Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3HAC14550-408A |

| Manufacturer | ABB |

| Product category | Robot control module (IRC5 controller system) |

| Compatibility | ABB IRC5 and IRC5 Compact robot controllers |

| Processor | 32-bit ARM Cortex-A8 (800 MHz) |

| Memory | 512 MB RAM, 2 GB flash storage |

| I/O interfaces | 16 digital inputs, 16 digital outputs |

| Communication ports | 1 x Ethernet (10/100 Mbps), 1 x USB 2.0 |

| Operating voltage | 24 VDC ±10% |

| Power consumption | Max 12 W |

| Operating temperature | 0°C to 45°C |

| Protection rating | IP20 |

| Dimensions | 120mm × 80mm × 60mm |

| Weight | 0.55kg |

| Certifications | CE, UL, cUL, RoHS |

| Mounting type | DIN rail (35mm) or panel mount |

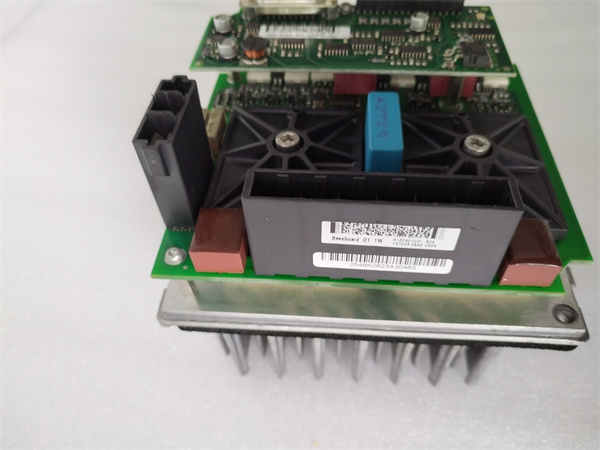

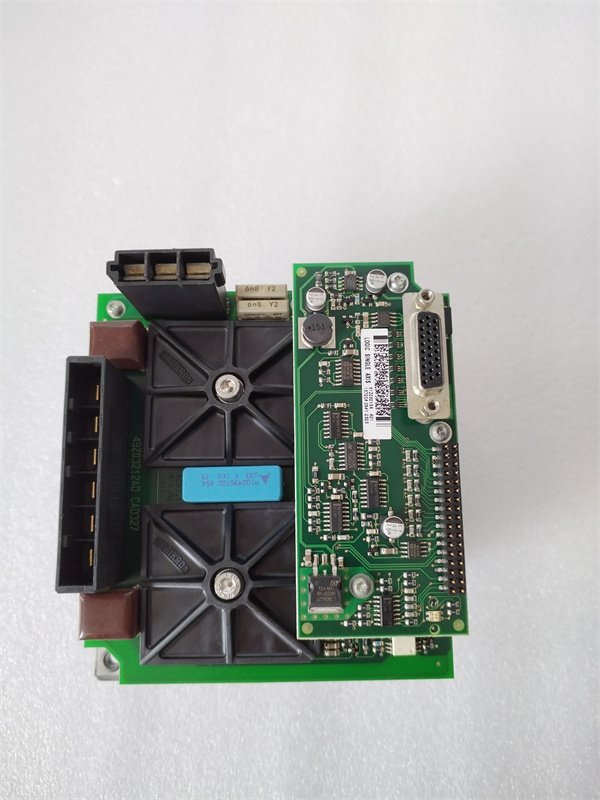

ABB 3HAC14550-408A

Product introduction

The ABB 3HAC14550-408A is a specialized robot control module designed as a key component of ABB’s IRC5 robot controller system, a leading platform in industrial robotics for manufacturing, logistics, and automation. This module serves as an interface between the IRC5 controller and peripheral devices, enabling precise control of auxiliary equipment and seamless integration of robotic cells into larger production systems.

Equipped with 16 digital inputs and 16 digital outputs, the ABB 3HAC14550-408A facilitates real-time communication between the robot controller and external devices such as grippers, conveyors, and safety sensors. Its embedded processor and memory allow for local processing of simple control logic, reducing the load on the main IRC5 controller and improving system responsiveness.

Within robotic automation systems, the ABB 3HAC14550-408A plays a critical role in expanding the functionality of IRC5 controllers. It enables synchronized operation between robots and auxiliary equipment, supports complex sequence control, and enhances system flexibility by allowing customization of I/O configurations to match specific application requirements. This versatility makes it an essential component in modern industrial robot cells.

Core advantages and technical highlights

Seamless IRC5 integration: The ABB 3HAC14550-408A is specifically engineered for ABB’s IRC5 controller family, ensuring plug-and-play compatibility and eliminating integration issues common with third-party modules. It communicates directly with the controller via a dedicated internal bus, enabling low-latency data exchange and synchronized operation. This integration allows for centralized programming and monitoring through ABB’s RobotStudio software, simplifying system setup and reducing commissioning time.

