Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | AIM0006 2RCA021397A0001F |

| Manufacturer | ABB |

| Product category | Analog input module (Advant Controller series) |

| Input channels | 8 differential analog inputs |

| Input type | 4-20 mA DC, 0-10 V DC (configurable per channel) |

| Resolution | 16-bit |

| Accuracy | ±0.1% of full scale (4-20 mA), ±0.15% of full scale (0-10 V) |

| Isolation | 2500 VAC (channel to backplane, channel to channel) |

| Sampling rate | 10 samples per second per channel |

| Operating voltage | 24 VDC ±10% |

| Power consumption | Max 8 W |

| Operating temperature | 0°C to 60°C |

| Protection rating | IP20 |

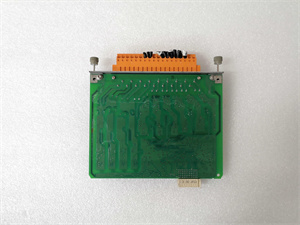

| Dimensions | 100mm × 80mm × 60mm |

| Weight | 0.4kg |

| Certifications | IEC 61131-2, CE, UL, CSA |

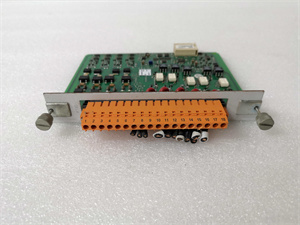

| Mounting type | DIN rail (35mm) with backplane connection |

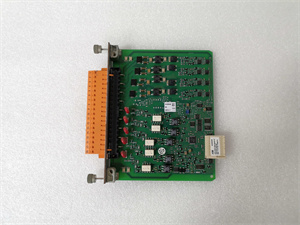

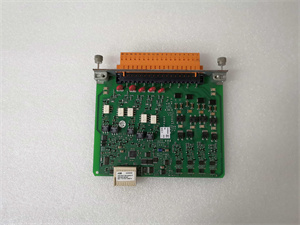

ABB AIM0006 2RCA021397A0001F

Product introduction

The ABB AIM0006 2RCA021397A0001F is a high-precision analog input module designed for seamless integration with ABB’s Advant Controller series, serving as a critical interface for converting continuous physical signals from field devices into digital data for processing. This module excels in capturing and transmitting analog measurements such as pressure, temperature, flow, and level, making it an essential component in process control and monitoring systems across industries.

Featuring 8 configurable differential channels, the ABB AIM0006 2RCA021397A0001F supports both 4-20 mA DC current signals and 0-10 V DC voltage signals, allowing flexible connection to a wide range of sensors and transmitters. Its 16-bit resolution and high accuracy ensure that even subtle changes in process variables are detected, providing the controller with reliable data for precise control decisions.

Within automation architectures, the ABB AIM0006 2RCA021397A0001F enhances system performance by enabling real-time monitoring of critical process parameters. Its robust isolation design protects the controller from electrical noise and ground loops, ensuring stable operation in harsh industrial environments. Whether deployed in chemical plants, water treatment facilities, or manufacturing lines, this module delivers consistent performance for maintaining process efficiency and product quality.

Core advantages and technical highlights

High measurement accuracy: The ABB AIM0006 2RCA021397A0001F achieves ±0.1% accuracy for 4-20 mA signals and ±0.15% for 0-10 V signals, ensuring precise capture of process variables. This level of accuracy is critical for applications such as pharmaceutical manufacturing, where tight control of temperature and pressure directly impacts product quality. Its 16-bit resolution allows detection of minute changes (e.g., 0.006 mA increments in a 4-20 mA loop), enabling early identification of process deviations.

Channel-level configurability: Each of the 8 channels on the ABB AIM0006 2RCA021397A0001F can be individually configured for either 4-20 mA or 0-10 V input, providing unmatched flexibility. This allows the module to connect to mixed sensor types—for example, 4-20 mA pressure transmitters and 0-10 V temperature sensors—without requiring separate modules. Configuration is simplified via ABB’s programming software, eliminating the need for hardware jumpers and reducing setup time.

Enhanced noise immunity: With 2500 VAC isolation between channels and from the backplane, the ABB AIM0006 2RCA021397A0001F effectively rejects electromagnetic interference (EMI) and radio frequency interference (RFI) common in industrial environments. This ensures stable measurement even near large motors, variable frequency drives, or high-voltage equipment. Differential input design further minimizes the impact of noise on signal integrity, making it suitable for long cable runs (up to 1000 meters for 4-20 mA signals).

Efficient data acquisition: The module’s 10 samples per second per channel sampling rate balances responsiveness with system load, ensuring timely data delivery without overwhelming the controller. This rate is ideal for most process control applications, providing sufficient granularity to track dynamic changes (e.g., flow rate fluctuations in a pipeline) while maintaining efficient communication with the Advant Controller.

