Description

Detailed parameter table

| Parameter name | Parameter value |

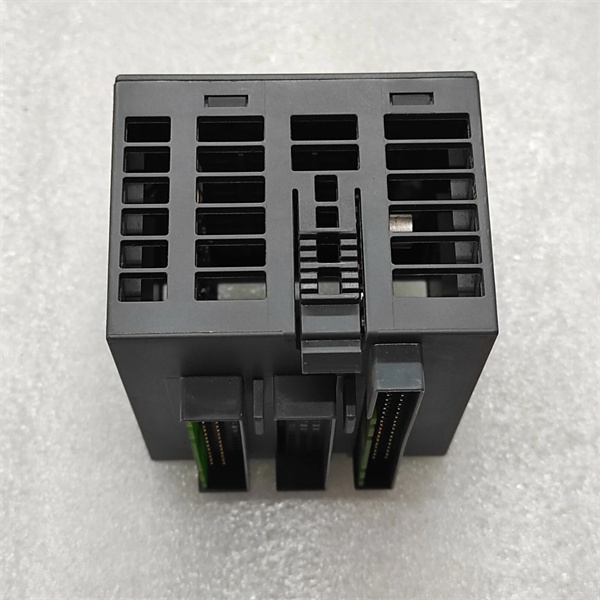

| Product model | DI524 1SAP240000R0001 |

| Manufacturer | ABB |

| Product category | Digital input module |

| Number of input channels | 16 isolated digital inputs |

| Input voltage range | 24 V DC |

| Input current | 3 mA per channel (typical) |

| Response time | ≤ 1 ms |

| Isolation | 2.5 kV AC between channels and backplane |

| Operating temperature range | -25°C to +60°C |

| Protection class | IP20 (when installed in control cabinet) |

| Dimensions (W×H×D) | 100 mm × 160 mm × 80 mm (approx.) |

| Weight | 0.3 kg (approx.) |

| Compatibility | ABB AC800M PLC system, compatible with ABB 3BSE018741R15 processor module |

| Mounting | DIN rail mounting (35 mm) |

| Certification | CE, UL, IECEx |

ABB DI524 1SAP240000R0001

Product introduction

The ABB DI524 1SAP240000R0001 is a high-performance digital input module designed to seamlessly integrate with ABB’s industrial control systems, particularly the AC800M PLC system. As a critical component in data acquisition, this module specializes in collecting digital signals from various field devices, converting them into a format understandable by the central processor, and facilitating real-time monitoring and control in industrial automation processes.

Featuring 16 isolated input channels, the ABB DI524 1SAP240000R0001 can connect to a wide range of digital sensors and switches, such as limit switches, photoelectric sensors, and emergency stop buttons. When paired with a powerful processor module like the ABB 3BSE018741R15, it forms a robust data collection and processing unit, ensuring that critical on/off status information from the field is accurately and promptly transmitted to the control system. This makes the ABB DI524 1SAP240000R0001 an indispensable part of automation systems in manufacturing, energy, and process industries.

Core advantages and technical highlights

High-speed signal acquisition

The ABB DI524 1SAP240000R0001 boasts an ultra-fast response time of ≤ 1 ms, enabling it to capture even the most rapid changes in digital signals. This is crucial in time-sensitive applications where delayed signal detection could lead to process errors or safety hazards. For example, in a high-speed packaging line, the module can instantly detect when a product reaches a sealing station via a proximity sensor, transmitting this signal to the ABB 3BSE018741R15 processor module, which then triggers the sealing mechanism without delay, ensuring precise synchronization and high production efficiency.

Enhanced electrical isolation

With 2.5 kV AC isolation between channels and the backplane, the ABB DI524 1SAP240000R0001 provides exceptional protection against electrical interference and ground loops. This isolation prevents noise from affecting signal integrity, ensuring accurate signal transmission even in environments with high electromagnetic interference, such as near large motors or welding equipment. In a steel mill, for instance, where heavy machinery generates significant electrical noise, the module’s robust isolation ensures that signals from conveyor belt limit switches are reliably detected, preventing false triggers and ensuring safe operation.

Flexible integration and scalability

The ABB DI524 1SAP240000R0001 is fully compatible with ABB’s AC800M PLC system, allowing for plug-and-play integration with processor modules like the ABB 3BSE018741R15. Its compact design and DIN rail mounting enable easy installation in control cabinets, saving space and simplifying system layout. Moreover, multiple ABB DI524 1SAP240000R0001 modules can be deployed in parallel to expand the number of input channels, accommodating the growing needs of industrial automation projects. This scalability makes it suitable for both small-scale systems and large, complex installations.

