Description

Detailed parameter table

| Parameter name | Parameter value |

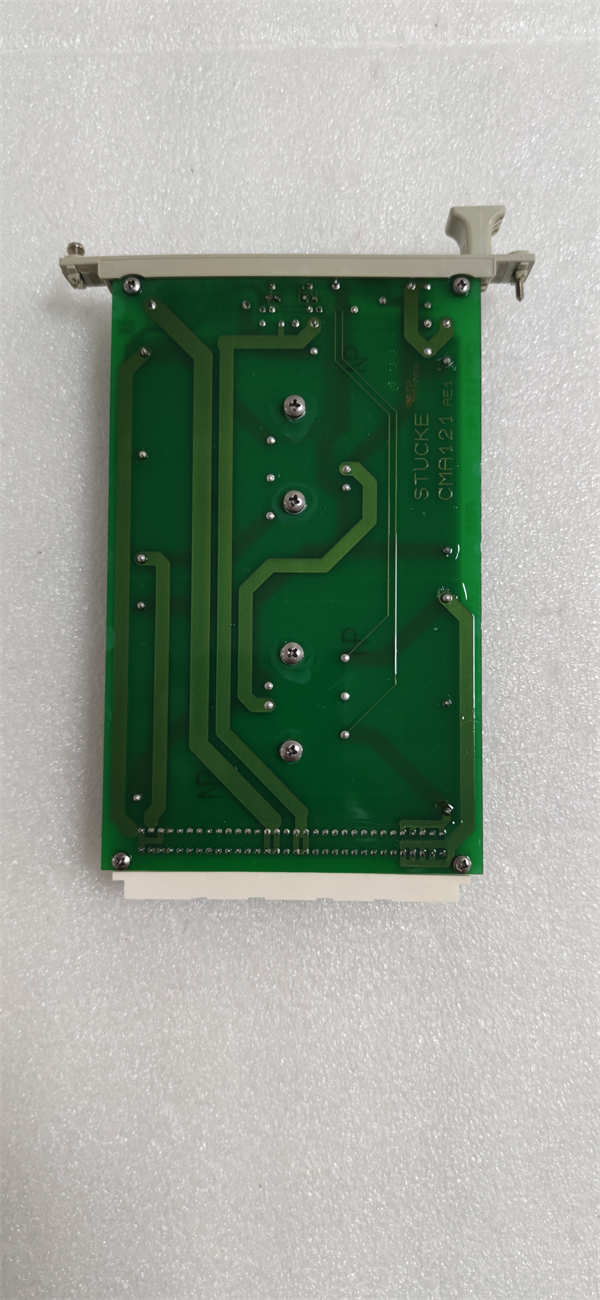

| Product model | CMA121 |

| Manufacturer | ABB |

| Product category | Communication Module (for industrial control systems) |

| Communication interfaces | 2 x Ethernet ports (10/100 Mbps) |

| Supported protocols | Modbus TCP/IP, Ethernet/IP, PROFINET IO |

| Power supply | 24 VDC ±10% |

| Power consumption | Max 3 W |

| Operating temperature range | 0°C to +60°C |

| Storage temperature range | -40°C to +85°C |

| Dimensions (LxWxH) | 100 mm x 80 mm x 40 mm |

| Mounting type | DIN rail (35mm) |

| Protection class | IP20 |

| Vibration resistance | 10-500 Hz, 10 m/s² |

ABB CMA121

Product introduction

The ABB CMA121 is a compact, multi-protocol communication module designed to facilitate seamless data exchange between industrial control systems and field devices. As part of ABB’s Advant OCS (Open Control System) ecosystem, CMA121 acts as a critical bridge, enabling interoperability between PLCs, DCSs, and third-party equipment in complex automation environments.

Equipped with dual Ethernet ports and support for industry-standard protocols like Modbus TCP/IP and PROFINET IO, CMA121 eliminates communication barriers in mixed-vendor setups. Its plug-and-play design simplifies integration into existing systems, making it ideal for retrofits or new installations. Whether in manufacturing lines, water treatment plants, or energy facilities, CMA121 ensures real-time data transmission, enhancing system visibility and control responsiveness.

Core advantages and technical highlights

Multi-protocol flexibility: The CMA121 supports three major industrial protocols—Modbus TCP/IP, Ethernet/IP, and PROFINET IO—without hardware reconfiguration. This versatility allows it to connect ABB’s AC800M PLCs with Rockwell Allen-Bradley drives or Siemens S7 controllers in the same network. For example, in an automotive plant with mixed equipment, CMA121 enables the central DCS to monitor both ABB robots and third-party conveyors, streamlining production oversight.

