Description

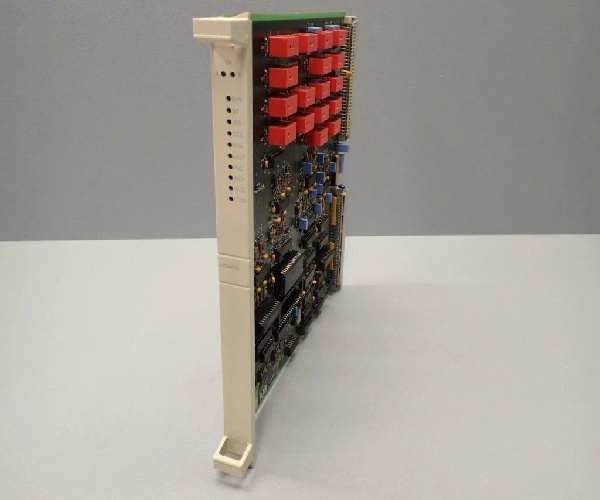

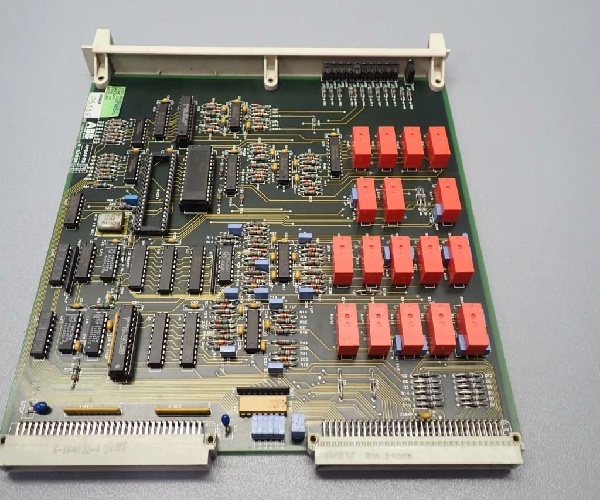

ABB APSAF-03: Product Overview

The ABB APSAF-03 is a safety logic board designed for industrial robotic systems requiring compliance with ISO 13849-1 safety standards. It integrates safety-critical functions such as emergency stop (e-stop) processing, safety gate monitoring, and machine guarding control. Positioned between the robot controller (e.g., ABB IRC5) and peripheral safety devices (e.g., light curtains, safety mats), this module ensures safe shutdown sequences and fault detection in collaborative and non-collaborative robotic applications.

Core Responsibilities:

-

Safety Signal Processing:

-

Monitors 16 input channels for safety devices (e.g., e-stop buttons, interlock switches).

-

Controls 16 output channels to activate safety relays or shutdown actuators.

-

-

Safety Logic Execution:

-

Implements SIL2/PLd-rated safety functions, including watchdog timers and cross-channel monitoring.

-

Supports configurable safety logic via ABB’s RobotStudio software.

-

-

Diagnostic Monitoring:

-

Continuously checks for wire breaks, short circuits, and device faults conditions.

-

Provides real-time status updates to the robot controller via Ethernet/IP.

-

Platform Integration:

Part of ABB’s Robot Safety Ecosystem, the APSAF-03 is compatible with ABB’s SafeMove2 safety software and integrates with S4C+ controllers. Its modular design allows seamless replacement or upgrades in existing systems.

ABB APSAF-03

Technical Specifications

-

Model: APSAF-03

-

Manufacturer: ABB Ltd.

-

Product Type: Safety Logic Board

-

Input Voltage: 24V DC ±10% (24W max)

-

Logic Supply: 5V DC (internal regulator)

-

Channels: 16 inputs / 16 outputs (configurable as digital I/O)

-

Communication Protocols: Ethernet/IP, PROFINET RT, OPC UA

-

Safety Standards: EN ISO 13849-1 (Cat 4), IEC 62061 (SIL2)

-

Response Time: ≤0.5 ms (safety function execution)

-

Environmental:

-

Temperature: -20°C to +50°C

-

Humidity: 0–95% non-condensing

-

-

Certifications: CE, UL, RoHS

Core Features & Customer Value

-

Dual-Channel Safety Architecture:

-

Redundant signal paths ensure fault tolerance. If one channel fails, the backup channel maintains safety functionality, reducing unplanned downtime in automotive or pharmaceutical manufacturing.

-

-

Compact Form Factor:

-

DIN-rail mountable design saves panel space in control cabinets, critical for retrofitting legacy robotic systems.

-

-

Seamless Integration:

-

Pre-certified communication drivers simplify integration with ABB Robot Controllers and third-party PLCs (e.g., Siemens SIMATIC).

-

-

Diagnostic Alerts:

-

Built-in LED indicators and fault codes (e.g., “E-STOP TRIPPED”) accelerate troubleshooting, minimizing mean time to repair (MTTR).

ABB APSAF-03

-

Typical Applications

-

Automotive Manufacturing:

-

Safeguards robotic welding arms and paint lines during emergency stops.

-

Ensures compliance with ISO 10218 for human-robot collaboration.

-

-

Logistics & Warehousing:

-

Controls AGV docking and palletizing systems, preventing motion during maintenance.

-

-

Food Processing:

-

Monitors safety gates on robotic deboning lines to halt operations if contamination is detected.

-

-

Solar Panel Assembly:

-

Protects robotic arms handling fragile solar cells from unintended motion.

-