Compact and scalable design: The ABB AIM0006 2RCA021397A0001F‘s compact form factor (100mm × 80mm × 60mm) saves space in control cabinets, while its DIN rail mounting with backplane connection simplifies installation and expansion. Multiple modules can be daisy-chained to increase input capacity, allowing system designers to scale from 8 to hundreds of analog channels as application needs grow.

Typical application scenarios

In chemical processing plants, the ABB AIM0006 2RCA021397A0001F monitors key process variables in reactor vessels, including temperature (via 4-20 mA RTD transmitters), pressure (4-20 mA pressure transducers), and pH levels (0-10 V pH meters). Its high accuracy ensures that reaction conditions stay within tight tolerances, preventing product degradation and ensuring compliance with safety standards. The module’s noise immunity is critical in this environment, where electrical noise from 搅拌器 motors could otherwise distort measurements.

Within water and wastewater treatment facilities, the module tracks flow rates (4-20 mA magnetic flowmeters), chemical dosage levels (0-10 V level sensors), and turbidity (4-20 mA analyzers). Its differential inputs and isolation protect against ground loops caused by wet well pumps and variable frequency drives, ensuring reliable data for optimizing treatment processes and reducing chemical usage. The 8-channel design allows monitoring of multiple treatment stages (e.g., sedimentation, filtration, disinfection) with a single module.

In food and beverage production lines, the ABB AIM0006 2RCA021397A0001F monitors pasteurization temperatures (4-20 mA thermocouple transmitters), filling pressures (0-10 V pressure sensors), and conveyor speed (4-20 mA tachometers). Its accurate measurements ensure compliance with food safety regulations (e.g., maintaining pasteurization temperatures for required durations), while its compact size fits easily in the control panels of space-constrained packaging machinery.

ABB AIM0006 2RCA021397A0001F

Related model recommendations

ABB AOM004 2RCA021398A0001F: A 4-channel analog output module that pairs with the ABB AIM0006 2RCA021397A0001F, providing control signals to valves and actuators.

ABB Advant Controller 410: The main process controller that processes input data from the ABB AIM0006 2RCA021397A0001F and executes control logic.

ABB TU810: A termination unit that simplifies wiring for the ABB AIM0006 2RCA021397A0001F, providing surge protection and easy field connections.

ABB CI801 3BSE022369R1: A communication interface that connects the Advant Controller (with ABB AIM0006 2RCA021397A0001F) to Ethernet-based systems.

ABB TTF300: A 4-20 mA temperature transmitter that converts RTD signals to a format compatible with the ABB AIM0006 2RCA021397A0001F.

ABB 800xA Extension: Software that integrates analog data from the ABB AIM0006 2RCA021397A0001F into ABB’s 800xA DCS for advanced visualization and trending.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB AIM0006 2RCA021397A0001F, ensure the 35mm DIN rail is securely mounted and grounded in a clean, dry control cabinet. Verify the ambient temperature is within 0°C to 60°C and humidity is below 95% RH (non-condensing). Required tools include a torque screwdriver (0.5-0.8 Nm), wire strippers, and a multimeter. Use shielded twisted-pair cables (0.5-1.0 mm²) for analog connections, with shields grounded at both ends to minimize noise. For 4-20 mA signals, ensure loop resistance does not exceed 500 ohms.

Commissioning steps: After physical installation, power on the system and launch ABB’s configuration software to set channel types (4-20 mA or 0-10 V) and scaling parameters (e.g., engineering units like °C or psi). Calibrate each channel using a precision signal generator, verifying that the module’s digital output matches the applied analog input within the specified accuracy range. Test communication with the Advant Controller to ensure data is transmitted correctly, and configure alarm thresholds for out-of-range values.

Maintenance suggestions: Inspect the ABB AIM0006 2RCA021397A0001F quarterly for loose connections, dust accumulation, or signs of corrosion; clean with compressed air if necessary. Verify accuracy annually using a certified calibration tool, adjusting offsets if needed. Monitor module status via the controller—check for communication errors or channel faults. If a channel fails, isolate the issue by testing with a known good signal; replace the module with an ABB-approved unit if faults persist to maintain measurement integrity.

Service and guarantee commitment

The ABB AIM0006 2RCA021397A0001F comes with a 36-month warranty from the date of installation, covering manufacturing defects and ensuring compliance with published accuracy specifications. ABB guarantees replacement of faulty modules within 72 hours for critical applications, minimizing downtime in process control systems.

Technical support includes access to ABB’s global team of automation engineers, available for assistance with configuration, calibration, and troubleshooting. Online resources include detailed wiring diagrams, calibration procedures, and compatibility charts specific to the Advant Controller series. Customers can opt for extended service contracts offering annual preventive maintenance, calibration services, and on-site support, ensuring the module delivers reliable performance throughout its 10-year design lifespan.