Description

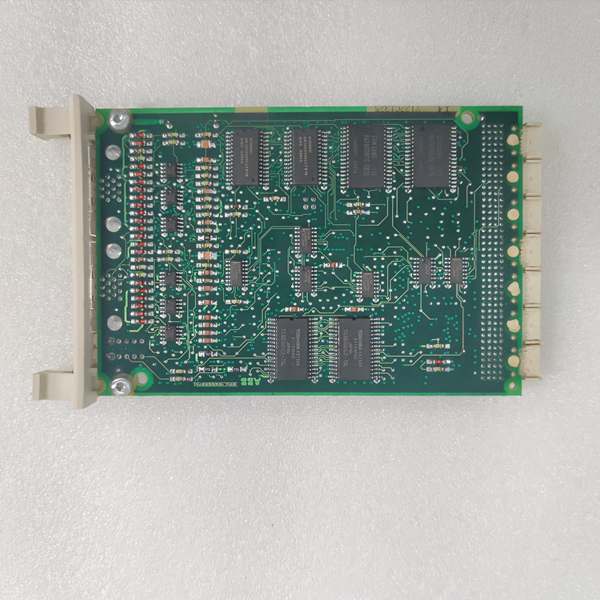

ABB CI522 1SAP222200R0001

-

Model Number: CI522 1SAP222200R0001 -

Manufacturer: ABB -

Product Type: PROFINET IO Communication Module -

Protocol Support: PROFINET IO (Conformance Class A/B, IEC 61158-6-10) -

Ethernet Speed: 10/100Mbps (auto-negotiating) -

Number of Devices: Up to 256 per PROFINET network segment -

Data Capacity: 1440 bytes input + 1440 bytes output per device -

Power Supply: 24V DC (±10% tolerance, drawn from AC500 controller backplane) -

Operating Temperature: -25°C to +55°C -

Storage Temperature: -40°C to +70°C -

Electrical Isolation: 500Vrms (channel-to-bus, channel-to-ground) -

Connector Type: RJ45 (2x for redundant network links, optional) -

Dimensions: 30mm x 100mm x 120mm (WxHxD, fits AC500 controller slot) -

Weight: 0.18kg

ABB CI522 1SAP222200R0001