Description

Detailed parameter table

| Parameter name | Parameter value |

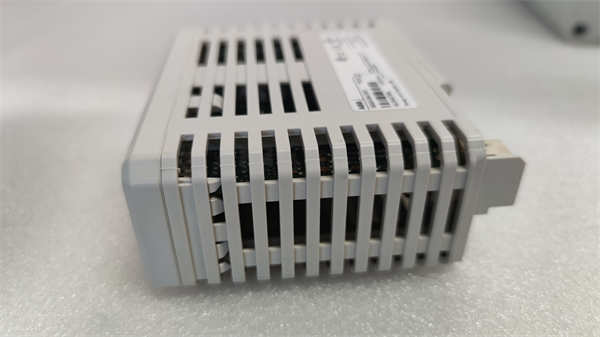

| Product model | AO810V2 |

| Manufacturer | ABB |

| Product category | Analog output module |

| Compatible systems | ABB AC800M controller, S800 I/O system |

| Number of channels | 4 analog output channels |

| Output signal types | 4-20 mA DC, 0-20 mA DC, 0-10 V DC, ±10 V DC |

| Accuracy | ±0.1% of full scale (at 25°C) |

| Resolution | 16 bits |

| Update rate | 100 ms per channel |

| Load capacity | 500 Ω max for current outputs; 10 kΩ min for voltage outputs |

| Operating voltage | 24 V DC ±10% |

| Power consumption | ≤ 4 W |

| Operating temperature | -25°C to +70°C |

| Isolation | 2.5 kV AC (channel-to-channel, channel-to-bus) |

| Dimensions (W×H×D) | 22 mm × 105 mm × 115 mm |

| Installation method | DIN rail mounting via terminal base (e.g., TB820V2) |

| Protection class | IP20 |

| Diagnostic features | LED indicators for power, channel status, and faults |

ABB AO810V2

Product introduction

The AO810V2 is a high-performance analog output module from ABB, designed to convert digital control signals from the AC800M controller into precise analog outputs for industrial actuators and devices. As a key component of the S800 I/O system, it serves as a critical interface between the digital control layer and analog field equipment such as control valves, variable speed drives, and positioners.

Engineered for versatility, the AO810V2 offers 4 independently configurable channels, supporting a range of signal types including 4-20 mA, 0-10 V, and ±10 V. This flexibility allows it to adapt to diverse applications, from regulating flow in chemical processing to adjusting damper positions in HVAC systems. Its robust construction ensures reliable operation in harsh industrial environments, withstanding temperature extremes and electromagnetic interference. By delivering accurate and stable outputs, the AO810V2 enables precise control of critical processes, enhancing efficiency and product quality.

Core advantages and technical highlights

Precise output control

The AO810V2 delivers ±0.1% accuracy and 16-bit resolution, ensuring tight control over analog outputs. In a water treatment plant, it regulates a chemical dosing valve with 4-20 mA signals, maintaining precise chemical concentrations within ±0.5% of setpoint—critical for meeting water quality standards. This level of precision minimizes waste and ensures consistent process performance compared to lower-resolution modules.

Flexible signal configuration

Each channel of the AO810V2 can be independently configured for current or voltage outputs, eliminating the need for separate modules. In a food processing facility, one channel might control a temperature valve via 4-20 mA, while another adjusts a conveyor speed via 0-10 V—all within a single AO810V2. This versatility reduces inventory costs and simplifies system design, especially in mixed-signal applications.

Robust industrial design

With 2.5 kV AC isolation and operation from -25°C to +70°C, the AO810V2 thrives in demanding environments. In a steel mill, where electrical noise from large motors is prevalent, its isolation prevents signal distortion, ensuring accurate control of rolling mill pressure valves. The module’s rugged construction also resists vibration, making it suitable for installation near pumps and compressors.

ABB AO810V2

Typical application scenarios

In a large-scale chemical processing plant, the AO810V2 plays a central role in regulating reactor conditions. Connected to the AC800M controller via the S800 I/O system, its 4 channels control:

- A 4-20 mA flow control valve for raw material feed

- A ±10 V positioner for reactor stirrer speed

- A 0-20 mA pressure regulator for reactor vessel

- A 0-10 V damper actuator for exhaust gas flow

The AO810V2 receives digital setpoints from the controller, converting them into precise analog signals to maintain optimal reaction conditions. During batch processing, it adjusts outputs in real-time based on feedback from AI810 modules monitoring temperature and pressure, ensuring product consistency. Its fast update rate (100 ms) enables rapid response to process changes, preventing deviations that could compromise batch quality.

In a building management system, the AO810V2 controls HVAC equipment across multiple zones. It adjusts chilled water valves (4-20 mA) and fan speed controllers (0-10 V) to maintain temperature setpoints, optimizing energy usage while ensuring occupant comfort.

Related model recommendations

- AI810 3BSE008516R1: An analog input module that works with AO810V2in closed-loop control systems, providing feedback for output adjustments.

- TB820V2: A terminal base that provides secure wiring connections for AO810V2, facilitating easy installation and maintenance.

- AO820: An 8-channel analog output module, ideal for applications requiring more channels than the AO810V2can provide.

- DO810: A digital output module that complements AO810V2by controlling discrete devices (e.g., pumps) alongside analog actuators.

- CI810B 3BSE020520R: A Profibus DP module that enables communication between the controller (connected to AO810V2) and remote I/O systems.

- FENA-11: An Ethernet adapter that allows remote monitoring and configuration of systems incorporating AO810V2

Installation, commissioning and maintenance instructions

Installation preparation

Before installing AO810V2, ensure the control cabinet is clean, dry, and within the -25°C to +70°C operating range. Use a torque screwdriver (0.5-0.8 Nm) to mount the TB820V2 terminal base on a 35 mm DIN rail, then plug the AO810V2 into the base until it clicks. Use shielded twisted-pair cables (0.5-1.5 mm²) for field connections, grounding shields at both ends to reduce noise. Verify 24 V DC power polarity before connecting to avoid damage. Configure channel signal types via the AC800M controller software prior to commissioning.

Maintenance suggestions

Daily checks of AO810V2 involve verifying green LEDs for power and active channels; red LEDs indicate faults (e.g., overcurrent). Calibrate annually using a precision multimeter to ensure ±0.1% accuracy—critical for regulated processes. Inspect terminal connections quarterly for corrosion or looseness, tightening screws to 0.6 Nm if needed. If a channel fails, swap loads between channels to isolate issues: replace AO810V2 with an ABB-approved spare if internal faults are confirmed, ensuring the replacement is configured to match original signal types and ranges.

Service and guarantee commitment

The AO810V2 is backed by a 3-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s technical support team provides 24/7 assistance for installation, configuration, and troubleshooting, including guidance on optimizing output accuracy and integrating with AC800M controllers and AI810 3BSE008516R1 modules.

Customers receive detailed calibration procedures and wiring diagrams to ensure optimal performance. Extended service contracts offer on-site maintenance and firmware updates, keeping AO810V2 compatible with the latest controller software. ABB’s global service network ensures fast delivery of replacement modules, minimizing downtime in critical applications. Trust the AO810V2 to deliver reliable analog output control, backed by ABB’s expertise in industrial automation.