Description

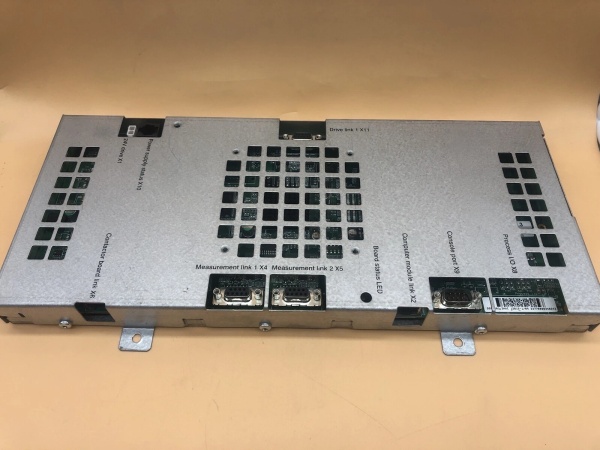

ABB 3HAC12815-1 DSQC601

-

Model Number: 3HAC12815-1 DSQC601 -

Manufacturer: ABB -

Product Type: Main Computer Board -

Controller Platform: ABB IRC5 / S4C+ -

Processor: Intel Celeron M -

Memory: 512 MB RAM, 256 MB Flash -

Ethernet Ports: 2 x 10/100/1000Base-T -

Serial Ports: 1 x RS-232 -

Fieldbus Support: DeviceNet, Profibus (via optional modules) -

Operating Voltage: 24 V DC (from controller backplane) -

Operating Temperature: 0°C to +55°C -

Dimensions: Approx. 300mm x 200mm -

Weight: Approx. 0.5 kg

ABB 3HAC12815-1 DSQC601