Description

Detailed parameter table

| Parameter name | Parameter value |

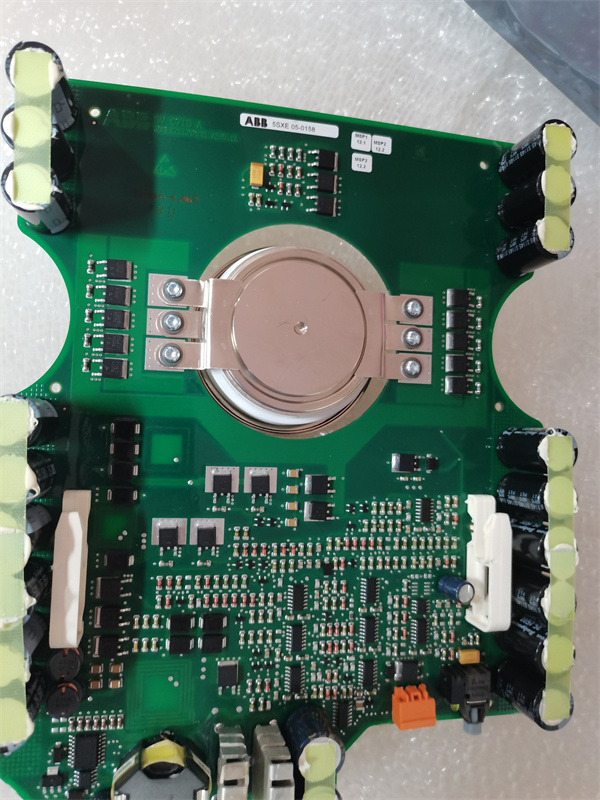

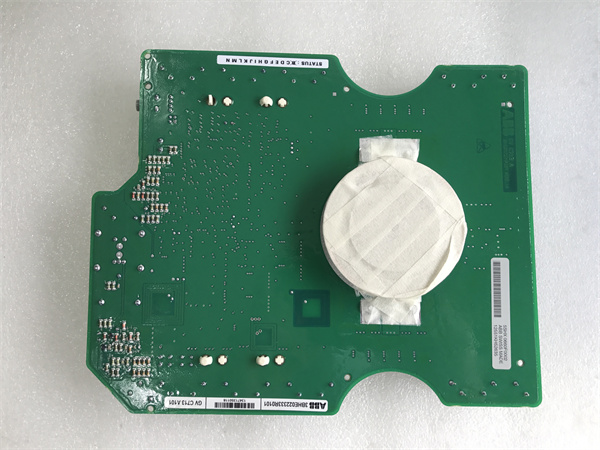

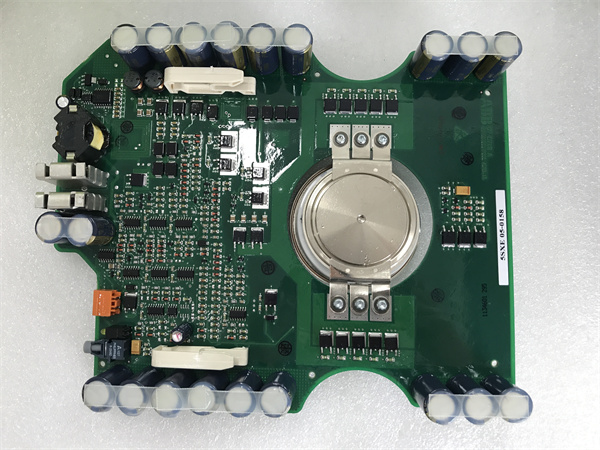

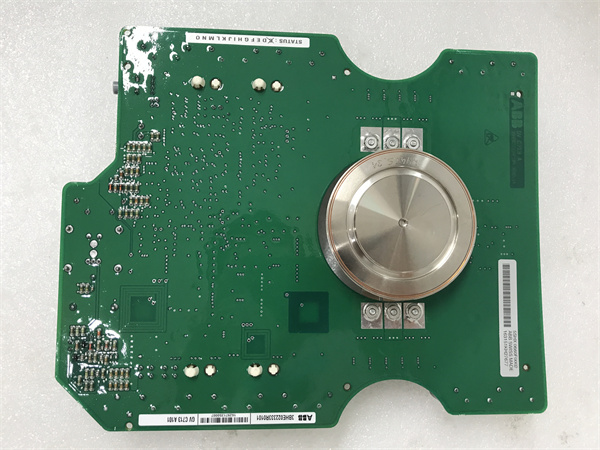

| Product model | 5SHX0660F0002 |

| Manufacturer | ABB |

| Product category | IGBT module (Insulated Gate Bipolar Transistor) |

| Rated collector current (Ic) | 600 A (at 25°C, DC) |

| Collector-emitter voltage (Vces) | 1700 V |

| Gate-emitter voltage (Vges) | ±20 V |

| Maximum power dissipation (Ptot) | 2400 W (at 25°C, heatsink temperature) |

| Switching frequency | Up to 20 kHz |

| Junction temperature range (Tj) | -40°C to +150°C |

| Isolation voltage (Viso) | 6000 Vrms (1 min) |

| Dimensions (LxWxH) | 190 mm x 140 mm x 30 mm (7.48 in x 5.51 in x 1.18 in) |

| Mounting type | Screw mounting (M6 bolts) |

| Package type | Press-fit terminal, module with baseplate |

| Certification | IEC 60747, UL 1557, CE |

ABB 5SHX0660F0002

Product introduction

The ABB 5SHX0660F0002 is a high-power IGBT module designed for demanding industrial applications, part of ABB’s robust portfolio of power semiconductor components. This module integrates insulated gate bipolar transistors (IGBTs) with freewheeling diodes, delivering efficient power conversion in high-voltage, high-current systems.

ABB 5SHX0660F0002 serves as a critical switching component in power electronic converters, enabling precise control of electrical power in applications such as variable speed drives, renewable energy inverters, and industrial power supplies. With a rated voltage of 1700 V and current of 600 A, it balances high power handling with fast switching capabilities, making it suitable for medium to large-scale industrial systems. Whether deployed in motor drives, grid-tied inverters, or traction systems, ABB 5SHX0660F0002 ensures reliable performance, high efficiency, and robust operation in harsh electrical environments.

