Description

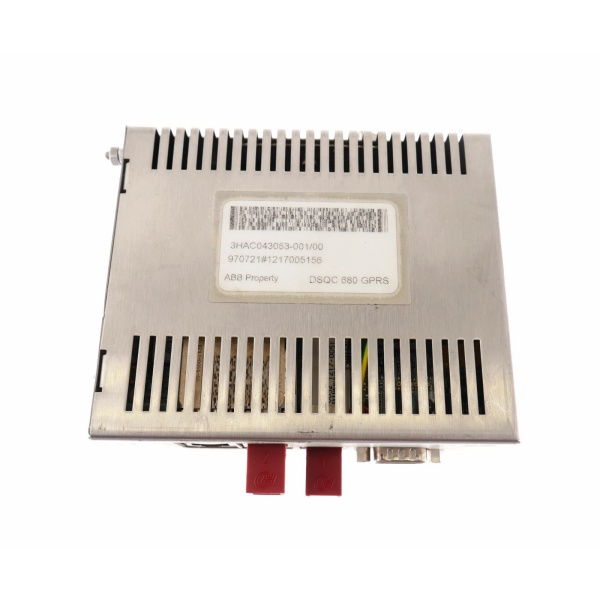

ABB 3HAC043053-001

-

Model Number: 3HAC043053-001 -

Manufacturer: ABB -

Product Type: Digital I/O Module -

Number of Channels: 16 (8 input, 8 output) -

Input Type: 24VDC dry contact (NPN/PNP compatible), sinking/sourcing -

Output Type: 24VDC transistor (sourcing), 0.5A per channel (max) -

Electrical Isolation: Channel-to-channel and channel-to-bus (1500Vrms) -

Power Supply: 24VDC (±10% tolerance, supplied by IRC5 controller) -

Operating Temperature: -25°C to +55°C -

Storage Temperature: -40°C to +70°C -

Protection Rating: IP20 (dust and light splash resistant) -

Mounting: IRC5 controller cabinet (plug-in module) -

Dimensions: 110mm x 25mm x 120mm (WxHxD) -

Weight: 0.18kg

ABB 3HAC043053-001