Description

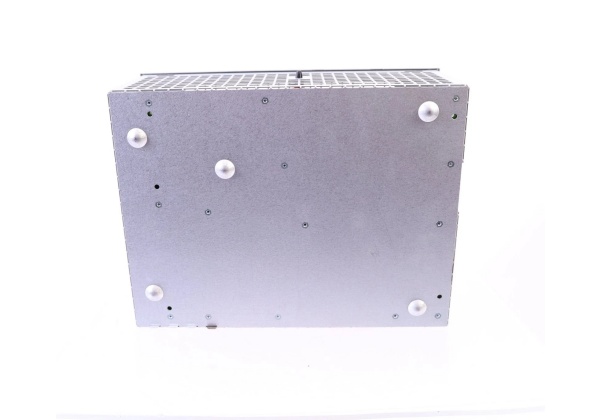

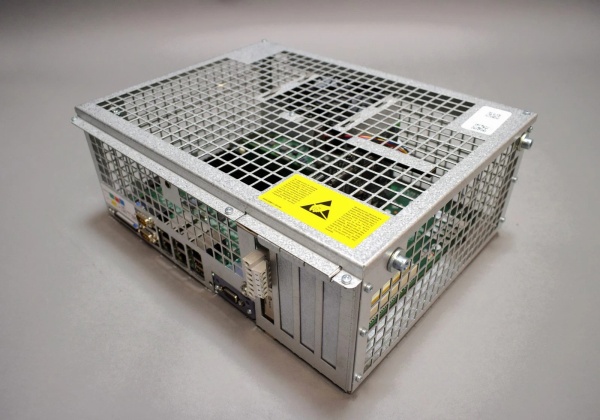

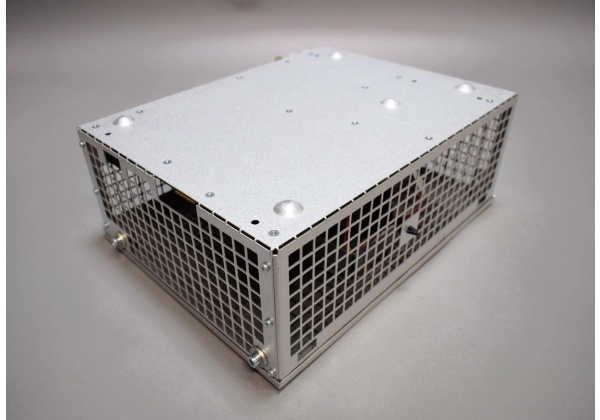

ABB 3HAC026611-001

-

Model Number: 3HAC026611-001 -

Manufacturer: ABB -

Product Type: Industrial Robotic Controller -

Processor: Multi-core, up to 1.2 GHz -

Communication Protocols: PROFINET, EtherNet/IP, DeviceNet, Modbus TCP/IP, CANopen -

I/O Capacity: Up to 128 digital inputs/outputs (DI/DO), 64 analog inputs/outputs (AI/AO) (expandable via modular I/O) -

Safety Features: Safe Torque-Off (STO), Emergency Stop (E-stop), Collision Detection, ISO 13849 Category 3 PL d -

Operating Temperature: 0°C to +55°C (storage: -20°C to +70°C) -

Power Supply: 24V DC (nominal, 20.4-28.8V DC range), with over/undervoltage protection -

Memory: 4GB RAM (user-configurable), 8GB flash storage (program/data) -

Dimensions: 200mm x 150mm x 100mm (H x W x D, base unit) -

Weight: 1.5kg (base unit) -

Protection Rating: IP20 (dust-protected) -

Certifications: CE, UL, cULus, RoHS

ABB 3HAC026611-001