Enhanced I/O capacity: With 16 digital inputs and 16 digital outputs, the ABB 3HAC14550-408A significantly expands the I/O capabilities of IRC5 controllers, supporting complex automation scenarios. Each I/O channel can be individually configured for specific voltage levels (24 VDC) and response times, allowing connection to diverse devices from proximity sensors to pneumatic valve manifolds. This flexibility eliminates the need for external I/O expansion units in medium-scale robotic cells.

Local processing capability: The embedded 800 MHz ARM Cortex-A8 processor in the ABB 3HAC14550-408A enables local execution of simple control logic, such as conveyor synchronization or gripper actuation sequences. This distributed processing reduces the workload on the main robot controller, improving overall system performance and allowing the IRC5 to focus on high-priority tasks like motion control and path planning. In high-speed pick-and-place applications, this can reduce cycle times by up to 10%.

Robust industrial design: Built to withstand the rigors of factory environments, the ABB 3HAC14550-408A operates reliably in temperatures from 0°C to 45°C and tolerates vibration up to 5g. Its IP20 rating protects against dust ingress, while ruggedized components ensure a long service life in harsh manufacturing conditions. The module’s DIN rail mounting design allows for easy installation in control cabinets, saving space and simplifying wiring.

Typical application scenarios

In automotive assembly plants, the ABB 3HAC14550-408A enables robotic welding cells to coordinate with material handling systems. It connects the IRC5 controller to conveyor sensors (digital inputs) and motor starters (digital outputs), ensuring parts are delivered to the robot precisely when needed. The module’s local processing capability handles conveyor speed synchronization, reducing the main controller’s workload and improving welding cycle efficiency.

Within electronics manufacturing, the ABB 3HAC14550-408A integrates pick-and-place robots with vision systems and feeders. It processes input signals from vision cameras to confirm component alignment and activates output signals to control feeder mechanisms, ensuring accurate placement of small electronic components. Its compact size makes it ideal for installation in space-constrained cleanroom environments.

In logistics automation, the ABB 3HAC14550-408A connects palletizing robots to warehouse management systems via Ethernet. It receives order data (via USB for local storage) and controls pallet conveyors, layer shifters, and stretch wrappers through its digital outputs. The module’s I/O flexibility allows easy reconfiguration for different pallet sizes and stacking patterns, supporting quick changeovers between product lines.

ABB 3HAC14550-408A

Related model recommendations

ABB 3HAC17484-1: A higher-capacity I/O module with 32 digital inputs/outputs, compatible with the ABB 3HAC14550-408A for larger-scale robotic systems.

ABB IRC5 Compact Controller: The main controller that works with the ABB 3HAC14550-408A to manage robot motion and auxiliary equipment.

ABB RobotStudio: Programming software used to configure the ABB 3HAC14550-408A and simulate I/O interactions in robotic cells.

ABB DSQC651: A safety I/O module that complements the ABB 3HAC14550-408A by handling safety-related signals in robotic systems.

ABB 3HAC028357-001: A power supply module that provides stable 24 VDC to the ABB 3HAC14550-408A and other IRC5 components.

ABB IRB 6700: A heavy-duty industrial robot commonly paired with the ABB 3HAC14550-408A for material handling and spot welding applications.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB 3HAC14550-408A, ensure the 35mm DIN rail or panel is securely mounted in the robot control cabinet and properly grounded. Verify the ambient temperature is within 0°C to 45°C and humidity is below 90% RH (non-condensing). Required tools include a torque screwdriver (0.5-0.8 Nm), wire strippers, and a multimeter. Use 0.5-1.0 mm² shielded cables for I/O connections, with shields grounded at the module end to minimize electrical noise.

Maintenance suggestions: Inspect the ABB 3HAC14550-408A monthly for loose connections or dust buildup; clean with compressed air if necessary. Check the status LED regularly—steady green indicates normal operation, while red or flashing LEDs signal communication or power issues. Test I/O functionality quarterly using RobotStudio software to verify all inputs and outputs respond correctly. Back up configuration data whenever changes are made. If a fault occurs, first check power and communication connections; replace with an ABB-approved module if issues persist to maintain system compatibility.

Service and guarantee commitment

The ABB 3HAC14550-408A comes with a 24-month warranty from the date of installation, covering manufacturing defects and ensuring compatibility with IRC5 controller systems. ABB guarantees replacement of faulty modules within 72 hours for critical production applications, minimizing downtime in robotic cells.

Technical support includes access to ABB’s global robotics engineering team, available for assistance with configuration, programming, and troubleshooting. Online resources include detailed integration guides, wiring diagrams, and firmware updates specific to the ABB 3HAC14550-408A. Customers can opt for extended service contracts that include preventive maintenance, software updates, and on-site support, ensuring the module delivers reliable performance throughout its 8-year design lifespan.