Description

Detailed parameter table

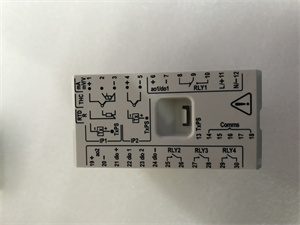

| Parameter name | Parameter value |

| Product model | CM10 |

| Manufacturer | ABB |

| Product category | Compact Motion Controller |

| Control axes | Supports up to 4 axes simultaneously |

| Communication interfaces | Ethernet for high – speed data transfer and network connectivity; CANopen for connection to other industrial devices; Serial port (RS – 232/RS – 485) for legacy systems |

| Input/Output | Multiple digital inputs and outputs for interfacing with sensors, actuators, and other control components. Number of I/O points may vary depending on the specific model, typically around 16 digital inputs and 8 digital outputs |

| Positioning accuracy | ±0.001 mm (for linear axes) and ±0.001° (for rotary axes), enabling high – precision motion control |

| Maximum velocity | Up to 10 m/s for linear axes and 3000 RPM for rotary axes, depending on the connected motors and mechanical systems |

| Motor compatibility | Compatible with a wide range of motors, including servo motors, stepper motors, and brushless DC motors. Can control motors with different power ratings, typically from 0.1 kW to 3 kW |

| Programming environment | Utilizes ABB’s dedicated motion – control programming software, which offers a user – friendly graphical interface for easy programming and configuration. Supports standard programming languages such as IEC 61131 – 3, making it accessible to a wide range of engineers |

| Operating temperature range | 0 °C to 50 °C, suitable for operation in typical industrial environments. May require additional cooling or heating in extreme temperature conditions |

| Storage temperature range | – 20 °C to 70 °C |

| Dimensions (LxWxH) | Approximately 200 mm x 150 mm x 100 mm, providing a compact form – factor for easy integration into control cabinets and machinery |

| Weight | Around 1.5 kg |

| Mounting type | DIN – rail mountable for convenient installation in industrial control panels |

| Protection class | IP20 as standard, protecting against solid objects larger than 12 mm. Can be installed in enclosures with higher protection classes for more demanding environments |

ABB CM10

Product introduction

The ABB CM10 is a high – performance, compact motion controller that lies at the heart of industrial automation systems. As a key component in ABB’s motion – control portfolio, it is designed to precisely control the movement of axes in various machinery and equipment, enabling seamless automation in manufacturing processes.

The CM10 is engineered to interface with a diverse range of motors, sensors, and actuators. It can drive servo motors with extreme accuracy, ensuring smooth and precise motion in applications where positioning accuracy is critical, such as in precision machining centers. For less demanding applications, it can also control stepper motors, providing cost – effective motion control solutions. By receiving input signals from sensors like limit switches and encoders, the CM10 can adjust the motion of the axes in real – time, ensuring the safety and efficiency of the automated process.

Core advantages and technical highlights

High – precision multi – axis control: The CM10’s ability to control up to 4 axes simultaneously with exceptional accuracy sets it apart. In a pick – and – place robot, it can coordinate the movement of multiple joints to precisely pick up and place components with a positioning accuracy of ±0.001 mm. This high – precision control is achieved through advanced motion – control algorithms that optimize acceleration, deceleration, and velocity profiles, resulting in smooth and accurate motion.

Flexible communication capabilities: With Ethernet, CANopen, and serial communication interfaces, the CM10 can easily integrate into existing industrial networks. Ethernet enables high – speed data transfer, allowing for real – time monitoring and control of the motion controller from a central control system. CANopen is useful for connecting to other CAN – based devices in the factory floor, such as variable frequency drives and remote I/O modules. The serial port (RS – 232/RS – 485) provides compatibility with legacy systems, making it easier to upgrade older machinery with the CM10.

User – friendly programming environment: ABB’s dedicated programming software for the CM10, which adheres to the IEC 61131 – 3 standard, makes programming and configuration accessible to a wide range of engineers. The graphical interface allows for easy creation of motion sequences, including point – to – point moves, linear interpolations, and circular interpolations. Engineers can also use ladder logic, function block diagrams, or structured text to program more complex control logic, enabling seamless integration of motion control with other aspects of the automation system.

Wide motor compatibility: The CM10’s compatibility with different types of motors, from small – power servo motors to larger – power brushless DC motors, provides flexibility in system design. In a packaging machine, for example, it can control the servo motor that drives the filling mechanism with high precision, while also controlling the stepper motor that indexes the packaging materials. This versatility eliminates the need for multiple specialized motion controllers, reducing system complexity and cost.