Core advantages and technical highlights

High power density: ABB 5SHX0660F0002 combines a 600 A current rating with a compact form factor (190 mm x 140 mm), delivering exceptional power density that reduces the size of power converter assemblies. This space efficiency is critical in applications with limited cabinet space, such as industrial drives and locomotive power systems.

Efficient switching performance: The module’s optimized IGBT chip design enables fast switching (up to 20 kHz) with low conduction and switching losses. This efficiency minimizes energy waste, reduces heat generation, and lowers cooling system requirements, contributing to overall system sustainability.

Robust thermal management: ABB 5SHX0660F0002 features a direct copper bond (DCB) substrate and a thermally conductive baseplate, ensuring efficient heat transfer from the semiconductor chips to the heatsink. Its wide junction temperature range (-40°C to +150°C) allows operation in high-temperature environments without performance degradation, enhancing system reliability.

Enhanced ruggedness: With an isolation voltage of 6000 Vrms and built-in protection against overcurrent and short circuits, ABB 5SHX0660F0002 withstands electrical stress in demanding applications. Its press-fit terminals provide secure electrical connections with minimal contact resistance, reducing the risk of failure due to vibration or thermal cycling.

Typical application scenarios

In industrial variable speed drives (VSDs) for large motors (500 kW to 2 MW), ABB 5SHX0660F0002 serves as the primary switching device in the inverter stage, converting DC bus voltage to variable-frequency AC power. Its high current handling and fast switching enable precise motor speed control, improving energy efficiency in applications such as centrifugal pumps, fans, and compressors in manufacturing plants.

