Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 500BIO01 1MRB150005R1J |

| Manufacturer | ABB |

| Product category | Digital input module (part of AC500 PLC system) |

| Number of channels | 8 digital inputs |

| Input type | 24 VDC sinking/sourcing (configurable) |

| Input voltage range | 15 – 30 VDC |

| Input current | 3 mA at 24 VDC (typical) |

| Response time | <1 ms (standard); <0.1 ms (fast mode) |

| Isolation | 500 VAC channel-to-backplane; 250 VAC channel-to-channel |

| Operating temperature | -25°C to +70°C |

| Storage temperature | -40°C to +85°C |

| Humidity tolerance | 5 – 95% RH (non-condensing) |

| Mounting type | DIN rail (35mm) with backplane connection |

| Dimensions | 100mm x 160mm x 60mm |

| Certifications | CE, UL, cUL, ATEX, IECEx |

| Communication | Integrated with AC500 backplane |

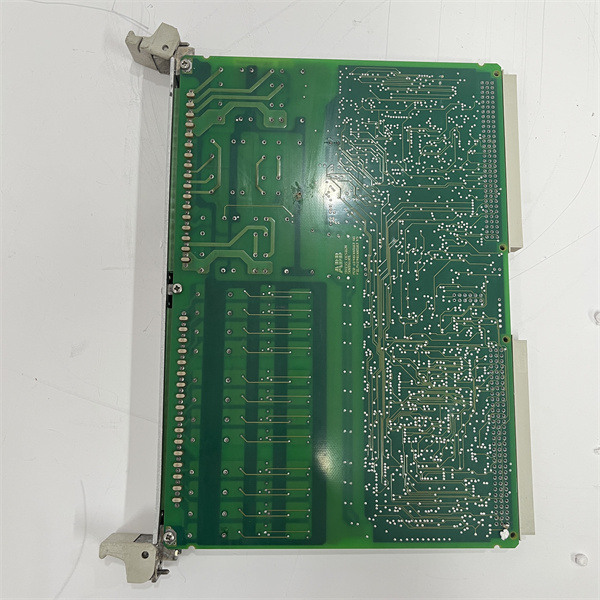

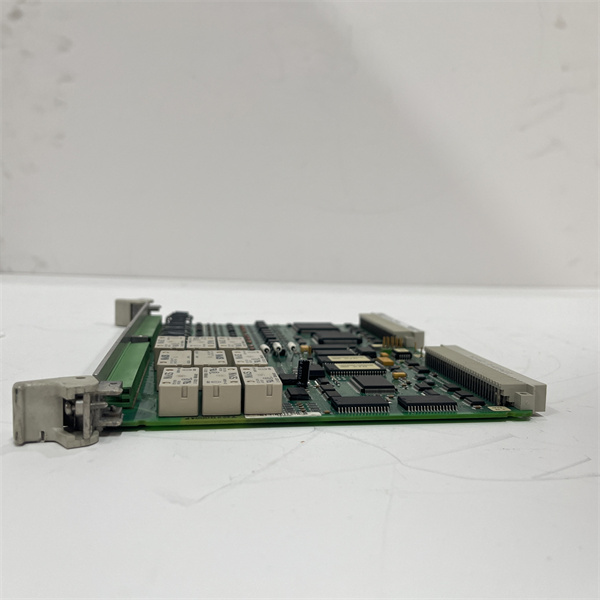

ABB 500BIO01 1MRB150005R1J

Product introduction

The ABB 500BIO01 1MRB150005R1J is a high-performance digital input module designed as part of ABB’s AC500 programmable logic controller (PLC) system, serving as a critical interface between field devices and the control system. This module is engineered to reliably collect digital signals from sensors, switches, and other industrial devices, converting them into data that the PLC can process for real-time decision-making.

With 8 configurable channels supporting both sinking and sourcing inputs, the ABB 500BIO01 1MRB150005R1J offers exceptional flexibility for diverse industrial environments. Its ability to operate across a wide voltage range (15-30 VDC) ensures compatibility with various field devices, while its fast response time makes it suitable for time-critical applications. As a key component of the AC500 system, the ABB 500BIO01 1MRB150005R1J enables seamless integration, ensuring accurate and timely data acquisition to optimize industrial processes and enhance system reliability.

Core advantages and technical highlights

Rapid response capability: The ABB 500BIO01 1MRB150005R1J delivers exceptional response times, with standard mode at less than 1 ms and fast mode at under 0.1 ms. This speed is crucial in high-speed manufacturing processes, such as automotive assembly lines or packaging machinery, where detecting rapid changes in sensor status—like a jammed conveyor or a misaligned part—can prevent equipment damage and production delays.

Flexible configuration: Supporting both sinking and sourcing input types, the ABB 500BIO01 1MRB150005R1J eliminates the need for separate modules for different sensor types. This versatility simplifies inventory management and reduces installation complexity, as the same module can connect to proximity sensors, limit switches, and photoelectric sensors regardless of their output configuration. The 15-30 VDC input range further enhances compatibility with legacy and modern devices.

