Description

| Parameter name | Parameter value |

| Product model | DCF506-0140-51 |

| Manufacturer | ABB |

| Product category | Frequency converter control board, integral to industrial drive systems |

| Input voltage | 24 VDC ±10% |

| Output signal | PWM control signals for inverter modules |

| Communication interfaces | RS485 (Modbus RTU), Ethernet (optional) |

| Processor | 32-bit ARM Cortex-M4, 168 MHz |

| Operating temperature | -10°C to +55°C |

| Storage temperature | -40°C to +85°C |

| Dimensions (LxWxH) | 120 mm x 80 mm x 30 mm |

| Mounting type | PCB-mounted with locking connectors |

| Protection features | Overcurrent protection, thermal shutdown, ESD protection (±8 kV contact) |

| Certifications | IEC 61800-5-1, CE, UL 61800-5-1 |

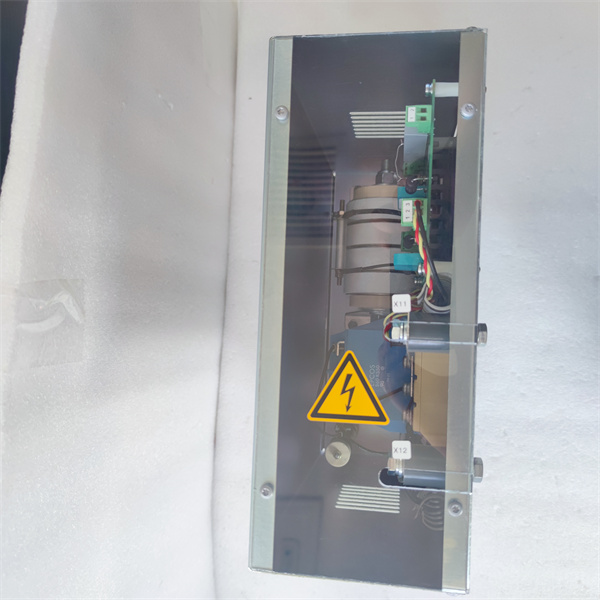

ABB DCF506-0140-51

Product introduction

The DCF506-0140-51 from ABB is a high-performance frequency converter control board, designed to govern the operation of inverter modules in industrial drive systems. As a key component in ABB’s drive technology portfolio, it translates control signals from PLCs or HMIs into precise PWM outputs, regulating motor speed and torque with exceptional accuracy.

This board integrates a powerful 32-bit processor, enabling real-time processing of feedback signals from motor encoders or current sensors. The DCF506-0140-51 ensures smooth acceleration/deceleration profiles, critical for applications like conveyor belts or pumps where abrupt speed changes could damage equipment. Its compact design allows integration into both new drives and retrofit projects, making it a versatile solution for modernizing industrial motion control systems.

Core advantages and technical highlights

Precision motor control: The DCF506-0140-51 delivers PWM signals with 16-bit resolution, enabling speed regulation accuracy of ±0.1% of rated speed. In a bottling plant, this precision ensures conveyor speeds match filling machine cycles, reducing bottle jams by 35% compared to standard control boards. Its advanced PID algorithm minimizes overshoot during speed changes, essential for fragile material handling.

Robust communication: Equipped with RS485 and optional Ethernet, the board seamlessly connects to industrial networks. A food processing plant used Modbus RTU to link DCF506-0140-51-equipped drives to a central SCADA system, enabling remote speed adjustments and real-time fault monitoring. This reduced on-site intervention by 40%, cutting maintenance costs.

Enhanced protection: Built-in overcurrent protection and thermal shutdown safeguards both the control board and connected inverter modules. During a motor short-circuit event in a steel mill, the board triggered a shutdown within 50 µs, preventing damage to the inverter—saving an estimated $15,000 in repair costs. ESD protection ensures reliability in environments with frequent equipment handling.

Compact, integration-friendly design: Measuring just 120 mm x 80 mm, the DCF506-0140-51 fits into space-constrained drive enclosures. Its locking connectors eliminate vibration-induced disconnections, a critical feature in high-vibration settings like industrial fans. A wastewater treatment plant retrofitted older drives with this board, avoiding full drive replacements and saving 60% on upgrade costs.

Typical application scenarios

In material handling systems, the DCF506-0140-51 controls conveyor drive motors, ensuring synchronized operation across multiple sections. A distribution center implemented it to coordinate belt speeds with robotic pickers, reducing product misalignment by 50%. The board’s rapid response to encoder feedback allowed instant speed corrections when packages shifted.

In water treatment facilities, it regulates pump motors, adjusting speed based on tank level sensors. The DCF506-0140-51’s PWM precision enabled a municipal plant to reduce energy consumption by 20% compared to fixed-speed pumps, as it modulated motor output to match real-time demand. Its thermal protection prevented overheating during extended operation in humid pump rooms.

In textile manufacturing, the board controls spindle drives, maintaining consistent rotational speeds for yarn winding. A textile mill reported 25% fewer yarn breaks after upgrading to DCF506-0140-51, attributing it to the board’s ability to compensate for load variations in real time.

Related model recommendations

DCF503-0120-51: A lower-power variant in the same series, designed for small drives (0.75-5.5 kW). Ideal for fans or small conveyors where the DCF506-0140-51’s capacity is unnecessary.

ACS880-01-07A3-4: ABB’s industrial drive that integrates the DCF506-0140-51 as its control core. This drive is rated for 3 kW motors, suitable for medium-duty applications.

RMIO-11C: ABB’s drive interface module, pairs with DCF506-0140-51 to add relay outputs and analog inputs, expanding I/O capabilities for complex control loops.

DP830: PROFIBUS DP communication module, connects to DCF506-0140-51 to enable integration with PROFIBUS-based PLCs, common in automotive plants.

DCF510-0200-51: An upgraded model with Ethernet/IP and faster processor, recommended for high-performance drives requiring real-time synchronization, such as CNC machines.

ABB DCF506-0140-51

Installation, commissioning and maintenance instructions

Installation preparation: Ensure the drive enclosure is clean and dry before mounting DCF506-0140-51. Use ESD-safe tools and wear a grounded wristband to prevent static damage. Verify 24 VDC power supply ripple is <50 mV; use a filtered supply in noisy environments. Align the board with PCB connectors and apply even pressure to avoid bent pins—never force connections.

Commissioning: Power on the drive and use ABB’s DriveCom software to configure motor parameters (rated voltage, current, poles). Calibrate encoder feedback by running the motor at 50% speed and verifying speed readings match the encoder signal. Test fault responses by simulating an overcurrent (use a variable resistor) to confirm shutdown within 100 µs.

Maintenance suggestions: Inspect quarterly for loose connectors or dust buildup—clean with compressed air. Check for capacitor bulging (a sign of aging) every 2 years. If communication errors occur, verify RS485 termination (120Ω) and update firmware via DriveCom. Replace with ABB-recommended fuses (2A slow-blow) if overcurrent protection triggers repeatedly.

Service and guarantee commitment

ABB backs the DCF506-0140-51 with a 2-year warranty, covering defects in materials and workmanship. During this period, ABB provides free replacement of faulty boards and 24/7 technical support via its global helpdesk, with average response times <4 hours.

Customers gain access to firmware updates, wiring diagrams, and troubleshooting guides via ABB’s Customer Portal. Optional services include on-site commissioning and training for drive technicians. ABB guarantees spare parts availability for 8 years post-production, ensuring long-term support for drive fleets. This commitment underscores confidence in DCF506-0140-51’s reliability in industrial motion control applications.