Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | AV94A HESG440940R11 HESG216791/A |

| Manufacturer | ABB |

| Product category | Industrial control module (compatible with ABB industrial drive systems) |

| Operating voltage | 24 V DC ±10% |

| Input signals | 8 digital inputs (24 V DC, PNP/NPN configurable) |

| Output signals | 4 relay outputs (NO/NC configurable, 250 V AC/30 V DC, 5 A max) |

| Communication interface | Profibus DP, RS485 |

| Processing speed | 100 μs per instruction |

| Operating temperature | -10°C to 60°C |

| Storage temperature | -25°C to 70°C |

| Protection rating | IP20 (module), IP65 (with optional protective housing) |

| Dimensions | 120mm × 80mm × 60mm |

| Weight | 0.6 kg |

| Certifications | IEC 61131-2, CE, UL, RoHS |

| Mounting type | DIN rail (35mm) |

| Power consumption | Max 15 W |

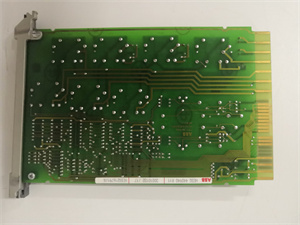

ABB AV94A HESG440940R11 HESG216791/A

Product introduction

The ABB AV94A HESG440940R11 HESG216791/A is a high-performance industrial control module engineered to seamlessly integrate with ABB’s industrial drive systems, serving as a critical interface for precise control and monitoring of motor-driven processes. This module is designed to bridge the gap between field sensors, actuators, and higher-level control systems, making it an essential component in automation setups across industries such as manufacturing, logistics, and energy.

Featuring 8 configurable digital inputs and 4 versatile relay outputs, the ABB AV94A offers exceptional flexibility in connecting to a wide range of industrial devices—from limit switches and photoelectric sensors to contactors and alarm indicators. Its dual communication interfaces (Profibus DP and RS485) enable seamless data exchange with PLCs, SCADA systems, and other automation components, ensuring real-time synchronization of process data.

Built with ruggedness in mind, the ABB AV94A operates reliably in harsh industrial environments, withstanding temperature fluctuations from -10°C to 60°C and resisting electromagnetic interference. Its compact design (120mm × 80mm × 60mm) allows for easy installation in space-constrained control cabinets, while the IP20 protection rating ensures safety in dust-prone settings. Whether deployed in conveyor systems, pumps, or fans, this module delivers consistent performance for optimizing operational efficiency.

Core advantages and technical highlights

Versatile I/O configuration

The ABB AV94A comes equipped with 8 digital inputs (configurable for PNP or NPN logic) and 4 relay outputs (switchable between normally open/closed), providing unmatched adaptability for diverse industrial applications. For example, in a packaging line, the inputs can connect to photoelectric sensors detecting product presence, while the outputs control conveyor stop/start relays and reject mechanisms for defective items. This configurability eliminates the need for multiple specialized modules, reducing inventory and installation complexity.

High-speed data processing

With a processing speed of 100 μs per instruction, the module ensures rapid response to input signals—critical for time-sensitive processes like high-speed sorting systems or precision assembly lines. This speed minimizes latency between sensor detection and actuator response, preventing bottlenecks and improving overall throughput. For instance, in a logistics sorting facility, the module can process barcode scanner inputs and trigger diverter valves in under 1ms, ensuring accurate package routing.

Robust communication capabilities

Dual communication interfaces (Profibus DP and RS485) enable the ABB AV94A to integrate into both legacy and modern automation networks. Profibus DP supports high-speed data transfer (up to 12 Mbps) for real-time control, while RS485 facilitates long-distance communication (up to 1200 meters) with SCADA systems or remote monitoring stations. This dual capability ensures compatibility with existing infrastructure during plant upgrades, reducing retrofitting costs.

Industrial-grade durability

Designed to operate in -10°C to 60°C environments, the ABB AV94A thrives in extreme conditions—from freezing cold storage facilities to hot foundries. Its circuitry is protected against voltage transients and electrostatic discharge (ESD), ensuring reliability near large motors or variable frequency drives. The module’s compliance with IEC 61131-2 standards guarantees performance stability under vibration (10-500 Hz) and shock (15 g peak), making it suitable for mobile equipment like automated guided vehicles (AGVs).

Enhanced safety features

The relay outputs feature built-in overcurrent protection (5 A max), preventing damage to connected devices during short circuits. Additionally, the module’s isolation design (2.5 kV between I/O and communication circuits) eliminates ground loops, safeguarding sensitive control systems from electrical noise. In safety-critical applications—such as elevator control panels—the ABB AV94A can be configured to trigger emergency stops via dedicated relay outputs, meeting EN 13849-1 safety standards.

