Description

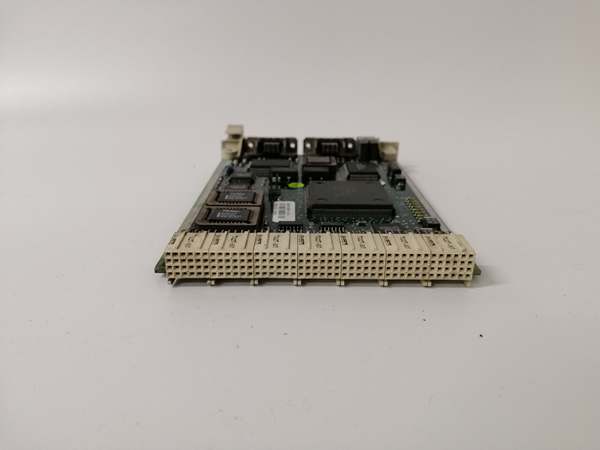

ABB CI522A 3BSE018283R1

-

Model Number: CI522A -

Product Code: 3BSE018283R1 -

Manufacturer: ABB -

Product Type: Communication Interface Module -

Processor: PowerPC 405, 266 MHz -

Memory: 256MB RAM, 512MB Flash (firmware/user configuration) -

Communication Protocol: Profibus DP (up to 12 Mbps, master/slave mode) -

I/O Capacity: Up to 32 distributed I/O modules per segment -

Data Throughput: Up to 8,000 I/O points per second (cyclic exchange) -

Operating Temperature: -25°C to +60°C -

Humidity Range: 5% to 95% non-condensing -

Power Supply: 24V DC (from AC500 rack backplane, 18-32V DC range) -

Power Consumption: 5W (typical) -

Dimensions: 25mm x 128mm x 115mm (width x height x depth, fits AC500 I/O rack) -

Weight: 0.2kg -

Certifications: CE, UL, cULus, RoHS

ABB CI522A 3BSE018283R1