Description

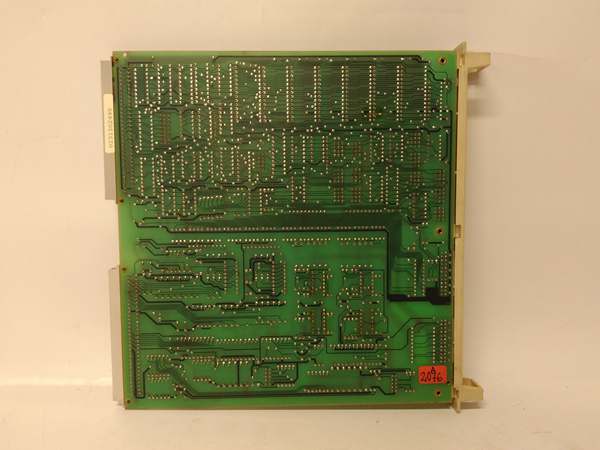

ABB 5716-0001-GF DSDP150

-

Model Number: 5716-0001-GF DSDP150 -

Manufacturer: ABB -

Product Type: Distributed System Diagnostic Panel -

Protocol Support: Modbus TCP, IEC 61850-8-1 (GOOSE), DNP3.0 -

Number of Channels: 16 (8 analog, 8 digital; software-configurable) -

Signal Types: Analog (4-20mA, 0-10V DC), Digital (24V DC sinking/sourcing) -

Isolation Voltage: 500V AC (channel-to-bus, channel-to-channel) -

Operating Temperature: -25°C to +60°C -

Humidity Range: 5% to 95% non-condensing -

Power Supply: 24V DC (from DCS/SIS rack backplane, 18-32V DC range) -

Power Consumption: 3.0W (typical, all channels active) -

Diagnostic Coverage: Open circuit, short circuit, overrange, noise (>50mVpp), communication timeout -

Resolution: 16-bit (analog), 1ms (digital timestamping) -

Dimensions: 45mm x 128mm x 115mm (width x height x depth, fits S800 I/O rack) -

Weight: 0.3kg -

Certifications: CE, UL, cULus, RoHS, IEC 61000-6-2 (EMC) ABB 5716-0001-GF DSDP150