Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | AI880-1 |

| Manufacturer | ABB |

| Product category | High-density analog input module |

| Number of channels | 8 (isolated, individually configurable) |

| Input signal types | 4-20 mA, 0-20 mA, 0-10 V DC, thermocouple (J/K/T/E/R/S/B), RTD (Pt100, Pt1000) |

| Measurement accuracy | ±0.03% FS (4-20 mA), ±0.08°C (thermocouple), ±0.05°C (RTD) |

| Sampling rate | 15 Hz per channel (simultaneous) |

| Isolation | Channel-to-channel: 2 kV AC; Channel-to-backplane: 5 kV AC |

| Operating voltage | 24 V DC ±15% (powered via backplane) |

| Power consumption | Max 3.5 W |

| Operating temperature | -40°C to 70°C |

| Protection rating | IP20 |

| Mounting type | Backplane mount (compatible with AC800M/S800 series) |

| Dimensions | 100mm × 160mm × 80mm |

| Certifications | CE, UL, ATEX, IEC 61131-2, IEC 61010-1 |

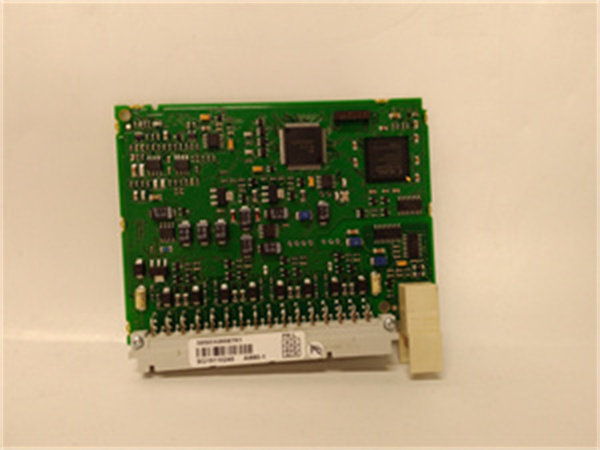

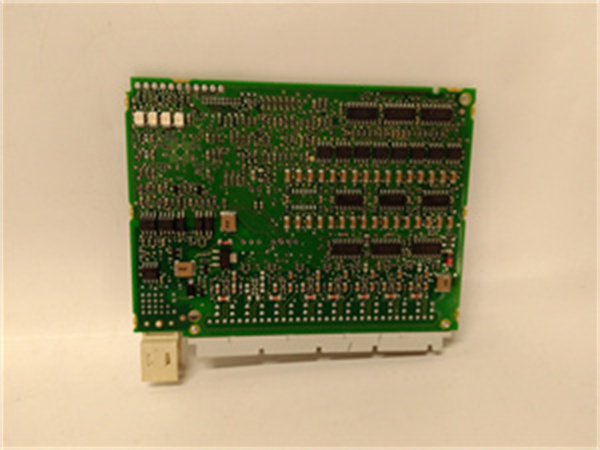

ABB AI880-1

Product introduction

The AI880-1 is a high-performance analog input module from ABB, engineered to convert and process a wide range of continuous physical signals into digital data for industrial control systems. As a key component in ABB’s measurement and control portfolio, this module serves as a critical interface between field sensors (such as pressure transmitters, temperature probes, and flow meters) and central controllers like the 3BHE024577R0101 PPC907BE AMC34 processor module, ensuring accurate data acquisition in complex automation environments.

Unlike standard analog modules, the AI880-1 combines high channel density with robust isolation and flexible configuration, making it ideal for applications where space is limited but precision is essential—from chemical processing plants to renewable energy facilities. Whether deployed in harsh industrial settings or controlled factory environments, this module delivers consistent performance, enabling precise process control and real-time monitoring.

Core advantages and technical highlights

High-density channel configuration: With 8 isolated channels in a compact form factor, the AI880-1 maximizes I/O density, reducing the number of modules needed in control cabinets. In a solar power plant, this allows monitoring of 8 different inverter temperatures (via RTDs) and 8 DC bus voltage sensors (0-10 V) using a single module, saving 30% of backplane space compared to lower-density alternatives. Each channel is individually configurable, eliminating the need for hardware modifications when connecting diverse sensor types.

Exceptional measurement accuracy: The module offers ±0.03% full-scale accuracy for 4-20 mA signals, ensuring precise readings from critical sensors like pressure transmitters in oil refineries. For temperature measurements, its ±0.08°C accuracy with thermocouples and ±0.05°C with RTDs makes it suitable for pharmaceutical batch processing, where maintaining strict temperature ranges is essential for product quality. Low drift (<30 ppm/°C) ensures long-term stability, reducing the need for frequent recalibration.

