Description

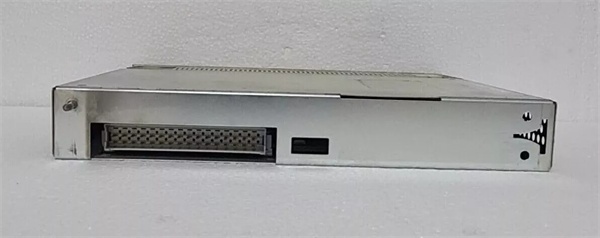

ABB 3BHT300057R1

-

Model Number: 3BHT300057R1 -

Manufacturer: ABB -

Product Type: Fieldbus Communication Interface Module -

Protocol Support: Profibus DP V1 (up to 12 Mbps, RS485 physical layer) -

Number of Slaves Supported: 1 (single-port configuration) -

I/O Data Capacity: 16 bytes input / 16 bytes output per slave -

Isolation Voltage: 500V AC (channel-to-bus, channel-to-ground) -

Operating Temperature: -25°C to +60°C -

Humidity Range: 5% to 95% non-condensing -

Power Supply: 24V DC (from Symphony Harmony rack backplane, 18-32V DC range) -

Power Consumption: 2.5W (typical) -

Communication Interface: RS485 (Profibus DP), integrated with Symphony Harmony backplane -

Dimensions: 25mm x 128mm x 115mm (width x height x depth, fits Symphony I/O rack) -

Weight: 0.18kg -

Certifications: CE, UL, cULus, RoHS

ABB 3BHT300057R1