Description

Detailed parameter table

| Parameter name | Parameter value |

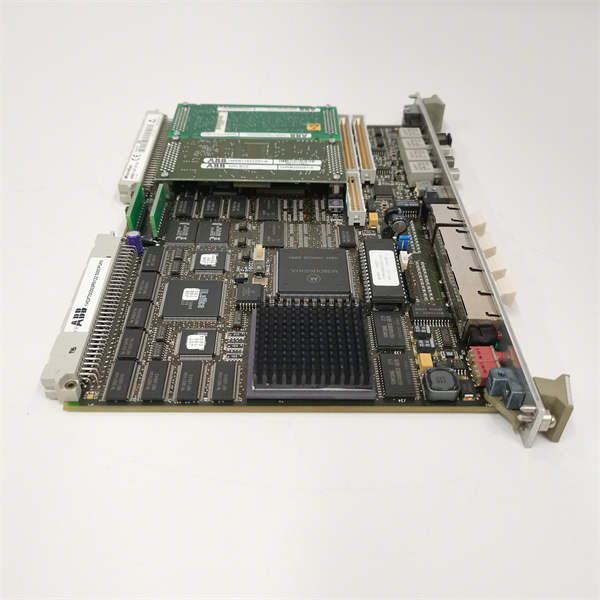

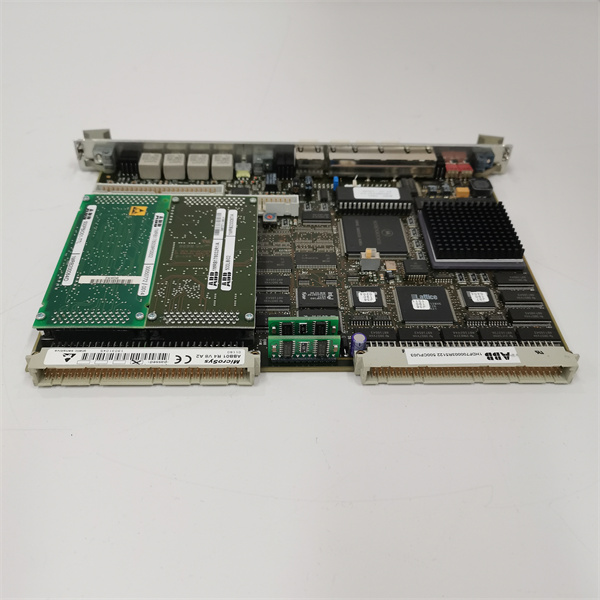

| Product model | 500CPU03 1HDF700003R5122 |

| Manufacturer | ABB |

| Product category | PLC central processing unit |

| Processor | 32-bit RISC, 800 MHz |

| Memory | 128 MB RAM, 256 MB flash |

| Operating system | Real-time operating system (RTOS) |

| Programming languages | IEC 61131-3 (LD, FBD, ST, IL, SCL) |

| Communication interfaces | 2 x Ethernet (10/100/1000 Mbps), 1 x RS-485 |

| Supported protocols | Modbus TCP/IP, Profibus DP, Ethernet/IP |

| I/O capacity | Up to 8,192 digital points; 2,048 analog points |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 12 W |

