Description

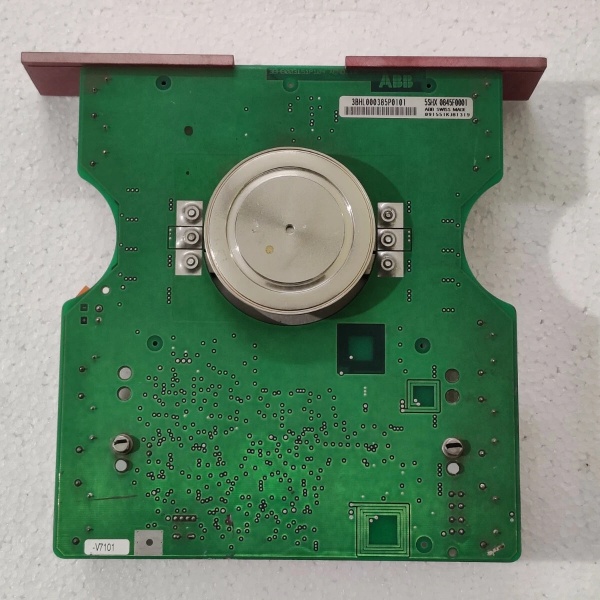

ABB 5SHX0845F0001

-

Model Number: 5SHX0845F0001 -

Manufacturer: ABB -

Product Type: IGBT Power Module -

Blocking Voltage: 4500V (Vces) -

Continuous Collector Current: 1500A (Tc = 80°C) -

Switching Frequency: Up to 20kHz (optimized for hard-switching applications) -

Encapsulation: Press-pack (direct copper bonding, no bond wires) -

Internal Structure: IGBT chip + freewheeling diode (anti-parallel) -

Thermal Resistance: Rth(j-c) = 0.025°C/W (junction-to-case) -

Operating Temperature: -40°C to +125°C (case temperature, Tc) -

Isolation Voltage: 10kV AC (1 minute, case-to-heatsink) -

Gate Drive Voltage: +15V/-15V (standard IGBT driver interface) -

Protection Features: Overcurrent, overtemperature, and short-circuit withstand (10μs) -

Certifications: IEC 60747-9, UL 1557, RoHS

ABB 5SHX0845F0001