Robust isolation: Equipped with 500 VAC isolation between channels and the backplane, plus 250 VAC between individual channels, the ABB 500BIO01 1MRB150005R1J protects the PLC system from electrical noise and voltage spikes common in industrial environments. This isolation prevents signal interference from nearby motors, welders, or high-voltage equipment, ensuring stable operation in harsh settings like steel mills or chemical plants.

Wide environmental tolerance: Operating reliably from -25°C to +70°C, the ABB 500BIO01 1MRB150005R1J thrives in extreme conditions, from cold storage facilities to hot industrial ovens. Its resistance to high humidity (5-95% non-condensing) makes it suitable for food processing plants or outdoor installations, minimizing downtime due to environmental factors.

Typical application scenarios

In automotive manufacturing, the ABB 500BIO01 1MRB150005R1J is used to monitor the status of robotic welding cells. It collects signals from limit switches indicating part presence, photoelectric sensors detecting proper fixture alignment, and emergency stop buttons. The module’s fast response time ensures that the PLC can immediately halt operations if a safety breach is detected, protecting workers and preventing costly damage to robots or vehicle components.

Within water and wastewater treatment plants, the ABB 500BIO01 1MRB150005R1J connects to float switches, pressure sensors, and valve position indicators. It relays critical status data—such as high water levels in tanks or valve failure—to the AC500 PLC, enabling automated responses like activating pumps or triggering alarms. Its wide temperature tolerance allows reliable operation in outdoor pump stations, even in freezing or scorching conditions.

In pharmaceutical manufacturing, the ABB 500BIO01 1MRB150005R1J plays a key role in cleanroom automation. It monitors door interlocks, air pressure sensors, and equipment run-status signals, ensuring strict adherence to GMP (Good Manufacturing Practice) standards. The module’s isolation features prevent electrical interference from affecting sensitive equipment, maintaining the integrity of sterile production environments.

ABB 500BIO01 1MRB150005R1J

Related model recommendations

ABB 500BIO02 1MRB150006R1J: A 16-channel variant of the ABB 500BIO01 1MRB150005R1J, ideal for larger systems requiring more input points, such as warehouse automation or bulk material handling.

ABB 500BO11 1MRB150011R1J: A digital output module that pairs with the ABB 500BIO01 1MRB150005R1J to complete the I/O loop, controlling actuators, valves, and alarms based on input data.

ABB AC500-eCo PM554-R: The core PLC controller in the AC500 system, which processes data from the ABB 500BIO01 1MRB150005R1J and executes control logic.

ABB 500AI01 1MRB150002R1J: An analog input module that complements the ABB 500BIO01 1MRB150005R1J in systems requiring both digital and analog data, such as temperature or flow monitoring.

ABB 500DC01 1MRB150020R1J: A power supply module for the AC500 system, providing stable 24 VDC power to the ABB 500BIO01 1MRB150005R1J and other I/O modules.

ABB CI520 1MRB150073R1J: A communication interface module that enables the AC500 system—including the ABB 500BIO01 1MRB150005R1J—to connect to Ethernet networks for remote monitoring and control.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB 500BIO01 1MRB150005R1J, ensure the AC500 backplane is properly mounted on a 35mm DIN rail and powered off. Verify the ambient temperature is within -25°C to +70°C and humidity is 5-95% non-condensing. Gather tools: screwdriver, wire strippers, and a multimeter. Check that field wiring uses twisted-pair cables to reduce noise, and confirm the 24 VDC power supply is stable and fused. Align the module with the backplane connectors, ensuring no debris blocks the connection.

Maintenance suggestions: Inspect the ABB 500BIO01 1MRB150005R1J quarterly for loose wiring or dust accumulation; use compressed air to clean vents. Test input channels annually by connecting a known 24 VDC signal and verifying PLC recognition. Check for channel-to-channel isolation using a megohmmeter to ensure values exceed 100 MΩ at 500 VDC. If a channel fails, first check wiring and sensors before replacing the module. Power down the backplane before removing or inserting the module to prevent damage to the PLC system.

Service and guarantee commitment

The ABB 500BIO01 1MRB150005R1J comes with a 24-month warranty from the purchase date, covering manufacturing defects and ensuring compliance with published specifications. ABB guarantees replacement of faulty modules within 48 hours for critical applications, minimizing downtime.

Technical support includes access to ABB’s global engineering team via phone and email, along with online resources like installation manuals, wiring diagrams, and troubleshooting guides. Customers can also utilize ABB’s local service centers for on-site assistance. Optional extended service contracts offer preventive maintenance, calibration checks, and priority support, ensuring the ABB 500BIO01 1MRB150005R1J delivers reliable performance throughout its 10-year design lifespan.