Description

Detailed parameter table

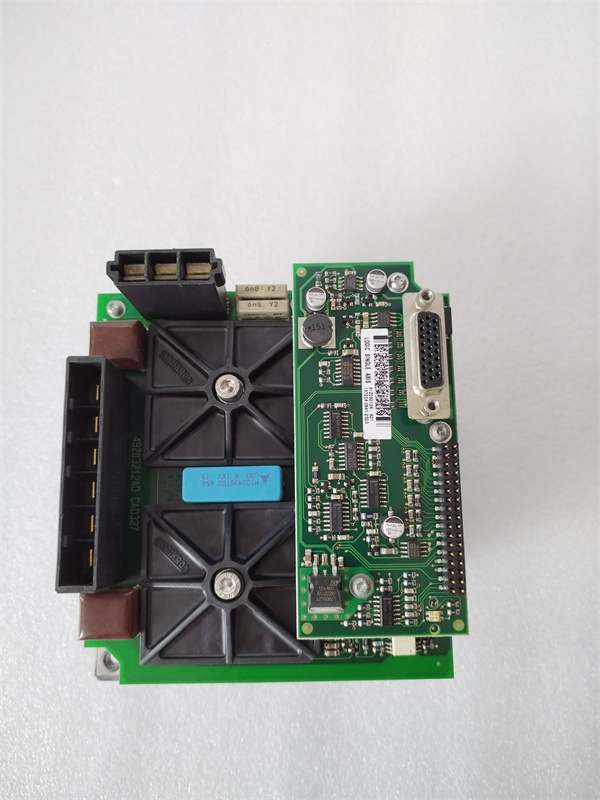

| Parameter name | Parameter value |

| Product model | 3HAC14550-408A |

| Manufacturer | ABB |

| Product category | Robot control module (servo drive interface) |

| Compatible robot series | IRB 6700, IRB 7600, IRB 8700 |

| Number of axes supported | 6 (configurable for 7-axis applications) |

| Control precision | ±0.02 mm repeatability |

| Communication interfaces | 2 x Ethernet (1000 Mbps), 1 x PROFINET IO, 1 x RS485 |

| Operating voltage | 400 V AC ±10% (3-phase) |

| Power consumption | Max 3.5 kW |

| Operating temperature | 0°C to 45°C |

| Protection rating | IP20 (module), IP54 (with enclosure) |

| Mounting type | Cabinet mount (DIN rail or panel mount) |

| Dimensions | 220mm × 300mm × 180mm |

| Certifications | CE, UL, ISO 13849-1 (PL d), IEC 61508 (SIL 2) |

ABB 3HAC14550-408A

Product introduction

The 3HAC14550-408A is a high-performance robot control module from ABB, designed as a critical interface between robot controllers and servo drives in large industrial robot systems. As a key component in ABB’s robotics portfolio, this module manages motion control signals, coordinates multi-axis movements, and ensures precise synchronization between robot joints—complementing control systems like the PCD235A101 3BHE032025R0101 PLC in integrated automation environments.

Unlike standard servo interfaces, the 3HAC14550-408A is optimized for heavy-duty robotic applications, supporting high payload robots (up to 800 kg) with exceptional repeatability. Whether deployed in automotive welding cells, heavy machinery assembly, or logistics palletizing systems, this module delivers the precision and reliability required for complex robotic tasks, ensuring consistent performance even under dynamic load conditions.

Core advantages and technical highlights

High-precision motion control: With ±0.02 mm repeatability, the 3HAC14550-408A enables robots to perform intricate tasks such as automotive body welding or aerospace component assembly with micron-level accuracy. Its advanced servo algorithms compensate for dynamic loads and inertia changes, ensuring the robot maintains path accuracy even when handling varying payloads—from empty grippers to full pallets. In a foundry application, this precision allows the module to control a 6-axis IRB 8700 robot casting molten metal into molds with consistent positioning, reducing scrap rates by 15%.