Within renewable energy systems, particularly solar inverters and wind turbine converters, ABB 5SHX0660F0002 facilitates grid-tie power conversion. Its 1700 V rating accommodates the high DC voltages from solar arrays or wind generators, while its efficient switching minimizes power losses, maximizing energy harvest. The module’s rugged design ensures reliable operation in outdoor environments with temperature fluctuations.

In traction systems for electric locomotives and high-speed trains, ABB 5SHX0660F0002 controls the traction motor drives, handling the high currents and voltages required for propulsion. Its ability to withstand vibration and wide temperature ranges (-40°C to +150°C) ensures consistent performance in harsh railway environments, while its fast switching enables smooth acceleration and deceleration.

ABB 5SHX0660F0002

Related model recommendations

ABB 5SHX0450F0002: A lower-current variant (450 A, 1700 V) of ABB 5SHX0660F0002, suitable for medium-power applications (300 kW to 1 MW) such as industrial pumps and small wind turbines.

ABB 5SHX1060F0002: A higher-current model (1000 A, 1700 V) than ABB 5SHX0660F0002, ideal for large-scale systems like utility-scale inverters and locomotive traction drives.

ABB 5SNA 1200E170300: IGBT module with similar voltage rating (1700 V) but different packaging, offering compatibility with alternative system designs.

ABB RDCO-03C: Gate driver board specifically designed for ABB 5SHX0660F0002, providing precise control signals and overcurrent protection.

ABB SKiiP® 23AC126V1: Integrated power module that combines ABB 5SHX0660F0002-equivalent IGBTs with drivers and cooling, simplifying system integration.

ABB THM600: Temperature monitoring module that pairs with ABB 5SHX0660F0002 to track junction temperatures, preventing overheating in high-load conditions.

ABB CSS100: Circuit breaker accessory for systems using ABB 5SHX0660F0002, providing overcurrent protection at the system level.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing ABB 5SHX0660F0002, ensure the heatsink is clean, flat, and properly sized to dissipate 2400 W of power (recommended thermal resistance ≤0.05 K/W). Required tools include a torque wrench (set to 8 Nm for mounting bolts), thermal paste (ABB-recommended type), and an insulation tester. Degrease the baseplate and heatsink mating surfaces, then apply a thin, uniform layer of thermal paste to ensure optimal heat transfer. Verify that the mounting surface is free of burrs or scratches that could compromise thermal contact.

Maintenance suggestions: For ABB 5SHX0660F0002, monitor junction temperature during operation using built-in thermistors or external sensors—ensure Tj does not exceed +150°C. Inspect terminal connections quarterly for tightness and signs of corrosion, retorquing if necessary to prevent increased contact resistance. Clean the heatsink fins annually to remove dust and debris, which can reduce cooling efficiency. If the module exhibits increased voltage drop or switching losses, perform a visual inspection for cracked DCB substrates or damaged terminals. Replace ABB 5SHX0660F0002 if signs of overheating (discoloration) or electrical damage are detected, using only genuine ABB replacements to maintain performance.

Service and guarantee commitment

ABB 5SHX0660F0002 is backed by a 2-year warranty from the date of installation, covering manufacturing defects and performance issues under normal operating conditions. ABB’s technical support team provides specialized assistance for thermal design, gate driver integration, and troubleshooting, with response times guaranteed within 12 hours for critical inquiries.

We offer application engineering services to optimize the integration of ABB 5SHX0660F0002 into power converter designs, including thermal simulation and reliability analysis. Extended warranty options up to 5 years are available, including annual performance testing. In the event of a fault, ABB guarantees a 72-hour turnaround for failure analysis, with replacement modules available for next-day delivery to minimize system downtime. All replacements use genuine ABB components, ensuring ABB 5SHX0660F0002 maintains its original power handling and switching characteristics.