Dual-port redundancy: With two Ethernet ports, CMA121 supports ring topology configurations, ensuring network redundancy. If one port fails, data automatically reroutes through the second port, minimizing downtime. In a chemical processing plant where unplanned outages risk safety, this redundancy feature reduces failure-related losses by up to 90% compared to single-port modules.

Robust industrial design: Built to withstand harsh conditions, CMA121 operates reliably in temperatures from 0°C to +60°C and resists vibrations up to 10 m/s². Its IP20 rating protects internal components from dust, while surge protection on communication lines guards against electrical noise. This durability makes it suitable for installation near heavy machinery or in unconditioned industrial enclosures.

Low-latency performance: CMA121 achieves data transmission latencies below 10 ms, critical for time-sensitive applications like motion control synchronization. In a packaging line where precise coordination between filling machines and labelers is required, this low latency ensures actions are triggered within milliseconds of sensor inputs, reducing product waste.

Typical application scenarios

In municipal water treatment plants, CMA121 connects ABB’s AC500 PLCs with SCADA systems and third-party flow meters. It translates Modbus signals from the meters into PROFINET for the PLC, enabling real-time monitoring of water flow rates and chemical dosing levels. During peak demand, CMA121 ensures the SCADA system receives instant alerts if flow rates exceed thresholds, allowing operators to adjust pumps before overflows occur.

Food and beverage factories utilize CMA121 to integrate legacy equipment with modern MES (Manufacturing Execution Systems). For instance, a dairy plant with older pneumatic fillers (communicating via Modbus) and new ABB pasteurizers (using PROFINET) relies on CMA121 to unify data streams. This integration provides the MES with a holistic view of production, optimizing batch scheduling and reducing changeover times by 15%.

Renewable energy farms, such as solar parks, deploy CMA121 to link inverter systems with grid management platforms. It converts inverter data (via Ethernet/IP) into Modbus TCP for the central control system, enabling remote monitoring of power output and rapid response to grid frequency changes. This ensures compliance with utility regulations while maximizing energy feed-in efficiency.

Related model recommendations

CMA111: A single-protocol variant of CMA121, supporting only Modbus TCP/IP, ideal for simpler networks with uniform equipment.

CI854A: ABB’s PROFIBUS DP module, often paired with CMA121 in hybrid networks requiring both Ethernet and fieldbus connectivity.

AC800M: ABB’s modular PLC, which integrates seamlessly with CMA121 for enhanced communication capabilities in large-scale DCS systems.

TB521: ABB’s terminal block accessory, simplifying wiring between CMA121 and field devices while providing surge protection.

CMA131: An upgraded version of CMA121 with Gigabit Ethernet ports, designed for high-bandwidth applications like video surveillance integration in smart factories.

PM564: ABB’s AC500 PLC CPU, which uses CMA121 to extend communication reach to remote I/O modules in distributed installations.

CI858: ABB’s Ethernet/IP module, complementary to CMA121 in networks requiring redundant protocol handling for critical processes.

ABB CMA121

Installation, commissioning and maintenance instructions

Installation preparation: Before installing CMA121, ensure the DIN rail is clean, level, and grounded to minimize electrical noise. Use ESD-safe tools and anti-static wristbands to prevent damage to internal components. Verify the 24 VDC power supply is fused (1A) and isolated from high-voltage circuits. For redundant setups, mount CMA121 within 1 meter of the connected PLC to reduce cable length and signal loss. Label Ethernet cables clearly to avoid cross-connection during commissioning.

Maintenance suggestions: Inspect CMA121 quarterly for loose connections or dust accumulation; clean vents with compressed air (max 5 bar) to maintain cooling. Monitor network diagnostics via ABB’s Control Builder M software to check for packet loss or latency spikes—values exceeding 20 ms may indicate cable degradation. When replacing components, use only genuine ABB Ethernet cables (Cat 5e or higher) to preserve signal integrity. Firmware updates for CMA121 should be performed annually via the service port to access the latest protocol enhancements.

Service and guarantee commitment

ABB backs CMA121 with a 2-year warranty covering defects in materials and workmanship, including free replacement of faulty units. Customers benefit from 24/7 technical support via ABB’s global service network, with response times within 4 hours for critical issues.

Optional service contracts include on-site commissioning assistance and proactive firmware management, ensuring CMA121 operates at peak performance. ABB guarantees spare parts availability for 10 years post-production, minimizing long-term maintenance risks. This commitment reflects confidence in CMA121’s reliability and ensures customers receive consistent support throughout the product lifecycle.