Description

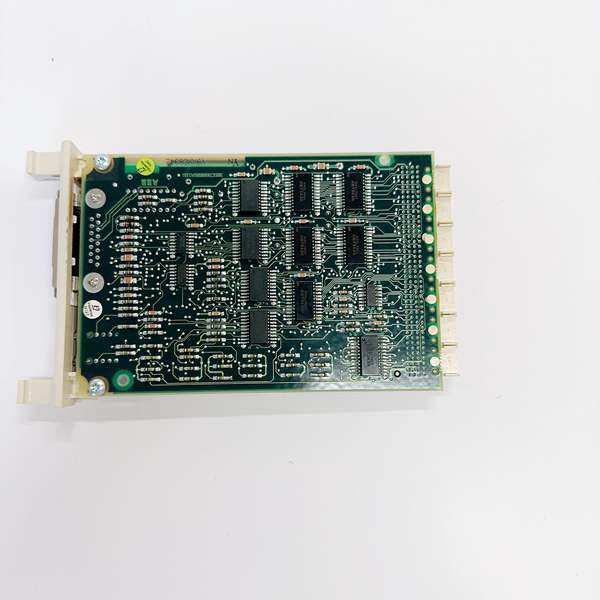

ABB CS513AK01 3BSE091971R1

-

Model Number: CS513AK01 3BSE091971R1 -

Manufacturer: ABB -

Product Type: CANopen Communication Module -

Protocol Support: CANopen DS301 (communication profile), DS402 (drives/ motion control) -

Baud Rate: 10kbps, 20kbps, 50kbps, 125kbps, 250kbps, 500kbps, 1Mbps (configurable) -

Number of Nodes: Up to 127 devices per CANopen network segment -

Data Capacity: 8 bytes per PDO (standard), 64 bytes per PDO (extended); 128 SDO transactions/sec -

Power Supply: 24V DC (±10% tolerance, drawn from AC500 controller backplane) -

Operating Temperature: -25°C to +55°C -

Storage Temperature: -40°C to +70°C -

Electrical Isolation: 500Vrms (channel-to-bus, channel-to-ground) -

Connector Type: 9-pin D-sub (male, for CANopen bus connection) -

Dimensions: 30mm x 100mm x 120mm (WxHxD, fits AC500 controller slot) -

Weight: 0.15kg

ABB CS513AK01 3BSE091971R1