Description

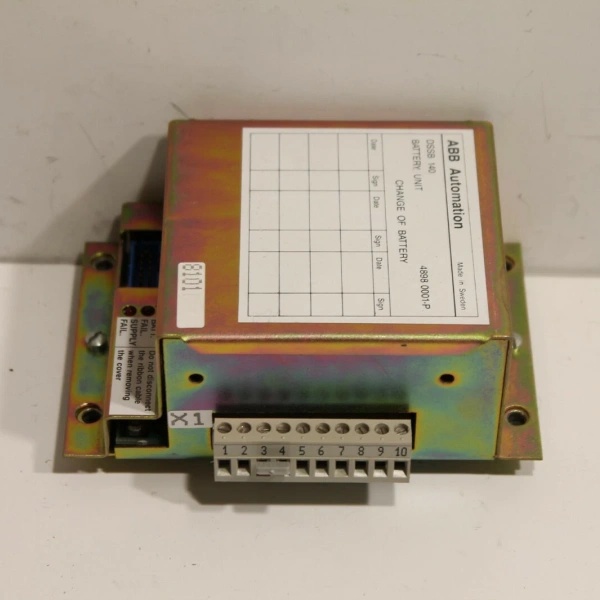

48980001-AGDSSB170: Product Overview

The ABB 48980001-AGDSSB170 is a digital output I/O module from ABB’s DSSB170 series, designed for integration with ABB’s AC 800M distributed control system (DCS). As a critical component of the AC 800M ecosystem, it acts as an interface between the DCS controller and field devices, enabling real-time control of industrial processes (e.g., motor start/stop, valve actuation).

Role in Automation Systems:

Positioned as a “field output interface” in the AC 800M architecture, the 48980001-AGDSSB170 performs two primary functions:

-

Signal Transmission: Receives digital control signals from the AC 800M controller and transmits them to field devices (e.g., relays, solenoids) to execute actions (e.g., starting a motor).

-

Electrical Isolation: Provides galvanic isolation between the controller and field devices, preventing ground loops and voltage spikes from damaging sensitive electronics.

Core Functionality:

-

16-Channel Digital Output: Supports 16 independent digital output channels, each capable of driving 24 V DC devices (0.5 A per channel).

-

Processor-Based Control: Uses an 80386EX processor (25 MHz) to handle signal processing and communication, ensuring reliable operation in harsh industrial environments.

-

Hot-Swappable Design: Allows for replacement without shutting down the system, minimizing downtime during maintenance (critical for 24/7 operations like power generation or chemical processing).

Platform Benefits (AC 800M Series):

The 48980001-AGDSSB170 leverages ABB’s AC 800M platform, which is renowned for:

-

Scalability: Supports expansion with additional I/O modules (e.g., analog input/output) to accommodate growing operational needs.

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in harsh environments (e.g., high temperature, vibration).

-

Integration: Seamlessly integrates with ABB’s other AC 800M components (e.g., controllers, power supplies), reducing setup time and effort.

ABB 48980001-AGDSSB170

Technical Specifications

Model Number: 48980001-AGDSSB170

Manufacturer: ABB

Product Type: Digital Output I/O Module

-

Processor: 80386EX (25 MHz)

-

I/O Channels: 16 digital output (24 V DC, 0.5 A per channel)

-

Voltage Rating: 120 V AC (nominal)

-

Current Consumption: 3.1 A (max)

-

Communication Interface: ModuleBus (compatible with AC 800M controller)

-

Operating Temperature: 0°C to +65°C (32°F to 149°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5–95% non-condensing

-

Dimensions (W×H×D): 25 mm × 32 mm × 65 mm (0.98 in × 1.26 in × 2.56 in)

-

Weight: 0.13 kg (0.29 lbs)

-

Certifications: CE, UL (inferred from ABB industrial product standards)

Core Features & Customer Value

1. Reliable Digital Output Control:

The 48980001-AGDSSB170’s 16 digital output channels provide reliable control of field devices, ensuring that industrial processes (e.g., motor start/stop) are executed accurately. For example, in a chemical plant, the module can control the start/stop of a pump, ensuring consistent flow rates.

2. Hot-Swappable Design for Minimal Downtime:

The module’s hot-swappable design allows technicians to replace faulty modules without shutting down the system. In a power plant, this means that maintenance can be performed during operation, avoiding costly unplanned downtime.

3. Seamless Integration with AC 800M:

Designed specifically for ABB’s AC 800M controller, the 48980001-AGDSSB170 integrates seamlessly with the DCS, reducing setup time and effort. This compatibility ensures that customers can leverage their existing AC 800M infrastructure, reducing costs and complexity.

4. Robust Construction for Harsh Environments:

The module’s industrial-grade design (e.g., rugged housing, wide temperature range) ensures reliable operation in harsh environments. In a steel mill, the module can withstand high temperatures and vibration, maintaining communication with the AC 800M controller.

ABB 48980001-AGDSSB170

Typical Applications

The ABB 48980001-AGDSSB170 is widely used in industries requiring reliable digital output control for process automation:

-

Chemical Processing:

-

Controls the start/stop of pumps and valves in chemical reactors, ensuring consistent process conditions.

-

Example: In a petrochemical refinery, the module controls the start/stop of a pump that delivers crude oil to a distillation column, maintaining optimal flow rates.

-

-

Power Generation:

-

Controls auxiliary equipment (e.g., cooling fans, lubricating pumps) in power plants, ensuring reliable operation of turbines and generators.

-

Example: In a thermal power plant, the module starts a cooling fan when the turbine temperature exceeds a threshold, preventing overheating.

-

-

Manufacturing:

-

Controls conveyor belts and robotic arms in automotive assembly plants, enabling synchronized operation.

-

Example: In an automotive factory, the module controls the start/stop of a conveyor belt, ensuring that car parts are delivered to the assembly line in time.

-