Description

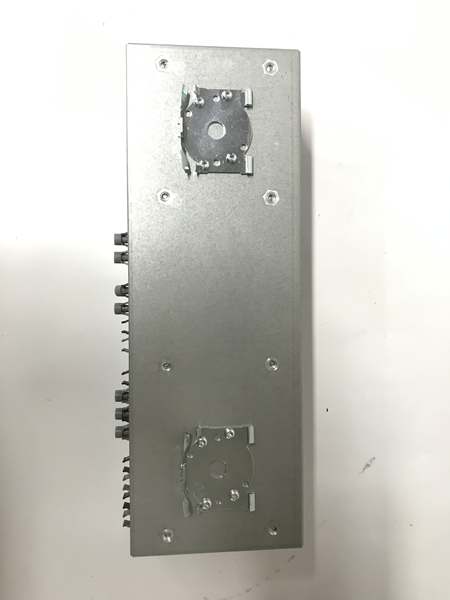

ABB APBU-44C 64669982

- ••

Model Number: APBU-44C - ••

Manufacturer Part Number: 64669982 - ••

Manufacturer: ABB - ••

Product Type: I/O Module Baseplate Assembly - ••

Compatible System: S800 I/O - ••

Module Capacity: Typically 1-8 modules (depends on specific configuration) - ••

Backplane: Integrated backplane for power and communication - ••

Power Distribution: 24V DC to mounted modules - ••

Field Connection: Screw terminal blocks or FTA interface - ••

Mounting: DIN rail or direct panel mounting - ••

Operating Temperature: -25°C to +70°C - ••

Isolation: Channel-to-channel and system-to-field isolation - ••

Certifications: UL, CE, ATEX (for hazardous areas) ABB APBU-44C 64669982