Description

3HAA0001-AA: Product Overview

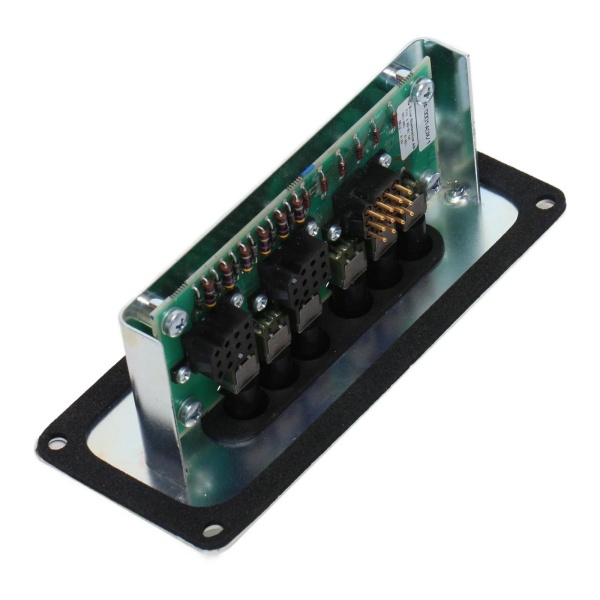

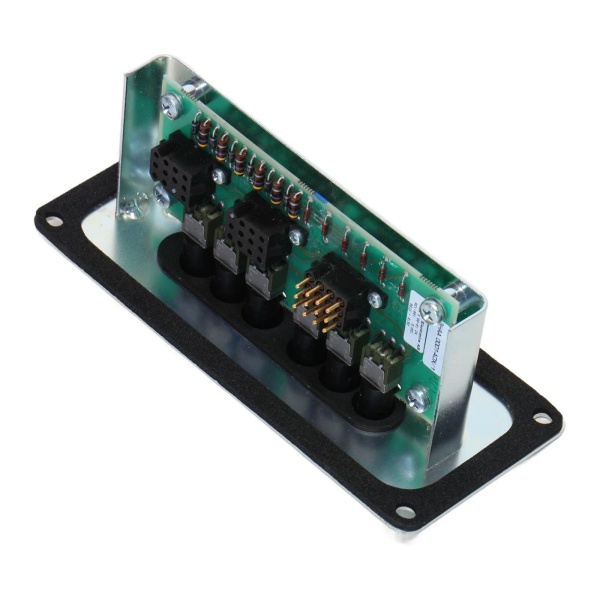

The ABB 3HAA0001-AA is a legacy I/O module designed for integration into ABB’s Advant Master distributed control system (DCS), a widely used platform for industrial process automation in industries such as power generation, chemical processing, and manufacturing. As part of the Advant Master ecosystem, the 3HAA0001-AA acts as a critical interface between field devices (e.g., pressure sensors, temperature transmitters, solenoid valves) and the DCS controller, enabling real-time data acquisition and control signal transmission.

Role in Automation Systems:

Positioned as a “field-to-controller” interface, the 3HAA0001-AA performs two primary functions:

-

Signal Acquisition: Receives analog (4–20 mA, 0–10 V) and digital (24 V DC) signals from field devices, converting them into digital data for processing by the Advant Master controller.

-

Control Output: Transmits digital or analog control signals from the controller to field actuators (e.g., valves, motors), enabling precise adjustment of process variables (e.g., flow rate, temperature).

Core Functionality:

-

Analog Signal Processing: Supports 4–20 mA current loops and 0–10 V voltage inputs, with built-in filtering and amplification to ensure accurate signal transmission.

-

Digital Signal Handling: Processes 24 V DC digital inputs (e.g., limit switches, pushbuttons) and outputs (e.g., relay contacts, solenoid valves) for discrete control applications.

-

Hot-Swappable Design: Allows for module replacement without shutting down the DCS, minimizing downtime during maintenance (inferred from Advant Master I/O standards).

Platform Benefits (Advant Master DCS):

The 3HAA0001-AA leverages ABB’s Advant Master platform, which is renowned for:

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in harsh environments (e.g., high temperature, vibration).

-

Scalability: Supports expansion with additional I/O modules to accommodate growing operational needs.

-

Legacy Support: Widely used in industries with long-lifecycle assets (e.g., power generation, oil & gas), ensuring compatibility with existing infrastructure.

ABB 3HAA0001-AA

Technical Specifications

Model Number: 3HAA0001-AA

Manufacturer: ABB

Product Type: I/O Module

-

Compatibility: ABB Advant Master DCS (Advant Controller 410/450)

-

Signal Type: Analog (4–20 mA, 0–10 V) and Digital (24 V DC)

-

Number of Channels: 8–16 (typical for Advant Master I/O modules, inferred)

-

Input Voltage: 24 V DC (nominal)

-

Output Current: 0.5 A per channel (max, digital outputs)

-

Isolation: 1500 V AC galvanic isolation (channel-to-controller, inferred)

-

Operating Temperature: -20°C to +60°C (-4°F to 140°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5–95% non-condensing

-

Protection Rating: IP20 (front panel)

-

Dimensions (W×H×D): 100 mm × 150 mm × 50 mm (3.94 in × 5.91 in × 1.97 in, inferred from similar modules)

-

Weight: 0.3 kg (0.66 lbs, inferred)

-

Certifications: CE, UL (inferred from ABB industrial product standards)

Core Features & Customer Value

1. Reliable Signal Transmission:

The 3HAA0001-AA’s analog signal processing capabilities (4–20 mA, 0–10 V) ensure accurate data acquisition from field devices, even in electrically noisy environments. For example, in a chemical plant, this module can reliably transmit pressure signals from a transmitter to the DCS controller, enabling precise control of chemical reactions.

2. Flexible I/O Configuration:

With support for both analog and digital signals, the 3HAA0001-AA adapts to diverse field device requirements. This flexibility reduces the need for additional hardware, simplifying system design and lowering costs.

3. Easy Maintenance with Hot-Swap Design:

The module’s hot-swappable design allows technicians to replace it without shutting down the DCS, minimizing downtime during maintenance. This is essential for industries like power generation, where continuous operation is required.

4. Compatibility with Legacy Systems:

As part of the Advant Master DCS family, the 3HAA0001-AA is compatible with ABB’s Advant Controller 410/450 and S100/S600 I/O racks. This ensures seamless integration with existing infrastructure, reducing the cost and complexity of upgrading or expanding systems.

ABB 3HAA0001-AA

Typical Applications

The ABB 3HAA0001-AA is widely used in industries requiring reliable I/O for process automation:

-

Power Generation:

-

Interfaces with turbine sensors (e.g., temperature, pressure) and actuator (e.g., governor valves) to maintain optimal power output.

-

Example: In a thermal power plant, the module transmits temperature signals from a turbine to the DCS controller, which adjusts the fuel flow to maintain efficiency.

-

-

Chemical Processing:

-

Connects pressure transmitters and temperature sensors to the DCS, enabling real-time monitoring of reactor conditions.

-

Example: In a petrochemical refinery, the module acquires pressure signals from a reactor and sends control signals to a valve, adjusting the flow of reactants.

-

-

Manufacturing:

-

Controls conveyor belts and robotic arms via digital I/O signals, synchronizing production processes.

-

Example: In an automotive assembly plant, the module sends digital signals to a robotic arm, enabling it to pick up a car door and place it accurately.

-