Robust isolation and noise immunity: Equipped with 2 kV AC channel-to-channel isolation and 5 kV AC isolation from the backplane, the AI880-1 effectively rejects electromagnetic interference (EMI) and ground loops common in industrial environments. In a steel mill, this isolation ensures accurate current measurements from furnace sensors despite nearby high-voltage equipment, preventing measurement errors that could lead to process instability.

Seamless system integration: Designed for compatibility with ABB’s AC800M/S800 backplanes, the AI880-1 integrates seamlessly with communication gateways like the GCC960C103 and power distribution modules such as the PPD513A25-111615. It supports hot swapping, allowing replacement without system shutdown—a critical feature in continuous processes like water treatment. Diagnostic data (including channel faults and signal quality) is transmitted to the controller, enabling predictive maintenance and reducing downtime.

Wide signal compatibility: The module supports a broad range of input signals, including 4-20 mA, 0-20 mA, 0-10 V DC, thermocouples (J/K/T/E/R/S/B), and RTDs (Pt100, Pt1000). In a food and beverage plant, this flexibility allows it to monitor flow rates (4-20 mA), tank levels (0-10 V), and refrigeration temperatures (Pt100) using a single module, simplifying system design and reducing inventory costs.

Typical application scenarios

In a natural gas processing plant, the AI880-1 monitors key parameters of the separation process: including 4 pressure transmitters (4-20 mA), 2 temperature sensors (K-type thermocouples), and 2 level transmitters (0-10 V). Its high accuracy ensures precise control of pressure valves, maximizing gas yield while maintaining safety margins. The module’s isolation protects measurements from noise generated by compressors, ensuring reliable data transmission to the PPC907BE AMC34 processor via the GCC960C103 gateway.

In a wastewater treatment facility, the module processes data from 8 dissolved oxygen sensors (4-20 mA) and pH probes (converted to 4-20 mA) across different treatment stages. Its ability to operate in temperatures up to 70°C allows installation in unconditioned pump rooms, while its low power consumption (3.5 W) reduces the load on the plant’s backup power system. Diagnostic alerts from the module enable maintenance teams to replace faulty sensors before they impact water quality.

ABB AI880-1

Related model recommendations

AO880-1: ABB’s 8-channel analog output module that complements the AI880-1 for control signal generation.

DI880: ABB’s 16-channel digital input module that, when paired with the AI880-1, provides mixed-signal monitoring.

3BHE024577R0101 PPC907BE AMC34: ABB’s processor module that processes data from the AI880-1 for control and analysis.

GCC960C103: ABB’s communication gateway that routes AI880-1 data to distributed control systems.

PPD513A25-111615 3BHE039724R2565: ABB’s power distribution module that supplies stable power to the analog input module.

TB857: ABB’s surge protection terminal block that safeguards the module from voltage transients.

HMI80: ABB’s touchscreen panel that visualizes real-time measurements from the AI880-1, enabling operator monitoring.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the AI880-1 into a compatible S800 backplane using the front-panel screw, torquing to 0.5 Nm. Ensure at least 50mm clearance for ventilation. Connect field sensors using shielded twisted-pair cable (0.5-1 mm²), grounding shields at the module end. For thermocouples, use dedicated thermocouple wire to minimize measurement errors. Required tools include a torque screwdriver, wire strippers, and a calibrated multimeter. Power off the backplane during installation.

Commissioning steps: Use ABB’s Automation Builder software to configure each channel’s signal type, scaling, and filtering. For example, set a 4-20 mA channel to map 4 mA = 0 bar and 20 mA = 100 bar. Perform a calibration check using a precision signal generator, verifying accuracy across 0%, 50%, and 100% of full scale. Test RTD channels with a reference temperature simulator to confirm ±0.05°C accuracy. Save configurations to non-volatile memory and verify data transmission to the controller.

Maintenance suggestions: Inspect the module quarterly for loose connections, dust accumulation, and LED status (power: green, channel faults: red). Clean ventilation slots with compressed air. Calibrate annually using traceable standards to maintain measurement accuracy—critical for regulated industries like chemicals. Check isolation resistance yearly with a megohmmeter (minimum 100 MΩ at 500 V DC). If channels exhibit drift or failure, verify sensor wiring and signal integrity before replacing the module with an ABB-certified unit.

Service and guarantee commitment

The AI880-1 comes with a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with published accuracy specifications. ABB guarantees technical support response within 4 hours for critical applications, with on-site calibration services available in 72 hours for qualified customers. The module includes a free initial calibration certificate traceable to international standards. Extended service contracts offer annual calibration, preventive maintenance, and priority support, ensuring the module maintains measurement integrity throughout its 15-year design lifespan. Customers receive dedicated online resources, including wiring diagrams, calibration procedures, and application notes specific to this model.