ABB DI524 1SAP240000R0001

Typical application scenarios

In automotive manufacturing plants, the ABB DI524 1SAP240000R0001 is widely used to monitor the status of various equipment on the assembly line. It connects to photoelectric sensors that detect the presence of car body parts on conveyor belts, limit switches that indicate the position of robotic arms, and emergency stop buttons along the production line. The module collects these digital signals and sends them to the ABB 3BSE018741R15 processor module, which uses the information to coordinate the movement of conveyors and robots. For example, when a sensor detects that a car door is properly positioned on the assembly line, the ABB DI524 1SAP240000R0001 transmits this signal to the processor, which then instructs the robotic arm to start attaching the door, ensuring precise and efficient assembly.

In water treatment facilities, the ABB DI524 1SAP240000R0001 plays a key role in monitoring the operation of pumps, valves, and filtration systems. It connects to float switches in water tanks to detect liquid levels, pressure switches on pumps to indicate operational status, and limit switches on valve actuators to confirm open/closed positions. By continuously collecting these signals and sending them to the central processor, the module enables the control system to respond quickly to changes, such as activating a backup pump when a low-level float switch is triggered or shutting down a filter when a pressure switch indicates a blockage. This ensures the reliable operation of water treatment processes and compliance with quality standards.

In food and beverage processing plants, the ABB DI524 1SAP240000R0001 is employed to monitor safety interlocks and equipment status. It connects to door interlock switches on mixing machines and filling equipment, ensuring that these machines cannot operate when access doors are open, protecting workers from injury. The module also monitors the status of conveyor belt motors via thermal overload switches, alerting the control system if a motor overheats. By working in tandem with the ABB 3BSE018741R15 processor, it helps maintain a safe working environment and prevents costly equipment damage, ensuring uninterrupted production of food and beverage products.

Related model recommendations

- ABB DO524 1SAP240001R0001: A digital output module that complements the ABB DI524 1SAP240000R0001, providing 16 output channels to control actuators, relays, and valves based on signals from the processor module.

- ABB AI523 1SAP240002R0001: An analog input module that works with the ABB DI524 1SAP240000R0001in mixed-signal systems, enabling the collection of continuous variables like temperature and pressure alongside digital signals.

- ABB AO523 1SAP240003R0001: An analog output module that pairs with the ABB DI524 1SAP240000R0001, allowing the control system to output variable signals (e.g., 4-20 mA) to control devices like variable speed drives.

- ABB 3BSE018741R15: A high-performance processor module that integrates seamlessly with the ABB DI524 1SAP240000R0001, processing the collected digital signals and executing control logic.

- ABB CI867K01 3BSE043660R1: An Ethernet communication module that, when used with the ABB DI524 1SAP240000R0001, enables remote transmission of digital input data to supervisory systems.

- ABB TU830V1: A terminal unit that simplifies wiring between field devices and the ABB DI524 1SAP240000R0001, organizing connections and reducing installation time.

- ABB DI521 1SAP240004R0001: A compact 8-channel digital input module, serving as a smaller alternative to the ABB DI524 1SAP240000R0001for applications with fewer input requirements.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the ABB DI524 1SAP240000R0001, ensure the control cabinet is clean, dry, and free from excessive vibration or electromagnetic interference. The ambient temperature must be within -25°C to +60°C, with relative humidity below 95% (non-condensing). Required tools include a screwdriver (PH2), wire strippers, and a torque wrench (set to 0.5 – 0.7 Nm for terminal connections). Disconnect the power supply to the control system before installation to avoid electrical hazards. Mount the module on a 35 mm DIN rail, ensuring it is securely fastened to prevent movement. Use twisted-pair shielded cables for input signals, with the shield grounded at both ends, to minimize interference. When wiring, ensure each channel is connected to the correct field device, following the labeling on the module and the system wiring diagram.

Maintenance suggestions

For daily maintenance of the ABB DI524 1SAP240000R0001, inspect the module regularly for dust buildup and clean it with a soft, dry cloth or compressed air (low pressure) to prevent overheating. Check the status LEDs on the module; a green light for each channel indicates a valid input signal, while a red light may indicate a fault. Periodically verify the tightness of terminal connections, as loose wires can cause intermittent signal loss. If a channel fails to detect a signal, first check the connected device and wiring; if these are functional, use a multimeter to test the channel’s input voltage. Replace the module with an ABB-approved spare if faulty. It is recommended to perform a functional test annually, simulating input signals to ensure all channels operate correctly.

Service and guarantee commitment

The ABB DI524 1SAP240000R0001 comes with a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. During this period, ABB will repair or replace faulty modules free of charge. Our global technical support team is available 24/7 to assist with installation guidance, troubleshooting, and technical inquiries via phone, email, or online chat.

We provide comprehensive online resources, including user manuals, wiring diagrams, and compatibility guides, to support efficient deployment of the ABB DI524 1SAP240000R0001. For enhanced support, optional service contracts offer on-site assistance, training sessions, and priority response times. ABB is committed to ensuring the reliability and performance of the ABB DI524 1SAP240000R0001, leveraging our expertise in industrial automation components to keep your control systems operating smoothly.