Multi-axis coordination: The module supports 6 axes natively (configurable for 7-axis systems with additional hardware), enabling synchronized control of robot arms, rotary tables, and linear tracks. In a battery manufacturing plant, this coordination allows a robot to simultaneously position a cell stack (6 axes) while a seventh axis adjusts the welding head angle, ensuring uniform electrode placement across 50+ battery cells. The module’s 1 ms update rate ensures tight synchronization between axes, preventing collisions and improving cycle times.

Seamless integration with PLC systems: Equipped with PROFINET IO and Ethernet interfaces, the 3HAC14550-408A integrates seamlessly with ABB’s PCD235A101 PLC and communication modules like the 500CIM05 1MRB150077R1/B. This connectivity enables centralized control of robotic cells within plant-wide automation systems, allowing production schedules from the MES to directly adjust robot operations. In an automotive paint shop, the PLC can pause the robot via the module if the AI880-1 analog module detects incorrect paint viscosity, ensuring quality control without manual intervention.

Safety-certified operation: Certified to ISO 13849-1 (PL d) and IEC 61508 (SIL 2), the module includes safety functions such as safe torque off (STO) and safe stop 1 (SS1). In a food and beverage packaging line, these features ensure the robot stops safely if a DTCC901B digital module detects an operator in the work envelope, preventing accidents while minimizing production downtime. Safety data is transmitted to the PLC for compliance logging and audit trails.

Robust industrial design: Built to withstand the harsh conditions of manufacturing environments, the 3HAC14550-408A operates reliably in temperatures up to 45°C and features conformal coating on circuit boards to resist dust and moisture. Its 400 V AC 3-phase power supply accommodates industrial electrical systems, while overload protection prevents damage from current spikes—critical in foundries and forging facilities with electrical noise. The module’s compact design fits into standard control cabinets, saving space in crowded robot cells.

Typical application scenarios

In an automotive final assembly plant, the 3HAC14550-408A controls an IRB 7600 robot responsible for installing windshields. It coordinates 6 axes to position the glass with ±0.1 mm accuracy relative to the car body, using vision system data (transmitted via PROFINET IO) to compensate for minor frame variations. The module integrates with the PCD235A101 PLC, which triggers the robot to start when the car body reaches the station (detected by DTCC901B sensors). Safety functions ensure the robot stops if a technician enters the cell, with diagnostic data logged for OEE analysis.

In a heavy machinery factory, the module controls a 7-axis IRB 6700 robot handling large steel components (up to 500 kg). It adjusts motion profiles in real time based on load data from strain gauges (connected via AI880-1 modules), preventing excessive vibration during lifting. The 500CIM05 communication module enables the robot to share cycle time data with the MES system, allowing production managers to optimize workflow. The module’s robust design withstands welding fumes and metal dust, ensuring reliable operation in this harsh environment.

ABB 3HAC14550-408A

Related model recommendations

3HAC14550-409A: A higher-power variant supporting robots with payloads up to 1,000 kg, ideal for heavy forging applications.

PCD235A101 3BHE032025R0101: ABB’s PLC that coordinates with the 3HAC14550-408A for cell-level control.

500CIM05 1MRB150077R1/B: ABB’s communication module that extends the robot’s connectivity to enterprise systems.

DTCC901B: ABB’s digital control module that provides sensor inputs for robot cell safety interlocks.

AI880-1: ABB’s analog input module that feeds load and pressure data to the robot control system.

DSQC 664: ABB’s safety controller that enhances the module’s safety functions in high-risk applications.

HMI80: ABB’s touchscreen panel that visualizes robot status and diagnostics from the 3HAC14550-408A.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 3HAC14550-408A in a control cabinet using DIN rail or panel screws (torque to 1.2 Nm). Ensure at least 150mm clearance for ventilation and 400 V AC 3-phase power supply with a 10A circuit breaker. Connect servo motor cables (shielded, 4 mm²) to the designated terminals, grounding shields at both ends. Attach communication cables: Cat 6a for PROFINET IO (max 100m) and Ethernet. Required tools include a torque wrench, wire strippers, and a multimeter. Power off all systems during installation.

