Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | B5EEd HENF105082R4 |

| Manufacturer | ABB |

| Product category | Safety relay module (Safety Integrated system) |

| Safety rating | SIL 3 (IEC 61508), PL e (ISO 13849-1) |

| Input channels | 4 x 24 VDC safety inputs |

| Output channels | 2 x 24 VDC safety outputs (PNP) |

| Response time | <10 ms |

| Operating voltage | 24 VDC ±15% |

| Power consumption | Max 3 W |

| Operating temperature | -25°C to 70°C |

| Protection rating | IP20 (DIN rail housing) |

| Dimensions | 90mm × 35mm × 120mm |

| Weight | 0.28kg |

| Certifications | TÜV, UL, CSA, CE, IECEx |

| Mounting type | DIN rail (35mm) |

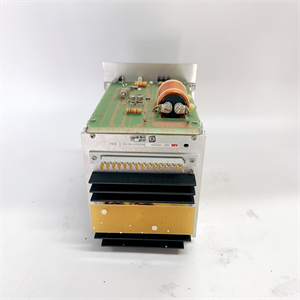

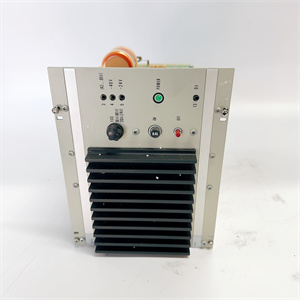

ABB B5EEd HENF105082R4

Product introduction

The ABB B5EEd HENF105082R4 is a high-integrity safety relay module designed for critical safety applications in industrial automation. As a key component of ABB’s Safety Integrated system, it provides reliable monitoring and control of safety-related functions, ensuring the protection of personnel and equipment in hazardous environments.

This compact module combines 4 safety inputs and 2 safety outputs, specifically engineered to handle emergency stop circuits, guard monitoring, and two-hand control applications. The ABB B5EEd HENF105082R4 meets the highest safety standards, including SIL 3 and PL e, making it suitable for use in applications where failure could result in serious injury or significant equipment damage.

Within safety-critical systems, the ABB B5EEd HENF105082R4 acts as a dedicated safety layer, independent of standard control systems. It continuously monitors input signals for faults or hazardous conditions, triggering safety outputs to shut down processes or activate protective measures within milliseconds. This separation of safety and standard control ensures that safety functions remain operational even if the main control system fails.

Core advantages and technical highlights

Advanced safety integrity: Certified to SIL 3 (IEC 61508) and PL e (ISO 13849-1), the ABB B5EEd HENF105082R4 delivers the highest level of safety performance for industrial applications. Its architecture includes dual-channel processing with self-monitoring capabilities, ensuring that internal faults are detected and addressed before they compromise safety functions. This makes it ideal for protecting operators around high-risk machinery such as presses, robotic cells, and material handling systems.

Rapid response capability: With a response time of less than 10 ms, the ABB B5EEd HENF105082R4 ensures that safety actions are initiated almost instantly when a hazardous condition is detected. Whether responding to an emergency stop button activation or a guard door opening, this rapid response minimizes exposure to danger, reducing the risk of injury in fast-moving industrial environments.

Flexible configuration: The ABB B5EEd HENF105082R4 offers versatile wiring options for its 4 safety inputs, supporting both normally open and normally closed configurations. This flexibility allows it to integrate with various safety devices, including emergency stop buttons, light curtains, and interlock switches, without requiring additional interface modules. The module’s pluggable terminals simplify installation and reduce wiring errors, saving time during system setup.

Wide operational range: Designed to thrive in harsh industrial conditions, the ABB B5EEd HENF105082R4 operates reliably across a temperature range of -25°C to 70°C. This durability ensures consistent performance in environments such as cold storage facilities, foundries, and outdoor installations, where temperature extremes might affect less robust safety components. Its resistance to electrical noise further enhances reliability in high-EMI environments.

Typical application scenarios

In automotive stamping plants, the ABB B5EEd HENF105082R4 monitors safety light curtains and emergency stop buttons surrounding robotic press cells. When a worker enters the protected area, the module immediately triggers the safety outputs to stop the press and lock the robot, preventing crush injuries. Its SIL 3 rating ensures this protection meets the strict safety requirements of heavy machinery operation.

Within packaging machinery, the ABB B5EEd HENF105082R4 controls access to rotating parts by monitoring guard door interlocks. If a door is opened during operation, the module shuts down the drive system within 10 ms, preventing entanglement hazards. Its compact size allows installation in space-constrained machine enclosures, while its wide temperature tolerance handles the heat generated by continuous operation.

In food processing facilities, the ABB B5EEd HENF105082R4 manages two-hand control stations for filling machines, ensuring operators keep both hands clear of moving parts during the filling cycle. The module’s resistance to electrical noise ensures reliable operation near washdown equipment, and its certification to food industry standards (via IECEx) confirms compatibility with hygienic environments.

ABB B5EEd HENF105082R4

Related model recommendations

ABB B5EEd HENF105083R4: A variant with 6 safety inputs, offering expanded monitoring capabilities for larger safety systems than the ABB B5EEd HENF105082R4.

ABB MS132: A manual motor starter that works with the ABB B5EEd HENF105082R4 to safely disconnect motor power in emergency situations.

ABB S200 miniature circuit breaker: Provides overcurrent protection for the ABB B5EEd HENF105082R4 and associated safety devices.

ABB TB483 terminal block: Simplifies wiring connections for the ABB B5EEd HENF105082R4, ensuring secure and organized terminations.

ABB 2TLA020074R0000: An emergency stop button directly compatible with the inputs of the ABB B5EEd HENF105082R4.

ABB C2000 contactor: Controlled by the ABB B5EEd HENF105082R4 to safely disconnect power to machinery during safety events.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB B5EEd HENF105082R4, ensure the 35mm DIN rail is securely mounted and properly grounded to prevent electrical interference. Verify the ambient temperature is within -25°C to 70°C and humidity is below 95% RH (non-condensing). Required tools include a torque screwdriver (0.5-0.8 Nm), wire strippers, and a multimeter. Use 0.5-1.5 mm² cables for all connections, and ensure the 24 VDC power supply is properly fused (1A recommended) and isolated from non-safety circuits.

Maintenance suggestions: Inspect the ABB B5EEd HENF105082R4 quarterly for loose connections or dust accumulation; clean with a dry cloth if necessary. Perform monthly functional tests by activating each safety input (e.g., pressing emergency stop buttons) and verifying the corresponding safety output deactivation. Check the module’s status LED—steady green indicates normal operation, while red or flashing LEDs signal faults requiring immediate attention. Replace the module if fault codes persist after checking wiring. Always use ABB-approved spare parts to maintain safety certifications.

Service and guarantee commitment

The ABB B5EEd HENF105082R4 comes with a 36-month warranty from the date of installation, covering manufacturing defects and ensuring compliance with published safety specifications. ABB guarantees that any module failing to meet safety standards during this period will be replaced within 48 hours to minimize safety system downtime.

Technical support includes access to ABB’s safety engineering specialists, available for assistance with configuration, wiring, and compliance documentation. Online resources include safety manual excerpts, wiring diagrams, and certification documents specific to the ABB B5EEd HENF105082R4. Customers can opt for extended safety audits as part of service contracts, ensuring the module maintains its safety integrity throughout its 10-year design lifespan.