| Operating temperature range | -25°C to +60°C (-13°F to +140°F) |

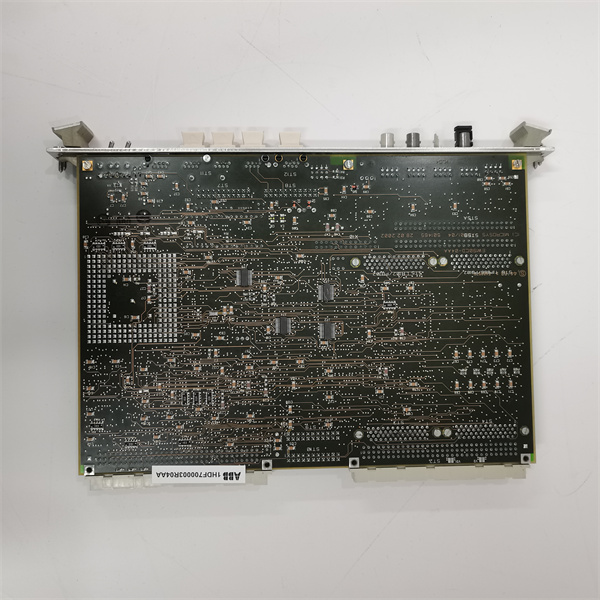

| Dimensions (LxWxH) | 100 mm x 160 mm x 120 mm (3.94 in x 6.30 in x 4.72 in) |

| Protection rating | IP20 |

| Compatibility | ABB AC500 PLC system, S500 I/O modules |

| Mounting type | DIN rail mounting (35 mm) |

| Certification | IEC 61131-2, CE, UL, ATEX, IECEx |

ABB 500CPU03 1HDF700003R5122

Product introduction

The 500CPU03 1HDF700003R5122 is a high-performance PLC central processing unit from ABB, serving as the core of the AC500 PLC system. This CPU is engineered to handle complex automation tasks with precision, integrating powerful processing capabilities with flexible communication options to drive industrial control systems efficiently.

500CPU03 1HDF700003R5122 acts as the “brain” of automation setups, executing control logic, processing real-time data from connected I/O modules, and coordinating with human-machine interfaces (HMIs) and supervisory systems. Its 800 MHz RISC processor and ample memory (128 MB RAM, 256 MB flash) enable rapid execution of complex algorithms, making it suitable for medium to large-scale industrial applications. Whether deployed in manufacturing lines, water treatment plants, or material handling systems, 500CPU03 1HDF700003R5122 ensures reliable operation, fast response times, and seamless integration with existing infrastructure, laying the foundation for efficient and intelligent automation.

Core advantages and technical highlights

High processing efficiency: Equipped with an 800 MHz 32-bit RISC processor, 500CPU03 1HDF700003R5122 delivers exceptional processing speed, executing up to 100,000 instructions per millisecond. This performance ensures quick response to dynamic process changes—critical in applications like high-speed packaging lines or precision assembly stations where even minor delays can impact productivity. The CPU’s multi-tasking capability allows simultaneous execution of control logic, data logging, and communication tasks without performance degradation.

Flexible connectivity: 500CPU03 1HDF700003R5122 features dual Gigabit Ethernet ports and an RS-485 interface, supporting a range of industrial protocols including Modbus TCP/IP, Profibus DP, and Ethernet/IP. This versatility enables seamless integration with sensors, actuators, drives, HMIs, and enterprise systems (such as MES or ERP). The Ethernet ports support ring topologies with redundancy, ensuring uninterrupted communication in mission-critical environments where network downtime is costly.

Scalable I/O capacity: With support for up to 8,192 digital points and 2,048 analog points, 500CPU03 1HDF700003R5122 adapts to growing automation needs. It works seamlessly with ABB’s S500 I/O modules (digital, analog, and specialty modules), allowing users to expand systems incrementally without replacing the CPU. This scalability is ideal for plants undergoing expansion or modernization, reducing long-term investment costs.

Robust reliability: Designed for harsh industrial environments, 500CPU03 1HDF700003R5122 operates reliably across a wide temperature range (-25°C to +60°C) and resists vibration, electromagnetic interference (EMI), and voltage fluctuations. Its flash memory retains program data during power outages, eliminating the need for backup batteries and reducing maintenance. The CPU also includes built-in diagnostics that alert operators to faults in I/O modules or communication links, enabling proactive troubleshooting.

Typical application scenarios

In automotive manufacturing, 500CPU03 1HDF700003R5122 controls robotic assembly lines, coordinating welding robots, conveyor systems, and quality inspection stations. Its fast processing speed ensures synchronized movement of robots and conveyors, with cycle times as low as 10 ms, while Ethernet/IP connectivity enables real-time data exchange with plant MES systems for production tracking. The CPU’s redundancy features prevent line shutdowns during network or power disruptions, maintaining high throughput.

