Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | B5EEd HENF105082R4 |

| Manufacturer | ABB |

| Product category | Industrial fieldbus interface module |

| Supported protocols | FOUNDATION Fieldbus H1, PROFIBUS PA |

| Communication rate | 31.25 kbps (Fieldbus H1), 31.25 kbps (PROFIBUS PA) |

| Number of ports | 2 x Fieldbus H1 (M12), 1 x PROFIBUS PA (sub-D 9) |

| Power supply | 24 V DC ±15% (backplane) + 12-32 V DC (bus power) |

| Power consumption | Max 5 W (backplane) + 1.2 W (bus power) |

| Isolation | 2.5 kV AC (field to backplane) |

| Operating temperature | -40°C to 70°C |

| Protection rating | IP20 (module) / IP67 (with field connectors) |

| Mounting type | Backplane mount (compatible with AC800M/S800 series) |

| Dimensions | 110mm × 160mm × 80mm |

| Certifications | CE, UL, ATEX, IEC 61158, IEC 61784-1 |

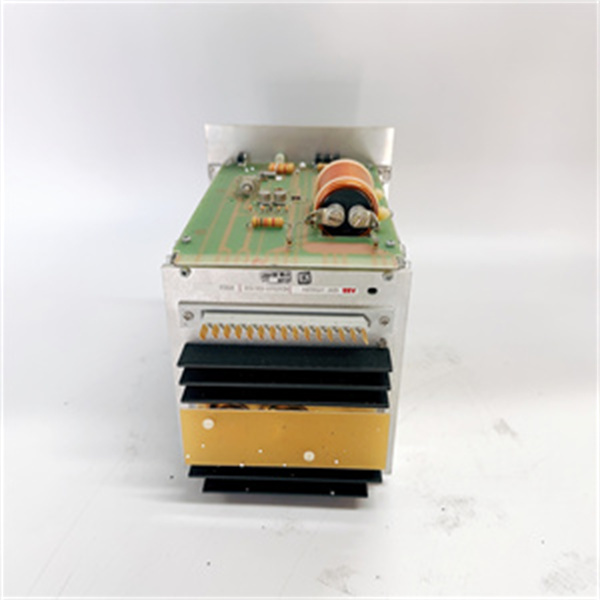

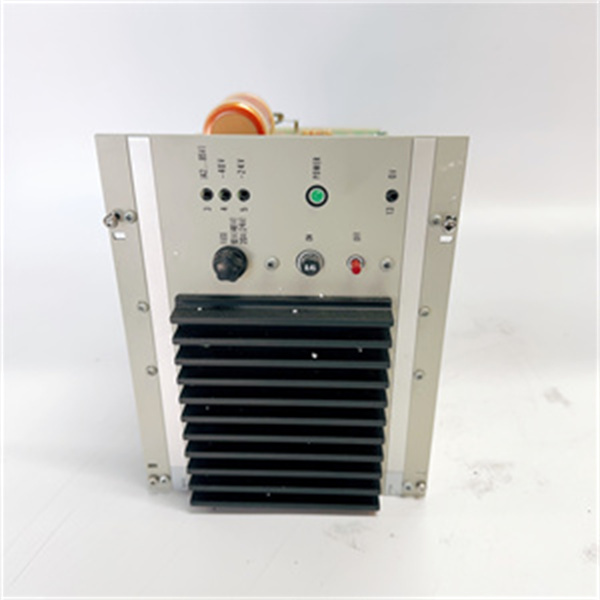

ABB B5EEd HENF105082R4

Product introduction

The B5EEd HENF105082R4 is a dual-protocol fieldbus interface module from ABB, designed to bridge industrial control systems with FOUNDATION Fieldbus H1 and PROFIBUS PA devices. As a critical component in ABB’s process automation portfolio, this module serves as a communication gateway between central controllers like the 3BHE024577R0101 PPC907BE AMC34 processor and field instruments (such as pressure transmitters, flow meters, and analytical sensors), enabling seamless data exchange in process plants.

Unlike single-protocol fieldbus modules, the B5EEd HENF105082R4 supports both FOUNDATION Fieldbus H1 and PROFIBUS PA standards, making it ideal for mixed-network environments common in chemical, oil & gas, and pharmaceutical facilities. Whether integrating legacy PROFIBUS PA devices or modern Fieldbus H1 instruments, this module ensures reliable communication with high data integrity, supporting advanced features like device configuration, diagnostics, and parameter tuning directly from the control system.

Core advantages and technical highlights

Dual-protocol flexibility: The B5EEd HENF105082R4 natively supports both FOUNDATION Fieldbus H1 and PROFIBUS PA, eliminating the need for separate interface modules in plants with mixed fieldbus infrastructures. In a refinery, this allows the module to connect 16 Fieldbus H1 temperature transmitters in the distillation unit and 8 PROFIBUS PA pressure sensors in the pumping station to a single PPC907BE AMC34 controller, reducing backplane space by 40% and simplifying system architecture.

Integrated bus power management: Equipped with built-in bus power conditioning, the module supplies 9-32 V DC to field devices via the communication bus, eliminating the need for external power supplies. This feature is particularly valuable in hazardous areas (ATEX-certified), where it reduces the number of explosion-proof enclosures required for power distribution. In a chemical plant’s reactor zone, it powers 12 Fieldbus H1 analyzers through a single bus, minimizing cable runs and installation costs.