Typical application scenarios

Precision machining: In a CNC milling machine, the CM10 controls the movement of the X, Y, and Z axes, ensuring that the cutting tool moves with high precision to create complex shapes. The controller’s ability to achieve ±0.001 mm positioning accuracy allows for the production of parts with tight tolerances, such as those used in the aerospace and medical device industries. The high – speed communication via Ethernet enables real – time transfer of machining instructions from the CAD/CAM system to the CM10, reducing production time.

Automated assembly lines: In an electronics assembly line, the CM10 is used to control the movement of pick – and – place robots. These robots pick up electronic components from feeders and place them onto printed circuit boards with high accuracy. The CM10 coordinates the movement of multiple axes of the robot, including the arm’s linear and rotational movements, to ensure fast and accurate component placement. The use of CANopen communication allows for seamless integration with other devices on the assembly line, such as component feeders and inspection stations.

Packaging machinery: In a bottling plant, the CM10 controls the movement of the filling heads, capping machines, and labelers. It ensures that the filling heads move precisely to fill bottles with the correct amount of liquid, while the capping machines and labelers operate in sync. The CM10 can also control the conveyor belts, adjusting their speed based on the production rate. The wide motor compatibility of the CM10 allows it to drive different types of motors used in packaging machinery, from servo motors for precise motion control to AC motors for conveyor belt operation.

ABB CM10

Related model recommendations

ACS880 – 01: ABB’s variable speed drive, which can be used in conjunction with the CM10 to control the speed of motors in applications where variable speed is required. In a packaging machine, the CM10 can control the position of the filling heads, while the ACS880 – 01 adjusts the speed of the conveyor belts, ensuring smooth operation of the entire packaging process.

AC500 – EC: ABB’s PLC system, which can be integrated with the CM10 to create a comprehensive control solution. The PLC can handle general – purpose control tasks, such as monitoring sensors and controlling actuators, while the CM10 focuses on motion control. In an automated manufacturing cell, the AC500 – EC can communicate with the CM10 via Ethernet to coordinate the movement of robots and other machinery.

DI01: ABB’s digital input module, which can be connected to the CM10 to provide input signals from sensors. In a precision machining center, the DI01 can receive signals from limit switches and proximity sensors, and send them to the CM10. The CM10 then uses these signals to adjust the motion of the axes, ensuring safe and accurate operation.

DO01: ABB’s digital output module, which can be used with the CM10 to control actuators. In an automated assembly line, the CM10 can send control signals to the DO01, which in turn activates solenoid valves to control the movement of pneumatic actuators that perform tasks such as component gripping and placement.

CI854A: ABB’s Profibus DP communication module, which can be added to the CM10 to enhance its network connectivity. If there is a need to integrate the CM10 into a Profibus – based industrial network, the CI854A enables seamless communication with other Profibus – connected devices, such as PLCs and HMIs.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the CM10, ensure that the DIN – rail is clean, properly grounded, and securely mounted in the control cabinet. Use ESD – safe tools and wear anti – static wristbands to prevent damage to the sensitive electronics during installation. Check the power supply to ensure that it meets the CM10’s voltage and frequency requirements. Connect the communication cables (Ethernet, CANopen, or serial) and I/O cables according to the wiring diagram provided in the user manual. Make sure to route the cables away from power cables to minimize electromagnetic interference.

Commissioning process: After installation, power up the CM10 and check for any error messages on the display or in the programming software. Use ABB’s programming software to configure the controller’s parameters, such as axis settings, motor types, and communication settings. Calibrate the axes by moving them to known positions and verifying the accuracy using sensors or mechanical references. Conduct a series of test runs, starting with simple motion sequences and gradually increasing the complexity. Monitor the performance of the axes, including position accuracy, velocity, and acceleration, and make any necessary adjustments to the parameters.

Maintenance suggestions: Regularly inspect the CM10 for any signs of physical damage, such as loose connections, cracks in the enclosure, or signs of overheating. Clean the controller periodically with a soft, dry cloth to remove dust and debris, which can affect heat dissipation. Check the communication connections for any signs of wear or damage. If communication errors occur, verify the communication settings on the CM10 and the connected devices. Periodically review the motion – control parameters to ensure that they are still optimized for the application. If the application requirements change, adjust the parameters accordingly. Replace any worn – out components, such as connectors or fans, with genuine ABB spare parts to ensure the continued reliable operation of the CM10.

Service and guarantee commitment

ABB provides a 2 – year warranty for the CM10, covering defects in materials and workmanship. During this period, if the controller fails due to manufacturing – related issues, ABB will provide a free replacement or repair. Customers can access ABB’s global technical support network, which is available 24/7 for troubleshooting and technical advice. ABB also offers a comprehensive library of technical documentation, including user manuals, programming guides, and application notes, to assist customers in using and maintaining the CM10. In addition, optional on – site commissioning and maintenance services are available for customers who require hands – on support. ABB ensures the availability of spare parts for a reasonable period after the product’s production phase, minimizing the risk of system downtime due to unavailability of replacement parts.