control algorithms. In automotive welding applications, this allows the board to process joint position data from vision systems and adjust robot arm movements within 2 ms, ensuring weld seam accuracy within ±0.1 mm—critical for structural integrity in vehicle manufacturing.

Multi-interface flexibility: Equipped with Ethernet, CANopen, and RS-485, the 3BHE037864R0106 seamlessly connects to diverse factory systems. In an electronics assembly line, it communicates via Ethernet with the factory MES to receive production schedules, uses CANopen to control a gripper end-effector, and connects via RS-485 to safety scanners—all while maintaining synchronized operation with the IRC5 controller.

Industrial-grade durability: The 3BHE037864R0106 is built to withstand the harsh conditions of manufacturing floors, with resistance to vibration, temperature fluctuations, and electrical noise. In a foundry robot cell with ambient temperatures up to 45°C and metal dust, the board maintains stable performance, ensuring consistent operation of the IRB 6700 robot’s casting handling tasks.

Typical application scenarios

In an automotive body shop, the 3BHE037864R0106 serves as the motion control hub for an IRB 6700 robot performing spot welding. It processes position feedback from encoders in each robot joint, calculates optimal movement paths using built-in motion algorithms, and sends control signals to the servo drives. The board’s Ethernet interface connects to a vision system that identifies weld points on car body panels, while CANopen communication controls the welding gun’s electrode force and timing.

In a logistics automation center, the 3BHE037864R0106 enables an IRB 6700 robot to sort packages of varying sizes. It receives package dimension data from a 3D scanner via RS-485, coordinates with the IRC5 controller to adjust gripper position, and uses Ethernet to update the warehouse management system on package locations. The board’s robust design ensures reliable operation in the dusty, high-throughput environment, minimizing robot downtime during peak shipping periods.

Related model recommendations

3BHE037865R0101: Expansion board for 3BHE037864R0106 that adds additional I/O ports for complex end-effectors.

3BHE037866R0102: Communication adapter that extends 3BHE037864R0106‘s connectivity to Profinet networks.

IRC5: ABB’s robot controller that integrates with 3BHE037864R0106 for complete robot management.

IRB 6700: ABB’s industrial robot series that uses 3BHE037864R0106 for motion control.

3BHE037867R0103: Power supply module specifically designed for 3BHE037864R0106.

3BHE037868R0104: Safety interface board that works with 3BHE037864R0106 to implement robot safety functions.

ABB 3BHE037864R0106

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 3BHE037864R0106 in the designated slot within the IRC5 controller or robot cabinet using the provided standoffs, ensuring a secure fit to prevent vibration-induced damage. Connect the 24 V DC power supply using the dedicated connector, verifying correct polarity and a fused (2 A) power source. Attach communication cables to the Ethernet, CANopen, and RS-485 ports, using shielded cables with shields grounded at both ends. Ensure all I/O connectors are properly seated to prevent signal interruptions.

Maintenance suggestions: Inspect the 3BHE037864R0106 quarterly for loose connections or signs of dust accumulation. Clean the board with compressed air (using low pressure) to remove debris from connectors and cooling vents. Check for corrosion on I/O pins annually, especially in humid environments. If communication errors occur, verify cable integrity before replacing the board. Update firmware semi-annually using ABB’s RobotStudio software to ensure compatibility with the latest robot control features. Replace the board only with ABB-approved units to maintain system integrity.

Service and guarantee commitment

The 3BHE037864R0106 comes with a 1-year warranty covering defects in materials and workmanship under normal operating conditions. ABB’s robotics technical support team provides specialized assistance for integration with IRB 6700 robots and IRC5 controllers, including troubleshooting guidance and firmware updates.

Customers receive access to detailed installation manuals and wiring diagrams specific to the 3BHE037864R0106, along with training resources for maintenance personnel. ABB maintains a global inventory of replacement boards to minimize downtime for critical robotic systems. Our service network offers on-site support for complex installations, ensuring the 3BHE037864R0106 operates at peak performance throughout its service life.