Description

Detailed parameter table

| Parameter name | Parameter value |

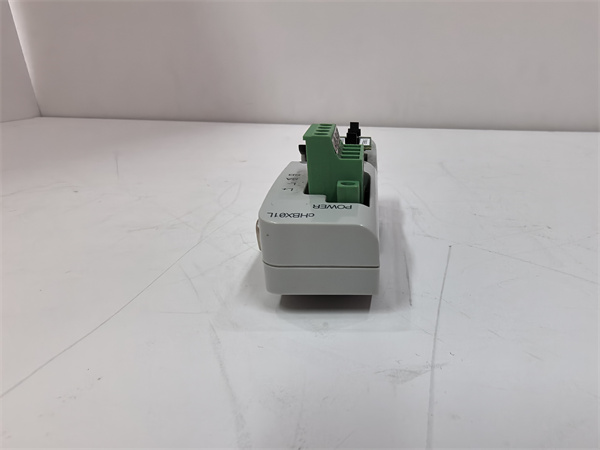

| Product model | CHBX01L 2VAA008574R1 |

| Manufacturer | ABB |

| Product category | Control hardware backplane module (for distributed control systems) |

| Number of slots | 8 expansion slots |

| Data transfer rate | Up to 1 Gbps (backplane bus) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | Max 5 W |

| Operating temperature | -10°C to 60°C |

| Protection rating | IP20 |

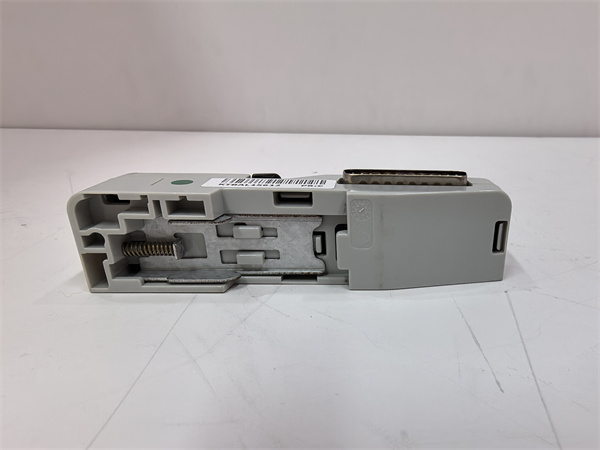

| Mounting type | DIN rail (35mm) or panel mounting |

| Dimensions | 220mm × 160mm × 50mm |

| Weight | 0.8 kg |

| Certifications | IEC 61131-2, CE, UL, RoHS |

| Compatibility | ABB AC 800M and AC 500 PLC systems |

| Redundancy support | Optional dual power supply |

ABB CHBX01L 2VAA008574R1

Product introduction

The CHBX01L 2VAA008574R1 is a high-performance backplane module from ABB, designed to serve as the central connectivity hub for distributed control systems. As a critical infrastructure component in ABB’s automation portfolio, this module provides a robust platform for integrating various I/O modules, communication interfaces, and processing units, enabling seamless data exchange within control systems.

What defines the CHBX01L 2VAA008574R1 is its 8-slot design, which offers flexible expansion capabilities for customizing control systems to specific application needs. Whether populated with analog I/O modules, digital signal processors, or communication gateways, the CHBX01L 2VAA008574R1 ensures high-speed data transmission via its 1 Gbps backplane bus, minimizing latency in time-critical processes. Compatible with ABB’s AC 800M DCS and AC 500 PLC systems, it serves as a versatile building block for automation solutions in industries ranging from manufacturing to energy production, where system scalability and reliability are paramount.

Core advantages and technical highlights

High-speed data backbone: The CHBX01L 2VAA008574R1 features a 1 Gbps backplane bus that enables rapid communication between connected modules, ensuring real-time data transfer in complex control loops. This speed is crucial for applications like synchronized motor control in automotive assembly lines, where delays of even milliseconds can disrupt production sequences. The bus architecture supports parallel data processing, allowing multiple modules to exchange information simultaneously without bottlenecks.

Flexible system expansion: With 8 slots, the CHBX01L 2VAA008574R1 accommodates a mix of I/O, communication, and processing modules, enabling system designers to tailor configurations to specific requirements. For example, in a water treatment plant, it can integrate 4-20 mA analog modules for sensor inputs, PROFINET communication modules for network connectivity, and safety modules for emergency shutdown logic—all within a single backplane. This flexibility reduces the need for multiple enclosures, simplifying cabinet design and lowering installation costs.