Advanced diagnostic capabilities: The module provides real-time diagnostics for both communication networks, including signal strength, device status, and fault location. In a water treatment plant, this allows operators to quickly identify a faulty PROFIBUS PA valve positioner or a degraded Fieldbus H1 segment via the HMI80 panel, reducing troubleshooting time by up to 60%. Diagnostic data is transmitted to the controller via OPC UA, enabling predictive maintenance scheduling.

Robust hazardous area certification: With ATEX and IECEx certifications for Zone 2/Class I Div 2 environments, the B5EEd HENF105082R4 is suitable for deployment in explosive atmospheres. Its 2.5 kV AC isolation between field and backplane circuits prevents ground loops and ensures safe operation even in noisy industrial environments, such as offshore platforms with high electromagnetic interference from motors and generators.

Seamless system integration: Designed for compatibility with ABB’s AC800M/S800 backplanes, the module integrates with power distribution modules like the PPD513A25-111615 and communication gateways such as the GCC960C103. It supports hot swapping, allowing replacement without shutting down the control system—a critical feature in continuous processes like ethylene production. The module’s configuration is managed via ABB’s Control Builder M software, enabling centralized setup of both Fieldbus H1 and PROFIBUS PA networks.

Typical application scenarios

In a pharmaceutical batch processing plant, the B5EEd HENF105082R4 connects 10 FOUNDATION Fieldbus H1 devices (including pH sensors, conductivity meters, and temperature transmitters) in the mixing vessel area and 6 PROFIBUS PA valves in the ingredient dosing system. It enables the PPC907BE AMC34 controller to adjust pH levels in real time by modifying setpoints on the Fieldbus H1 analyzers while monitoring valve positions via PROFIBUS PA. The module’s diagnostic alerts notify operators of a drifting temperature sensor before it impacts batch quality, ensuring compliance with FDA regulations.

In an offshore oil platform, the module operates in a Zone 2 environment, linking 14 PROFIBUS PA pressure transmitters on the wellhead and 8 Fieldbus H1 flow meters in the separation process to the central DCS. Its robust design withstands extreme temperatures (-40°C to 70°C) and vibration, ensuring reliable communication during harsh weather conditions. Integrated bus power management reduces the number of explosion-proof junction boxes, lowering installation and maintenance costs in this space-constrained environment.

ABB B5EEd HENF105082R4

Related model recommendations

B5EEd HENF105083R5: A redundant variant of the B5EEd HENF105082R4 with dual backplane connections, ideal for safety-critical applications requiring 24/7 availability.

AI880-1: ABB’s analog input module that complements the fieldbus module for monitoring non-bus sensors.

3BHE024577R0101 PPC907BE AMC34: ABB’s processor module that processes data from the B5EEd HENF105082R4.

GCC960C103: ABB’s communication gateway that routes fieldbus data to enterprise systems via OPC UA.

PPD513A25-111615 3BHE039724R2565: ABB’s power distribution module that supplies stable backplane power to the fieldbus interface.

TB857: ABB’s surge protection device that safeguards the module from voltage transients in field wiring.

HMI80: ABB’s touchscreen panel that visualizes fieldbus network status and device diagnostics from the B5EEd HENF105082R4.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the B5EEd HENF105082R4 into a compatible S800 backplane using the front-panel screw, torquing to 0.5 Nm. Ensure at least 50mm clearance for ventilation. Connect field devices using shielded twisted-pair cable (0.8mm²) with M12 connectors for Fieldbus H1 and sub-D 9 for PROFIBUS PA. Ground all shields at the module end and terminate bus power according to ATEX guidelines in hazardous areas. Required tools include a torque screwdriver, wire strippers, and a fieldbus signal tester. Power off the backplane during installation.

Commissioning steps: Use ABB’s Control Builder M software to configure network parameters (baud rate, device addresses) and map fieldbus variables to the controller’s address space. Perform a bus scan to detect connected devices and verify communication integrity using a fieldbus analyzer. Test redundancy (if applicable) by disconnecting one bus segment and confirming failover to the backup path. Calibrate device parameters (e.g., sensor ranges) via the module’s interface, saving configurations to non-volatile memory.

Maintenance suggestions: Inspect the module quarterly for loose connections, dust accumulation, and LED status (power: green, communication: flashing green, fault: red). Clean ventilation slots with compressed air. Monitor bus health monthly using the built-in diagnostic tools, checking for signal degradation (>3 dB loss indicates cable issues). Test isolation resistance annually with a megohmmeter (minimum 100 MΩ at 500 V DC). In hazardous areas, perform visual inspections of cable glands and enclosures to ensure ATEX compliance. Replace the module with an ABB-certified unit if communication faults persist after verifying field wiring.

Service and guarantee commitment

The B5EEd HENF105082R4 comes with a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with fieldbus protocol standards. ABB guarantees technical support response within 4 hours for critical applications, with on-site troubleshooting available in 72 hours for qualified industrial facilities. The module includes 3 years of free firmware updates and access to ABB’s fieldbus compatibility database. Extended service contracts offer annual network audits, protocol validation, and priority support, ensuring reliable operation throughout its 15-year design lifespan. Customers receive dedicated online resources, including wiring diagrams, network design guides, and hazardous area installation instructions specific to this model.