Within water and wastewater treatment plants, 500CPU03 1HDF700003R5122 manages pumping stations, filtration systems, and chemical dosing processes. It processes data from flow meters, pH sensors, and level transmitters (via analog I/O modules), executing PID control loops to maintain water quality parameters. Modbus TCP/IP communication allows remote monitoring via SCADA systems, while the CPU’s robust design withstands humid conditions and electrical noise from pumps and valves.

In logistics and material handling, 500CPU03 1HDF700003R5122 oversees automated storage and retrieval systems (AS/RS) in warehouses. It coordinates crane movements, conveyor sorting, and inventory tracking, using Profibus DP to communicate with motor drives and position sensors. The CPU’s large I/O capacity supports hundreds of limit switches and photoelectric sensors, ensuring accurate item handling and minimizing errors in order fulfillment.

ABB 500CPU03 1HDF700003R5122

Related model recommendations

500CPU01 1HDF700001R5121: Entry-level CPU in the AC500 series, offering lower processing power than 500CPU03 1HDF700003R5122 for small-scale applications with basic control needs.

500CPU04 1HDF700004R5123: High-end variant with a 1.2 GHz processor and expanded memory, ideal for large-scale systems requiring advanced algorithms or heavy data logging, complementing 500CPU03 1HDF700003R5122 in distributed setups.

DI521: Digital input module compatible with 500CPU03 1HDF700003R5122, providing 16 channels for connecting proximity sensors and emergency stops in industrial machinery.

AO523: Analog output module that pairs with 500CPU03 1HDF700003R5122, offering 4 channels for 4-20 mA signals to control variable speed drives and proportional valves.

CM578-ETH: Ethernet communication module that extends 500CPU03 1HDF700003R5122’s connectivity to additional networks, supporting protocols like PROFINET for integration with third-party devices.

PM590: Compact PLC from ABB’s AC500-eCo series, working alongside 500CPU03 1HDF700003R5122 in distributed systems to handle localized control tasks, reducing processing load on the main CPU.

Panel 800: HMI panel designed to interface with 500CPU03 1HDF700003R5122, providing operators with real-time visualization and manual control of automation processes.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 500CPU03 1HDF700003R5122, ensure the DIN rail is securely mounted in a dust-free, vibration-free enclosure with ambient temperature between -25°C and +60°C. Use a torque wrench (set to 0.8 Nm) to fasten the CPU, ensuring a stable connection. Verify the 24 V DC power supply is regulated, grounded, and protected by a 2A fuse. Connect Ethernet cables (Cat 5e or higher) for network communication, and route signal cables separately from power cables to minimize EMI. Allow 30 mm clearance around the CPU for ventilation, preventing overheating during extended operation.

Maintenance suggestions: For 500CPU03 1HDF700003R5122, perform monthly checks of status LEDs to monitor power, communication, and fault conditions. Back up program data to a secure storage device quarterly using ABB’s Automation Builder software. Clean dust from ventilation slots annually with compressed air (max 5 bar) to maintain cooling efficiency. Inspect Ethernet and RS-485 connections quarterly for tightness and corrosion, reterminating if necessary. If the CPU experiences communication errors, check network settings and cable integrity; update firmware annually via Automation Builder to access new features and security patches. Use only ABB-approved spare parts for replacements to preserve system compatibility.

Service and guarantee commitment

500CPU03 1HDF700003R5122 is backed by a 5-year warranty from ABB, covering manufacturing defects and ensuring compliance with performance specifications under normal operating conditions. ABB’s global technical support team provides 24/7 assistance for programming, troubleshooting, and system integration, with critical issues addressed within 4 hours.

We offer on-site commissioning services, where certified engineers configure the CPU, optimize control logic, and verify communication with I/O modules and HMIs. Extended warranty options (up to 7 years) include annual preventive maintenance, firmware updates, and priority technical support. In the event of a fault, ABB maintains regional stock of 500CPU03 1HDF700003R5122 units, enabling next-day delivery to minimize downtime. All repairs use genuine ABB components, ensuring the CPU retains its original processing performance and protocol compatibility. This commitment reflects ABB’s confidence in the reliability of 500CPU03 1HDF700003R5122 and its dedication to supporting seamless industrial operations.