Typical application scenarios

Manufacturing automation

In an automotive assembly plant, the ABB AV94A controls robotic welding stations. Its digital inputs connect to proximity sensors detecting workpiece positioning, while outputs activate welding guns and clamping cylinders. The Profibus DP interface synchronizes with the plant’s PLC, ensuring weld timing aligns with conveyor movement. The module’s fast processing speed (100 μs) prevents misalignment errors, reducing rework rates and improving production quality.

Logistics and material handling

In a warehouse conveyor system, the ABB AV94A manages product routing. Inputs from barcode scanners identify package destinations, and outputs trigger diverter valves to direct items to the correct shipping lane. The RS485 interface sends real-time throughput data to a central SCADA system, enabling managers to optimize conveyor speeds. During peak operations, the module’s robust design handles continuous 24/7 operation without performance degradation.

Water and wastewater treatment

The ABB AV94A monitors and controls pump stations in wastewater facilities. Its inputs connect to level sensors in storage tanks, while outputs activate pump motors and valve actuators. The module communicates via Profibus DP with a master PLC, which adjusts pump operation based on flow rates. The relay outputs include a dedicated alarm circuit that triggers 声光警报 when tank levels exceed safe limits, ensuring regulatory compliance.

Renewable energy systems

In a solar power plant, the ABB AV94A controls tracker systems that align solar panels with the sun. Inputs from light sensors and inclinometers detect sun position, while outputs adjust motorized actuators for panel angles. The RS485 interface transmits performance data to a central management system, which optimizes tracking algorithms. The module’s wide operating temperature range (-10°C to 60°C) ensures reliable operation in desert climates.

ABB AV94A HESG440940R11 HESG216791/A

Related model recommendations

ABB AV94B HESG440941R11: A higher-density variant with 16 digital inputs and 8 relay outputs, suitable for large-scale automation systems.

ABB ACS880-01: An industrial drive that pairs seamlessly with the ABB AV94A, enabling precise motor speed control and energy optimization.

ABB CI854A 3BSE022469R1: A Profibus DP interface module that extends the ABB AV94A’s communication range in distributed control systems.

ABB TB857 3BSE013269R1: A surge-protected terminal block that enhances the ABB AV94A’s noise immunity in high-EMI environments (e.g., near large motors).

ABB AC500 PLC: A compact controller that integrates with the ABB AV94A for advanced logic programming, ideal for standalone automation cells.

ABB 800xA DCS: A distributed control system that visualizes data from the ABB AV94A, enabling plant-wide process optimization.

Installation, commissioning and maintenance instructions

Installation preparation

Mount the ABB AV94A on a 35mm DIN rail in a control cabinet, ensuring 50mm clearance above/below for ventilation. Avoid locations exposed to direct sunlight or excessive vibration.

Verify the power supply matches 24 V DC ±10% and install a 1A fuse in the supply line to protect against overcurrent.

Use shielded twisted-pair cables (0.5-1.0 mm²) for I/O connections, with shields grounded at both ends. For Profibus DP, use a dedicated communication cable (RS485 standard) with a maximum length of 1200 meters at 9.6 kbps.

Prepare tools: torque screwdriver (0.5-0.8 Nm), wire strippers, and a multimeter for continuity checks.

Commissioning steps

Power on the module and verify the green “POWER” LED illuminates. Check for fault LEDs (red) indicating wiring errors.

Use ABB’s Engineering Software to configure input logic (PNP/NPN) and output modes (NO/NC) via the module’s Profibus DP interface.

Test each input by connecting a 24 V DC signal and confirming the corresponding LED activates. For outputs, energize each relay and verify contact closure with a multimeter.

Validate communication by sending test signals between the ABB AV94A and the host PLC. Ensure data updates in real time (latency <10 ms).

Perform a full system test: simulate sensor inputs (e.g., trigger a limit switch) and confirm the module activates the correct output (e.g., stop a motor).

Maintenance suggestions

Inspect the ABB AV94A quarterly for dust accumulation; clean with compressed air (low pressure) to prevent overheating.

Check wiring connections semi-annually for tightness, especially in vibrating environments. Re-torque terminals to 0.6 Nm if loose.

Test relay outputs annually by measuring contact resistance (should be <100 mΩ). Replace relays if resistance exceeds 1 kΩ to prevent signal loss.

Verify communication integrity monthly using ABB’s diagnostic software. Check for Profibus DP errors (e.g., CRC faults) and replace cables if errors persist.

Store spare modules in a dry environment (-25°C to 70°C) with anti-static packaging to prevent ESD damage.

Service and guarantee commitment

The ABB AV94A HESG440940R11 HESG216791/A comes with a 36-month warranty from installation, covering manufacturing defects and ensuring compliance with performance specifications. ABB guarantees replacement of faulty modules within 48 hours for critical applications, minimizing downtime.

Technical support includes 24/7 access to ABB’s global automation experts, who provide assistance with configuration, troubleshooting, and system integration. Online resources include detailed wiring diagrams, software manuals, and compatibility matrices. Extended service contracts offer annual preventive maintenance, calibration, and on-site support, ensuring the module operates reliably throughout its 10-year design lifespan.