Description

3HXC0100-208: Product Overview

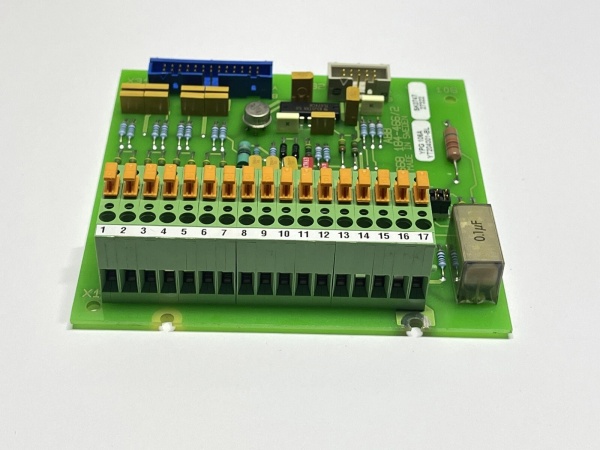

This module operates within the communication layer of ABB IRC5 robot controller systems, positioned as an expansion unit for integrating robotic arms with external automation networks. Its role is to translate controller commands into standardized industrial protocols (Ethernet/IP, PROFINET) for interaction with PLCs (e.g., ABB AC500), HMIs, or DCS (e.g., ABB 800xA), while concurrently managing I/O signals for peripheral devices (e.g., grippers, sensors, safety interlocks). In a typical robotics architecture, it mounts directly onto the IRC5 controller chassis or an adjacent DIN rail, drawing power from the controller’s auxiliary supply and synchronizing data via the robot’s internal bus.

Core functionality includes supporting multi-protocol communication (Ethernet/IP Class 1/3, PROFINET RT, Modbus TCP), processing 16 digital I/O channels (24V DC, 0.5A per output) for discrete control of end-effectors or safety circuits, and embedding diagnostic tools for monitoring network latency and I/O status. It handles signal conditioning (debounce filtering for inputs, surge suppression for outputs) and provides galvanic isolation (1.5kV RMS) between the robot controller and field circuits to mitigate ground loop interference.

The module belongs to the ABB IRC5 Robot Controller Series, a platform optimized for high-precision robotic applications. Benefits of this series include seamless integration with ABB RobotStudio simulation software for virtual commissioning, compatibility with ABB’s Robot Web Services (RWS) for remote configuration, and adherence to ISO 10218-1 safety standards for collaborative robot deployments. This series streamlines system expansion by allowing incremental addition of communication/I/O modules without replacing the core controller.

ABB YT204001-JN

3HXC0100-208: Technical Specifications

-

Model Number: 3HXC0100-208

-

Manufacturer: ABB Ltd.

-

Product Type: Robot Controller Communication Module

-

Supported Protocols: Ethernet/IP, PROFINET RT, Modbus TCP

-

Number of I/O Channels: 16 (8 digital inputs, 8 digital outputs)

-

I/O Signal Type: 24V DC (dry contact, transistor)

-

Power Supply: 24V DC (±10%, 2W max, from IRC5 controller)

-

Isolation Voltage: 1.5kV RMS (I/O-to-controller)

-

Data Transfer Rate: 10/100 Mbps (Ethernet), 9.6 kbps–12 Mbps (Modbus)

-

Operating Temperature: 0°C to +50°C (module); -20°C to +60°C (controller)

-

Storage Temperature: -40°C to +85°C

-

Protection Rating: IP20 (enclosure)

-

Dimensions: 80mm (H) x 60mm (W) x 40mm (D)

-

Weight: ~0.2kg

-

Certifications: CE, UL (cULus Listed), RoHS, ISO 10218-1

Core Features & Customer Value

Multi-protocol support (Ethernet/IP, PROFINET, Modbus TCP) eliminates the need for separate protocol converters, simplifying integration with mixed-vendor systems. For engineers, this reduces wiring complexity in automotive assembly lines, where a single module can connect a robot to a Siemens S7-1500 PLC (PROFINET) and a legacy Modbus-based vision system simultaneously. The 16 digital I/O channels enable direct control of end-effectors (e.g., vacuum gripper activation) or safety interlocks (e.g., light curtain status), removing the need for additional I/O modules.

Galvanic isolation (1.5kV RMS) protects the IRC5 controller from voltage transients generated by inductive loads (e.g., solenoid-actuated clamps), minimizing the risk of controller faults in high-cycle applications like spot welding. Channel-level diagnostics (via ABB RobotStudio) flag issues like “input 3 wire break” or “output 5 overload,” reducing mean time to repair (MTTR) for maintenance teams. The module’s compact form factor (0.2kg) and DIN rail mounting save space in robot control cabinets, critical for retrofits in crowded automotive body shops.

Compatibility with ABB Robot Web Services (RWS) allows remote configuration of I/O mapping and protocol parameters via a web browser, reducing the need for physical access to the controller in 24/7 facilities like battery manufacturing plants. The -20°C cold-start capability ensures operation in unheated warehouses or outdoor robotic cells.

ABB YT204001-JN

Typical Applications

In an automotive body shop, the module connects an ABB IRB 6700 welding robot to a Siemens S7-1500 PLC (PROFINET) for weld schedule selection and a Modbus-based torque sensor for joint quality monitoring. The 8 digital outputs activate the welding gun, while inputs read sensor feedback to adjust parameters in real time.

At a consumer electronics assembly line, it interfaces an ABB IRB 1200 pick-and-place robot with an ABB AC500 PLC (Ethernet/IP) for conveyor synchronization and a vision system (Modbus TCP) for component alignment. The I/O channels control a pneumatic gripper and read part presence sensors, ensuring cycle time consistency.

In a pharmaceutical packaging cell, the module links an ABB IRB 2600 robot to a DCS (Ethernet/IP) for batch tracking and a safety PLC for light curtain interlocks. The isolation feature protects the robot controller from transients induced by nearby carton sealers, maintaining uptime in GMP-compliant environments.