Description

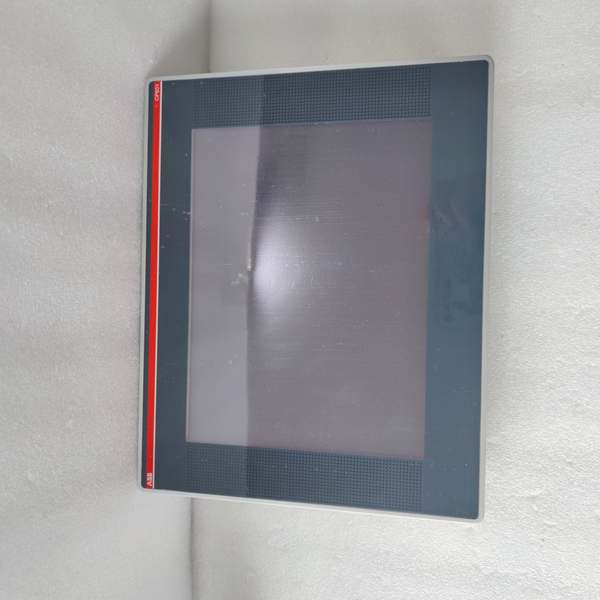

ABB CP651

-

Model Number: CP651 -

Manufacturer: ABB -

Product Type: PLC CPU Module -

Processor: 32-bit RISC (50 MHz clock speed) -

User Memory: 512KB flash (program storage), 64KB RAM (data storage) -

I/O Capacity: Up to 256 points (via CP600 series digital/analog I/O modules) -

Communication Ports: 1x RS-232 (programming/diagnostics), 1x RS-485 (Modbus RTU), 1x 10/100Mbps Ethernet (TCP/IP, Modbus TCP) -

Programming Software: ABB PG600 (compatible with IEC 61131-3 languages: LD, FBD, ST) -

Power Supply: 24V DC (±10% tolerance, 150mA typical consumption) -

Operating Temperature: 0°C to +55°C -

Storage Temperature: -25°C to +70°C -

Protection Rating: IP20 (panel-mount, finger-safe terminals) -

Dimensions: 90mm x 100mm x 75mm (WxHxD, DIN-rail mountable) -

Weight: 0.3kg

ABB CP651