Reliable operation with redundancy options: The CHBX01L 2VAA008574R1 supports optional dual power supplies, ensuring uninterrupted operation even if one supply fails. This redundancy is critical for mission-critical applications such as nuclear power plant control systems, where power interruptions could have severe consequences. The module’s rugged design, including wide operating temperature range (-10°C to 60°C) and resistance to vibration, further enhances reliability in harsh industrial environments.

Seamless system integration: Designed to work with ABB’s AC 800M and AC 500 platforms, the CHBX01L 2VAA008574R1 ensures plug-and-play compatibility with ABB’s ecosystem of modules and software tools. It integrates with ABB’s Control Builder M software, allowing engineers to configure the backplane and connected modules, monitor bus traffic, and troubleshoot issues from a centralized interface. This integration streamlines system commissioning and reduces the risk of compatibility errors.

Typical application scenarios

In industrial manufacturing facilities, the CHBX01L 2VAA008574R1 serves as the backbone of a flexible production line control system. It connects digital input modules monitoring conveyor sensors, analog output modules controlling robotic arm actuators, and Ethernet/IP communication modules linking to a central MES. The high-speed backplane ensures that sensor data from one end of the line is processed and acted upon by robots at the other end within milliseconds, maintaining precise production timing. Its 8-slot design allows for future expansion, such as adding vision system modules as production requirements evolve.

In renewable energy plants, such as solar farms, the CHBX01L 2VAA008574R1 integrates with weather monitoring sensors, inverter control modules, and grid synchronization equipment. The backplane’s fast data transfer enables real-time adjustment of solar panel angles based on light intensity readings, maximizing energy capture. With optional dual power supplies, it ensures continuous operation even during power fluctuations, a critical feature for maintaining grid-compliant energy feed-in.

ABB CHBX01L 2VAA008574R1

Related model recommendations

CHBX02L 2VAA008575R1: A 16-slot variant of the CHBX01L 2VAA008574R1 for larger-scale control systems requiring more module connections.

S-053M 3BHB012897R0003: An analog signal processing module that integrates with the CHBX01L 2VAA008574R1 for sensor data conditioning.

CI854A 3BSE022469R1: A PROFINET communication module that plugs into the CHBX01L 2VAA008574R1 to enable Ethernet connectivity.

AC 800M 3BSE013236R1: A controller module that pairs with the CHBX01L 2VAA008574R1 to manage data flow across connected modules.

PS860 3BSE008549R1: A redundant power supply module compatible with the CHBX01L 2VAA008574R1 for enhanced system reliability.

TB857 3BSE013269R1: A terminal block module that mounts to the CHBX01L 2VAA008574R1 for organized field wiring connections.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the CHBX01L 2VAA008574R1, ensure the mounting surface (DIN rail or panel) can support 1.5 kg (including populated modules). Verify the 24 V DC power supply meets the ±10% tolerance and can deliver at least 1 A to accommodate connected modules. Use a torque screwdriver (1.0-1.2 Nm) for mounting, and ensure the cabinet ambient temperature stays within -10°C to 60°C. Prepare anti-static handling equipment to prevent damage to the backplane’s sensitive electronics during installation.

Maintenance suggestions: Inspect the CHBX01L 2VAA008574R1 quarterly for loose slot connectors or dust accumulation, cleaning with compressed air if necessary. Check power supply voltages monthly to ensure they remain within the 24 V DC ±10% range. Monitor backplane bus traffic using ABB’s diagnostic software to detect anomalies like data collisions or module communication errors. If a slot fails to recognize a module, reseat the module first; if issues persist, test with a known-good module to isolate the fault. Replace the backplane if multiple slots fail or bus errors become persistent.

Service and guarantee commitment

The CHBX01L 2VAA008574R1 comes with a 5-year warranty from the installation date, covering manufacturing defects and ensuring compatibility with ABB’s AC 800M and AC 500 systems. ABB guarantees replacement of faulty units within 48 hours for critical applications, minimizing downtime in control system infrastructure. Technical support is available 24/7 via ABB’s global network of automation specialists, offering assistance with system configuration, backplane troubleshooting, and module compatibility. Extended service contracts include annual preventive maintenance, firmware updates, and priority support, ensuring the CHBX01L 2VAA008574R1 delivers reliable performance throughout its 15-year design lifespan. Customers also gain access to online resources, including installation guides and compatibility matrices specific to this model.