Commissioning steps: Use ABB’s RobotStudio software to configure axis parameters (motor type, gear ratios) and motion profiles (acceleration, velocity limits). Calibrate robot kinematics using a laser tracker to achieve ±0.02 mm repeatability. Test communication with the PCD235A101 PLC by sending joint position data and verifying control commands. Validate safety functions by simulating an emergency stop and confirming STO activation within 200 ms. Perform a full cycle test with the robot handling nominal and maximum payloads to ensure path accuracy. Save configurations to non-volatile memory.

Maintenance suggestions: Inspect monthly for loose connections, dust accumulation, and LED status (power: green, communication: flashing green, fault: red). Clean heat sinks with compressed air to prevent overheating. Check servo cable insulation annually for wear, especially in robotic cells with high cable movement. Update firmware semi-annually via Ethernet (with password protection) to improve motion control algorithms. Test safety functions quarterly by triggering STO and verifying compliance with PL d requirements. Replace with an ABB-certified module if servo errors persist despite cable and motor checks.

Service and guarantee commitment

The 3HAC14550-408A comes with a 3-year warranty from installation, covering manufacturing defects and ensuring compliance with published performance specifications. ABB guarantees technical support response within 2 hours for critical robotic applications, with on-site service available in 48 hours for qualified industrial facilities. The module includes 2 years of free firmware updates and access to RobotStudio software. Extended service contracts offer preventive maintenance, calibration verification, and priority support, ensuring optimal robot performance throughout its 10-year design lifespan. Customers receive dedicated online resources, including wiring diagrams, calibration procedures, and troubleshooting guides specific to this model.

High-precision motion control: With ±0.02 mm repeatability, the 3HAC14550-408A enables robots to perform intricate tasks such as automotive body welding or aerospace component assembly with micron-level accuracy. Its advanced servo algorithms compensate for dynamic loads and inertia changes, ensuring the robot maintains path accuracy even when handling varying payloads—from empty grippers to full pallets. In a foundry application, this precision allows the module to control a 6-axis IRB 8700 robot casting molten metal into molds with consistent positioning, reducing scrap rates by 15%.

Multi-axis coordination: The module supports 6 axes natively (configurable for 7-axis systems with additional hardware), enabling synchronized control of robot arms, rotary tables, and linear tracks. In a battery manufacturing plant, this coordination allows a robot to simultaneously position a cell stack (6 axes) while a seventh axis adjusts the welding head angle, ensuring uniform electrode placement across 50+ battery cells. The module’s 1 ms update rate ensures tight synchronization between axes, preventing collisions and improving cycle times.

Seamless integration with PLC systems: Equipped with PROFINET IO and Ethernet interfaces, the 3HAC14550-408A integrates seamlessly with ABB’s PCD235A101 PLC and communication modules like the 500CIM05 1MRB150077R1/B. This connectivity enables centralized control of robotic cells within plant-wide automation systems, allowing production schedules from the MES to directly adjust robot operations. In an automotive paint shop, the PLC can pause the robot via the module if the AI880-1 analog module detects incorrect paint viscosity, ensuring quality control without manual intervention.

Safety-certified operation: Certified to ISO 13849-1 (PL d) and IEC 61508 (SIL 2), the module includes safety functions such as safe torque off (STO) and safe stop 1 (SS1). In a food and beverage packaging line, these features ensure the robot stops safely if a DTCC901B digital module detects an operator in the work envelope, preventing accidents while minimizing production downtime. Safety data is transmitted to the PLC for compliance logging and audit trails.

Robust industrial design: Built to withstand the harsh conditions of manufacturing environments, the 3HAC14550-408A operates reliably in temperatures up to 45°C and features conformal coating on circuit boards to resist dust and moisture. Its 400 V AC 3-phase power supply accommodates industrial electrical systems, while overload protection prevents damage from current spikes—critical in foundries and forging facilities with electrical noise. The module’s compact design fits into standard control cabinets, saving space in crowded robot cells.