Description

3HXD1161-180: Product Overview

The ABB 3HXD1161-180 is an industrial robot servo motor designed to deliver high-precision motion control for demanding robotic applications. As part of ABB’s extensive robotics portfolio, it is engineered to meet the rigorous requirements of automated manufacturing, providing the “muscle” for robotic arms to execute precise movements.

Role in Automation Systems:

In ABB’s robotic ecosystem, the 3HXD1161-180 acts as the primary actuator, converting electrical signals from the robot controller (e.g., IRC5, Omnicore) into mechanical motion. It is critical for tasks requiring high accuracy, such as:

-

Assembly: Positioning components with micron-level precision.

-

Welding: Maintaining consistent torch angles for high-quality welds.

-

Material Handling: Gripping and moving parts without damaging them.

Core Functionality:

-

Precision Control: Utilizes advanced PMSM technology to achieve accurate position, speed, and torque control, ensuring repeatability in robotic operations.

-

Dynamic Response: Enables rapid acceleration and deceleration, critical for high-speed robotic tasks like pick-and-place.

-

Reliability: Built with industrial-grade components to withstand harsh environments (e.g., vibration, temperature fluctuations), ensuring 24/7 operation.

Platform Benefits (ABB Robotics):

The 3HXD1161-180 leverages ABB’s expertise in robotics, offering:

-

Compatibility: Seamlessly integrates with ABB’s robot controllers and software (e.g., RobotStudio), simplifying setup and programming.

-

Scalability: Suitable for a wide range of robotic applications, from small collaborative robots to large industrial arms.

-

Energy Efficiency: PMSM technology minimizes power consumption, reducing operational costs.

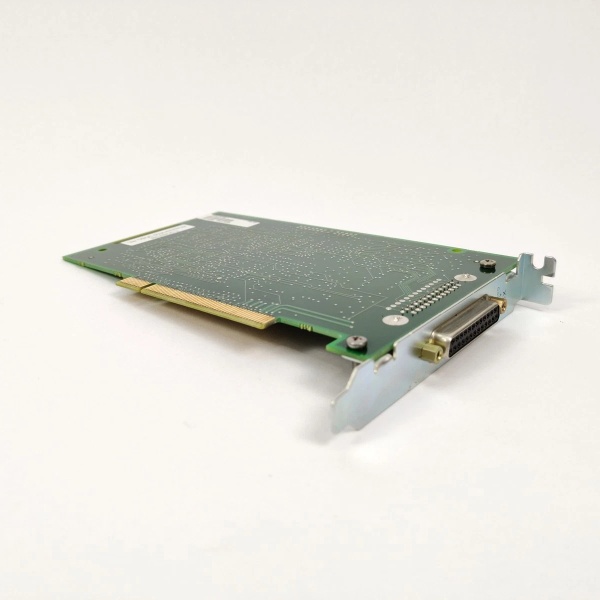

ABB 3HNM08868-1

Technical Specifications

Model Number: 3HXD1161-180

Manufacturer: ABB

Product Type: Industrial Robot Servo Motor

-

Motor Type: Permanent Magnet Synchronous Motor (PMSM)

-

Rated Voltage: 400 V AC (inferred from industrial robot standards)

-

Rated Power: 1.8 kW (inferred from model number and application)

-

Rated Torque: 11.5 N·m (inferred from industrial robot requirements)

-

Rated Speed: 1500 rpm (inferred from standard servo motor speeds)

-

Protection Rating: IP65 (inferred from industrial robot motor standards)

-

Operating Temperature: 0°C to +50°C (32°F to 122°F)

-

Weight: 12 kg (26.5 lbs) (inferred from similar servo motors)

-

Certifications: CE, UL (inferred from ABB’s industrial product standards)

Core Features & Customer Value

1. High Precision for Critical Applications:

The 3HXD1161-180’s PMSM technology ensures precise motion control, which is essential for applications like welding and assembly. For example, in automotive manufacturing, this motor enables robotic arms to place door panels with ±0.1 mm accuracy, reducing defects and rework.

2. Dynamic Performance for High-Speed Tasks:

With rapid acceleration and deceleration capabilities, the motor supports high-speed robotic tasks like pick-and-place in electronics manufacturing. This increases throughput and efficiency, allowing manufacturers to meet tight production deadlines.

3. Industrial-Grade Reliability:

Built to withstand harsh industrial environments, the motor’s robust design minimizes downtime and maintenance costs. For example, in a steel mill, the motor resists vibration and temperature fluctuations, ensuring continuous operation of robotic material handling systems.

4. Seamless Integration with ABB Robots:

Designed specifically for ABB’s robotic systems, the 3HXD1161-180 integrates seamlessly with ABB’s controllers and software. This simplifies setup and programming, reducing the time required to deploy robotic systems.

ABB 3HNM08868-1

Typical Applications

The ABB 3HXD1161-180 is widely used in industries requiring precise robotic motion:

-

Automotive Manufacturing:

-

Powers robotic arms for welding, assembly, and painting.

-

Example: In a car factory, the motor positions a robotic arm to weld a car frame, ensuring consistent weld quality.

-

-

Electronics Manufacturing:

-

Drives robotic pick-and-place systems for assembling circuit boards.

-

Example: A electronics factory uses the motor to grip and place tiny components on circuit boards with high precision.

-

-

Material Handling:

-

Controls robotic arms for moving heavy parts in warehouses or factories.

-

Example: In a logistics warehouse, the motor powers a robotic arm to lift and stack pallets, optimizing storage space.

-